Application of hydrophobic heat insulating and cooling film

A thermal insulation and cooling, hydrophobic technology, applied in the device, coating, special surface and other directions of coating liquid on the surface, can solve the problem of limiting the service life and thermal insulation effect of thermal insulation film products, efficiently dissipating and blocking sunlight and other problems, to achieve the effect of excellent sunlight reflection ability, strong absorption ability, and excellent cooling performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

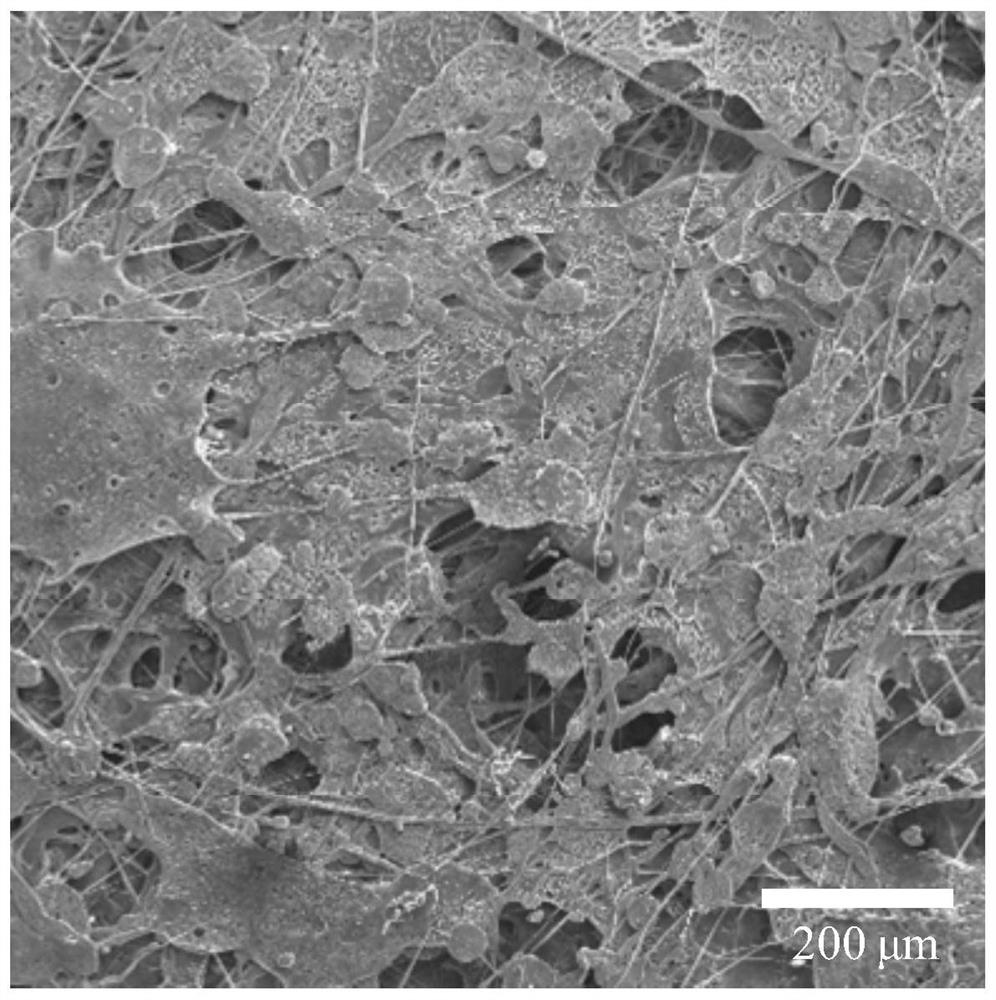

[0055] An application of a hydrophobic heat insulation and cooling film, specifically covering the surface of a substrate (a sunshade, specifically pongee fabric without a waterproof coating) with a hydrophobic heat insulation and cooling film, for reducing temperature, wherein the hydrophobic heat insulation and cooling membrane is a polymer porous membrane, which is formed by stacking polymer porous membranes.

[0056] In this example, the interior of the hydrophobic heat-insulating and cooling membrane is a sponge-like structure, and the pore diameters of the pores are distributed in a bimodal manner, with a wide distribution of 0.2 μm to 0.6 μm and 2 μm to 4.2 μm, respectively, and the holes pass through the holes on the walls of the holes. The nano-holes are connected.

