Metal foil numerical control cutting and gluing direct forming additive manufacturing equipment and method

An additive manufacturing and metal foil technology, which is applied in the field of metal foil CNC cutting, gluing and direct forming additive manufacturing equipment, and can solve the problems of inability to form complex shapes, low efficiency, and thermal cracks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

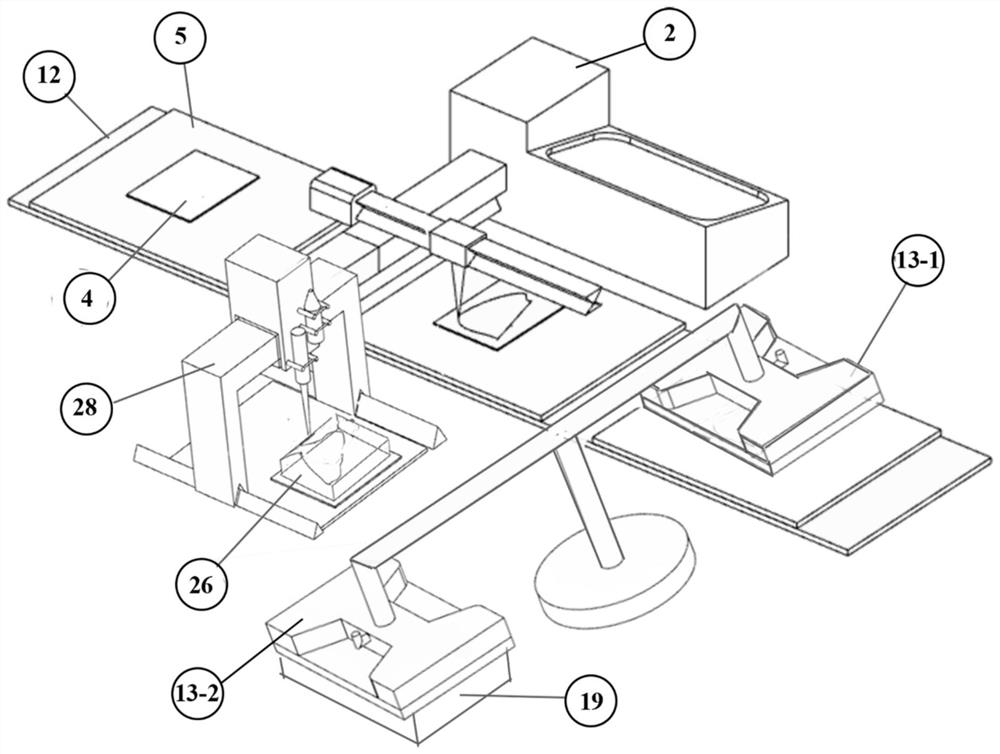

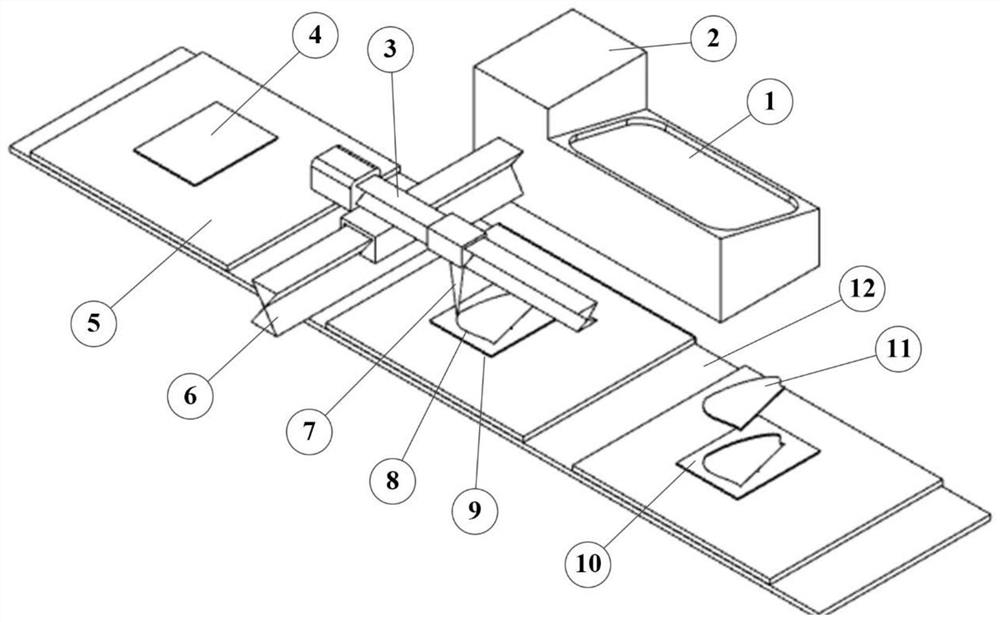

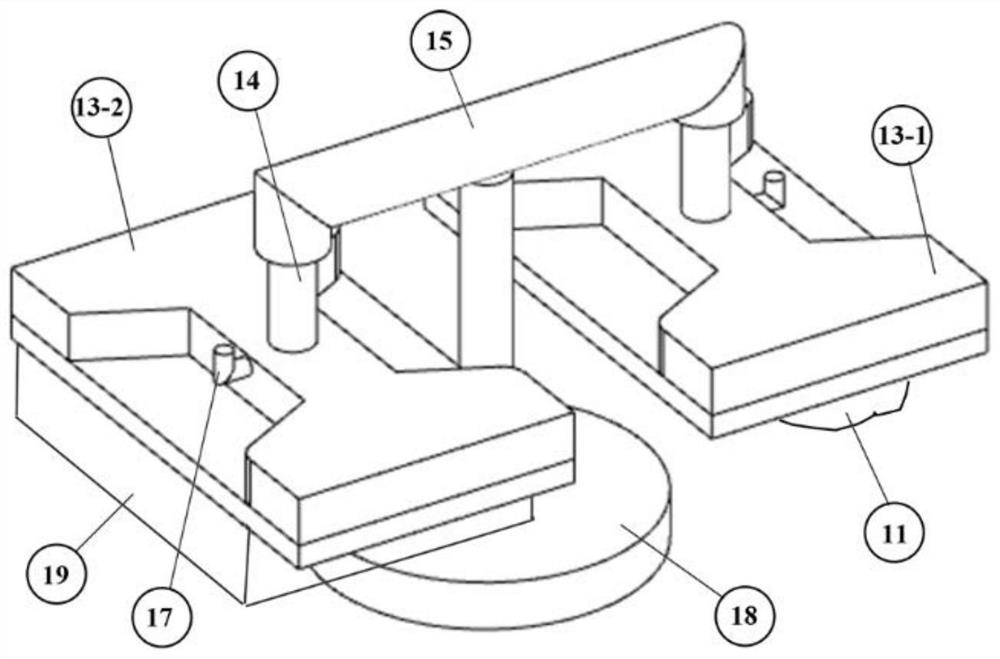

[0128] A metal foil CNC cutting and gluing direct molding additive manufacturing equipment, its overall structure schematic diagram is as follows figure 1 Therefore, a conveyor belt 12 is included, and the conveyor belt can control the transmission speed and circulation flow. A plurality of stainless steel plate processing tables 5 at equal distances are stuck on the conveyor belt. A laser cutting machine 2 is placed in the center of the conveyor belt. The laser cutting machine The experimental area can be passed by a conveyor belt. The laser cutting machine has a computer 1 that can be programmed or uploaded digitally. The laser cutting machine has a manipulator device 3, 6. The manipulator device includes an X axis 3 and a Y axis 6. , the X-axis and Y-axis are slidable axes, the X-axis of the manipulator has a rotatable laser beam 7, and a rotatable suction cup is placed on the side of the conveyor belt. The partial structure diagram of the device is as follows Figure 4 As ...

Embodiment 2

[0138] The device structure of the metal foil CNC cutting and gluing direct molding additive manufacturing technology in this embodiment is the same as that in Embodiment 1.

