Novel mosaic composition brake shoe and manufacturing method thereof

A technology for synthesizing brake shoes and manufacturing methods, applied in chemical instruments and methods, brake parts, brake types, etc., can solve problems such as thermal cracks in wheel treads, poor heat resistance, thermal recession, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

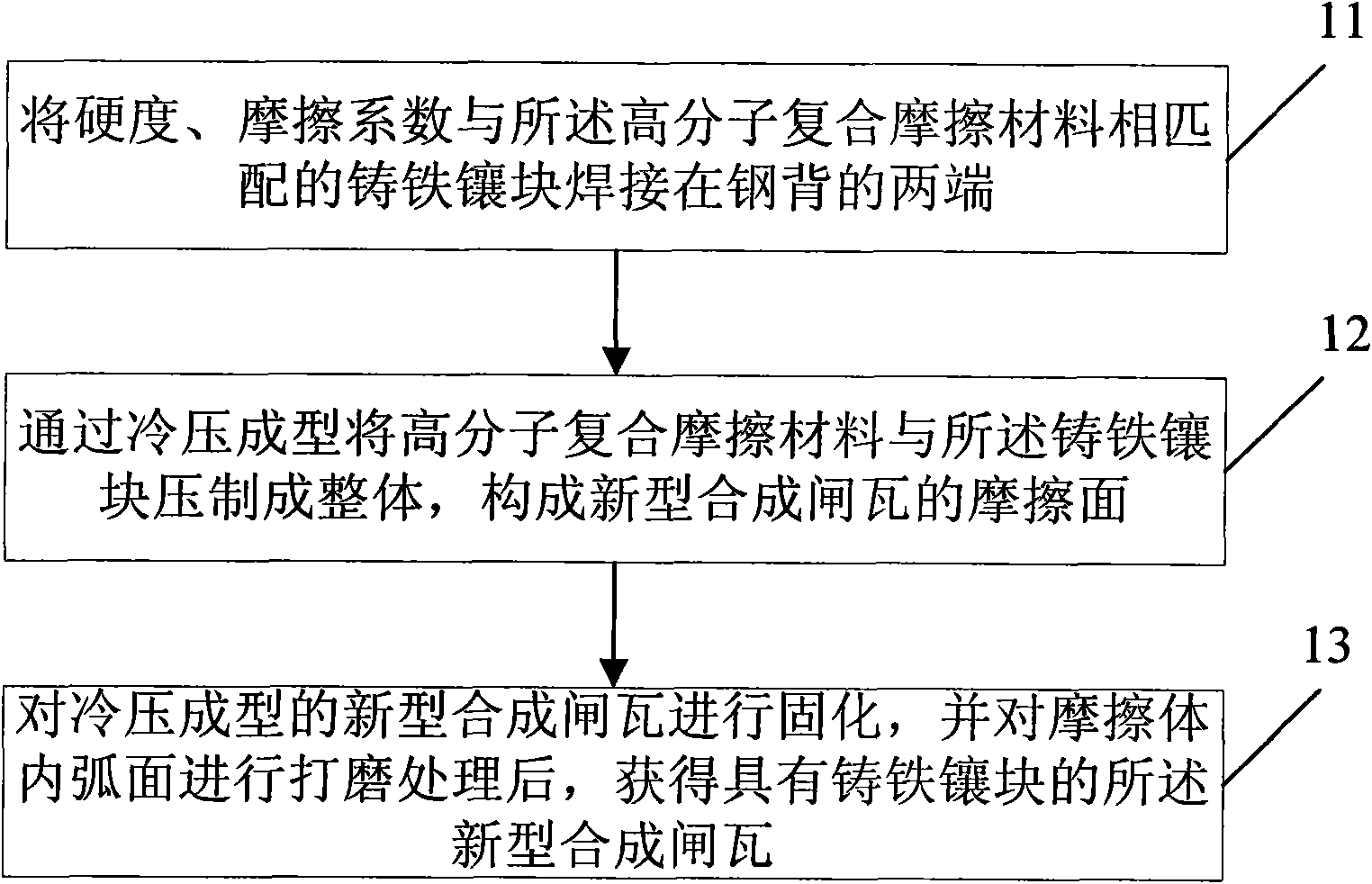

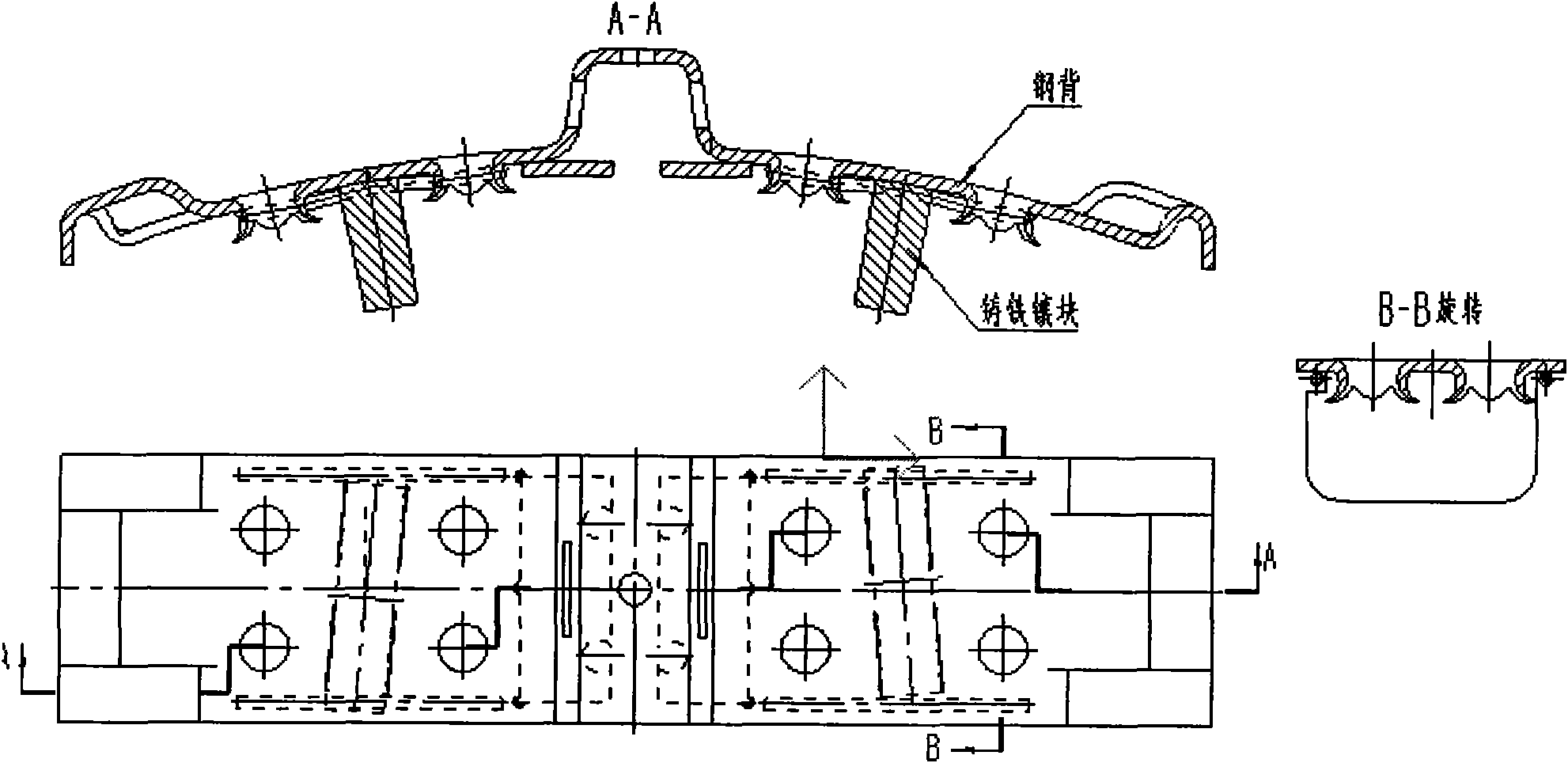

[0033] The embodiment of the present invention provides a new type of embedded composite brake shoe and its manufacturing method. Aiming at the respective advantages and disadvantages of cast iron brake shoes and synthetic brake shoes, polymer composite friction materials are effectively combined with cast iron inserts to integrate cast iron brake shoes and synthetic brake shoes. The respective advantages of synthetic brake shoes are integrated, which improves the comprehensive performance of high-friction synthetic brake shoes. The new synthetic brake shoe can significantly improve the thermal conductivity of the brake shoe, reduce the thermal degradation of the synthetic brake shoe, and ensure the stable friction performance of the synthetic brake shoe during braking; at the same time, it can effectively conduct the wheel tread and the brake shoe during the braking process. The friction heat generated by the friction body during the braking process reduces the thermal damage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com