Submerged-arc welding technology for 304L stainless steel thick plates

A welding process and submerged arc welding technology, applied in welding equipment, arc welding equipment, welding/welding/cutting items, etc., can solve the problems of intergranular corrosion, coarse grains, etc., and achieve good low-temperature impact toughness, uniform structure, Overcome the effect of coarse grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The submerged arc welding process steps of a kind of 304L stainless steel thick plate of the present invention comprise:

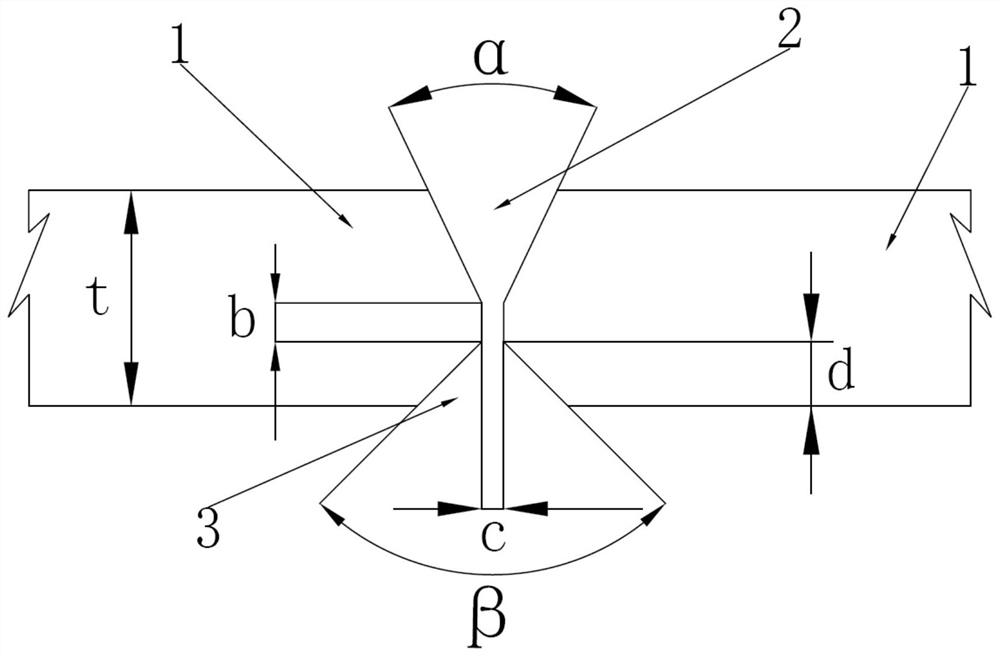

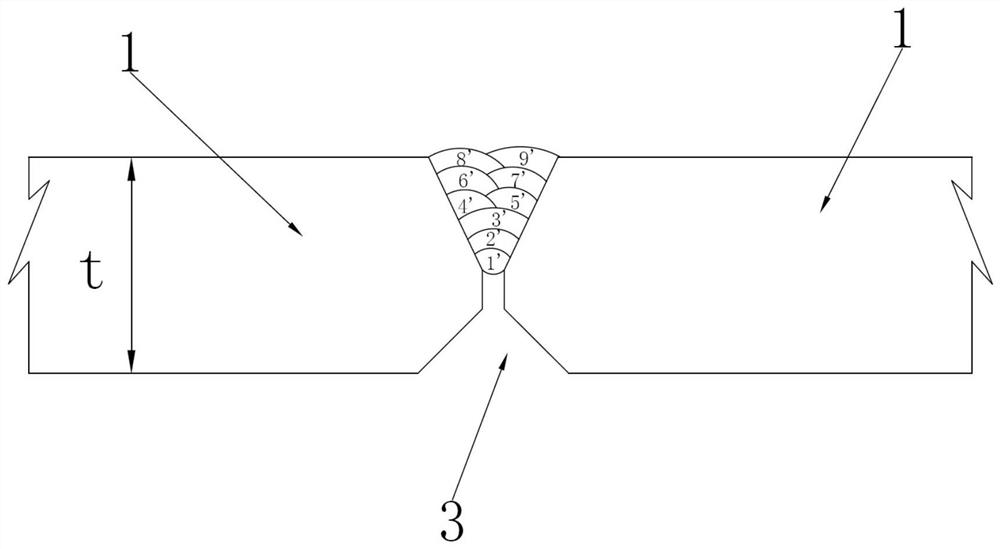

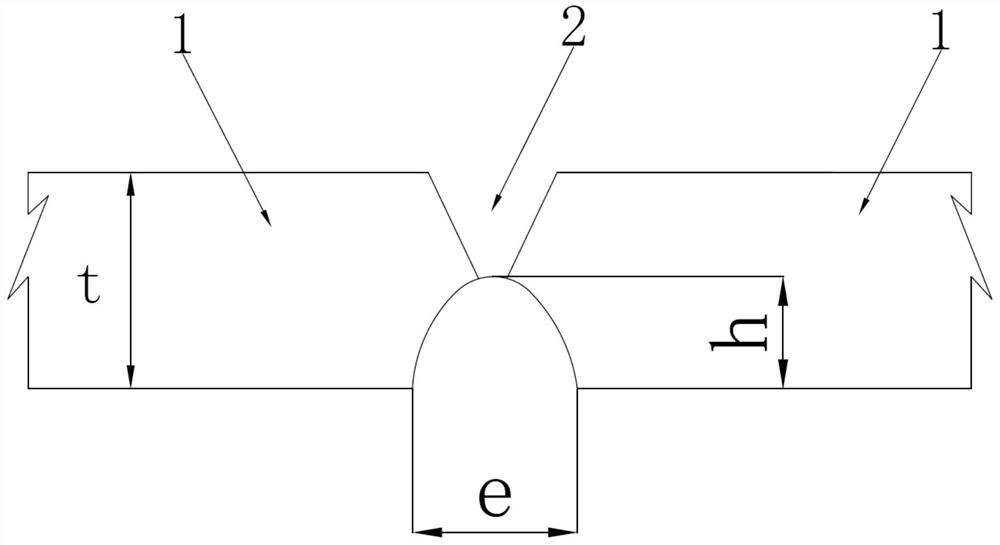

[0044] 1. Welding groove processing: two 304L stainless steel thick plates 1 with a length of 1000mm, a width of 200mm, and a thickness t of 45mm are machined into double-sided X-shaped grooves by machining, such as figure 1 As shown, the front groove angle α is 60°±5°, the blunt edge length b is 4mm~5mm, the groove gap c is 0mm~1mm, the back groove angle β is 70°±5°, and the back groove depth d 1 / 3t mm to 2 / 5t mm;

[0045] 2. Preparation before welding:

[0046] Select the welding wire and basic flux that match the 304L stainless steel plate 1 to be welded, and bake the basic flux at a temperature of 300-350°C for 2 hours; in this embodiment, The welding wire is GWS-316L welding wire with a diameter of 2.4mm~4.0mm, and its chemical composition and mass percentage meet: C: 0.015%~0.03%, Si: 0.57%~1.0%, Mn: 0.5%~2.5%, P:0.015 %~0.025%, S: 0.012%~0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com