[0139] The additive manufacturing process of metal foil slices is the same as that of Example 1, the difference is that the GH4033 nickel-based superalloy metal foil is replaced with 316L stainless steel metal foil to carry out the additive manufacturing experiment of the thermos cup.

[0140] The experimental environment is the same as that of Example 1. A 316L stainless steel metal foil with a diameter of 100 mm and a thickness of 10 mm is placed in the center of the processing table, and is transported by a conveyor belt at a speed of 0.1 m / s, and is transmitted to the center of the laser cutting machine for 8 seconds. The processing route uploaded by the computer, the laser power is 10W, the scanning speed is 100mm / s, and the single-layer metal foil slice with a hollow layer is cut out for the thermos...

Embodiment 3

[0144] The device structure of the metal foil CNC cutting and gluing direct molding additive manufacturing technology in this embodiment is the same as that in Embodiment 1.

[0145] The additive manufacturing process of the metal foil slice is the same as that in Example 1, the difference is that the GH4033 nickel-based superalloy metal foil is replaced with the A356 aluminum alloy metal foil to carry out the additive manufacturing experiment of the wheel hub.

[0146] The experimental environment is the same as in Example 1. A356 aluminum alloy metal foil with a diameter of 550 mm and a thickness of 2 mm is placed in the center of the processing table, and is transported by a conveyor belt at a speed of 0.1 m / s, and is transmitted to the center of the laser cutting machine for 10 seconds. Program the processing route uploaded by the computer, the laser power is 10W, the scanning speed is 100mm / s, the hollow area of the wheel hub is cut out, and the schematic diagram of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com