Open-type deep throat punching equipment

A technology of stamping equipment and deep throat, which is applied in the field of stamping, can solve problems such as difficult to meet production needs, and achieve the effect of solving limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings.

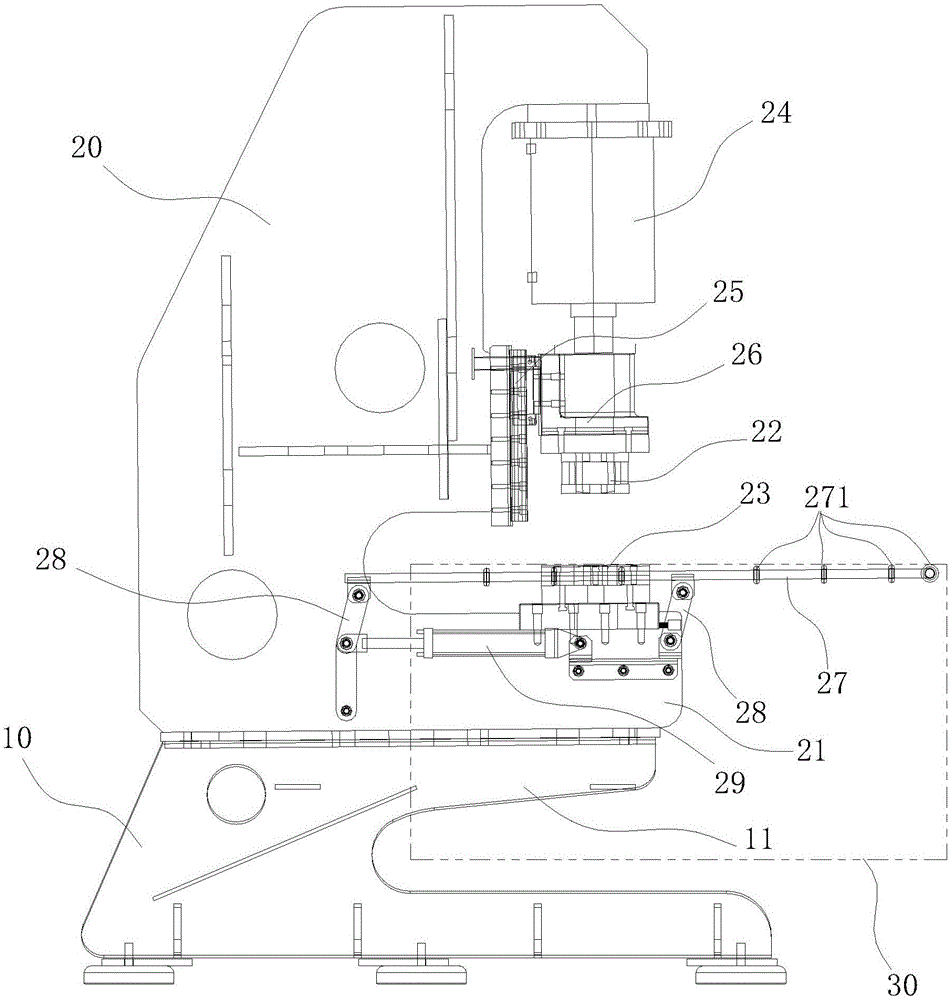

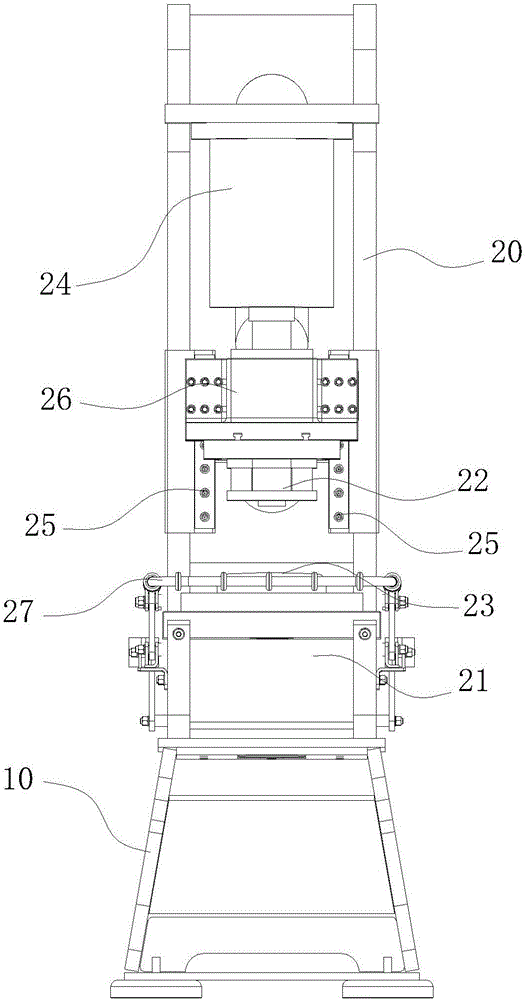

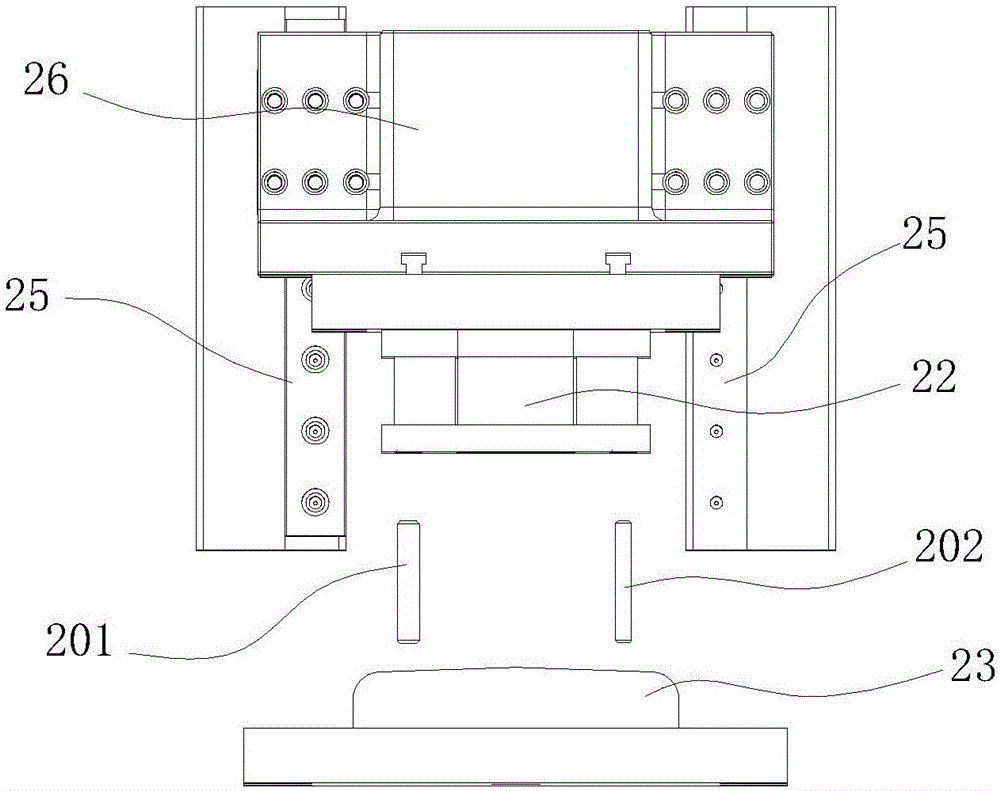

[0021] Such as figure 1 , 2 As shown, a kind of open deep throat stamping equipment, comprises base 10, frame 20, and upper die 22, lower die 23 and hydraulic cylinder 24 that are set on frame 20, and described lower die 23 is fixed relative to frame 20 Setting, the upper mold 22 is arranged to reciprocate in the vertical direction relative to the frame 20, and the upper and lower molds 22, 23 are vertically oppositely arranged, and the hydraulic cylinder 24 is used to drive the upper mold 22 to reciprocate, so The frame 20 is provided with a cantilever beam-type pallet 21, and the lower die 23 is installed on the pallet 21, so that the lower die 23 can horizontally extend into the interior of the cylindrical member 30. The lower die 23 of the present invention is arranged on a protruding structure. When the lower die 23 stretches into the inside of the cylindrical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com