[0057] In this embodiment, the porosity of the hydrophobic heat insulating and cooling film is 72.03%.

[0058] In this embodiment, the thickness of the hydrophobic heat insulating and cooling film is 11...

Embodiment 2

[0073]The application of a hydrophobic heat-insulating and cooling film is basically the same as in Example 1, except that the hydrophobic heat-insulating and cooling film used in Example 2 is a polymer porous film, which is formed by stacking polymer porous films.

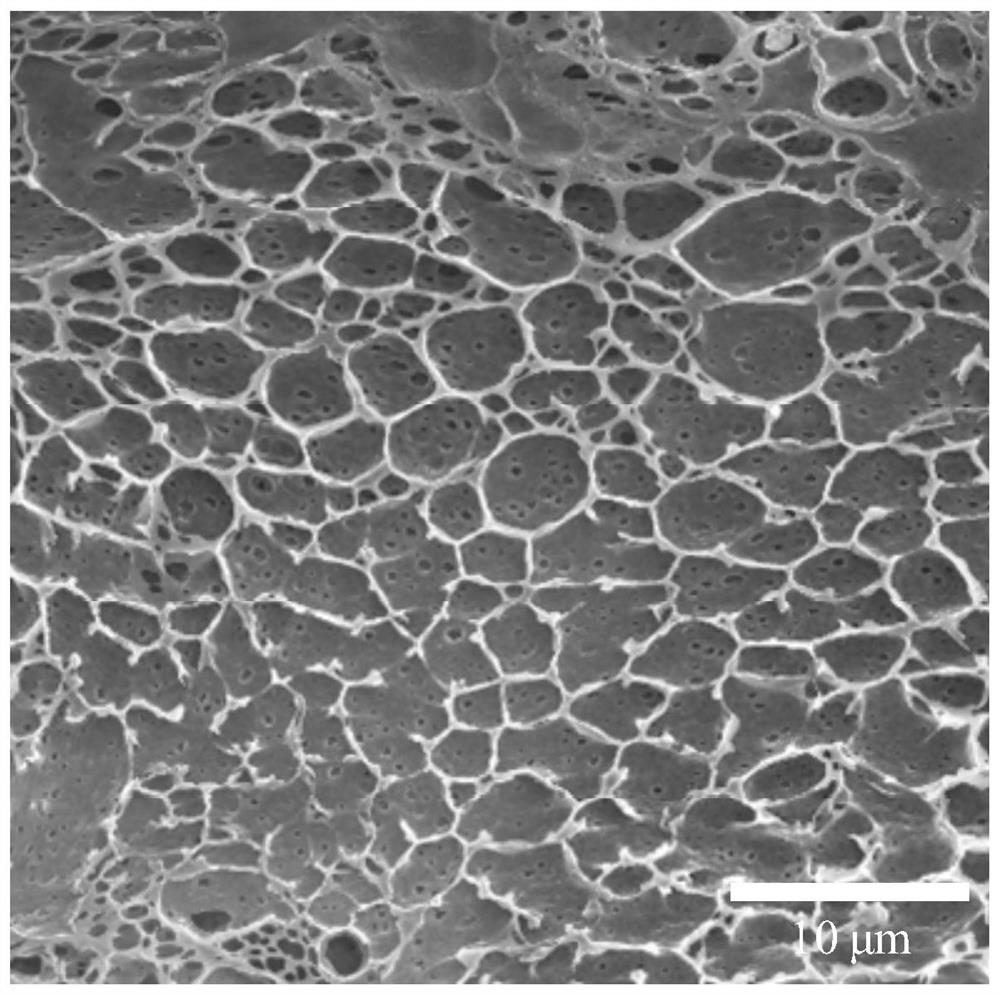

[0074] In this example, the interior of the hydrophobic heat-insulating and cooling membrane is a sponge-like structure, and the pore size of the pores is distributed in a bimodal manner. The nano-holes are connected.

[0075] In this embodiment, the porosity of the hydrophobic heat insulating and cooling film is 73.36%.

[0076] In this embodiment, the thickness of the hydrophobic heat insulating and cooling film is 1145 μm.

[0077] In this embodiment, the surface of the hydrophobic heat-insulating and cooling film has cell-shaped holes, and the cell-shaped holes are connected to each other through nanometer holes on the walls of the holes, and the diameter of the cell-shaped holes is 1 μm to 10 μm.

[0078] I...

Embodiment 3

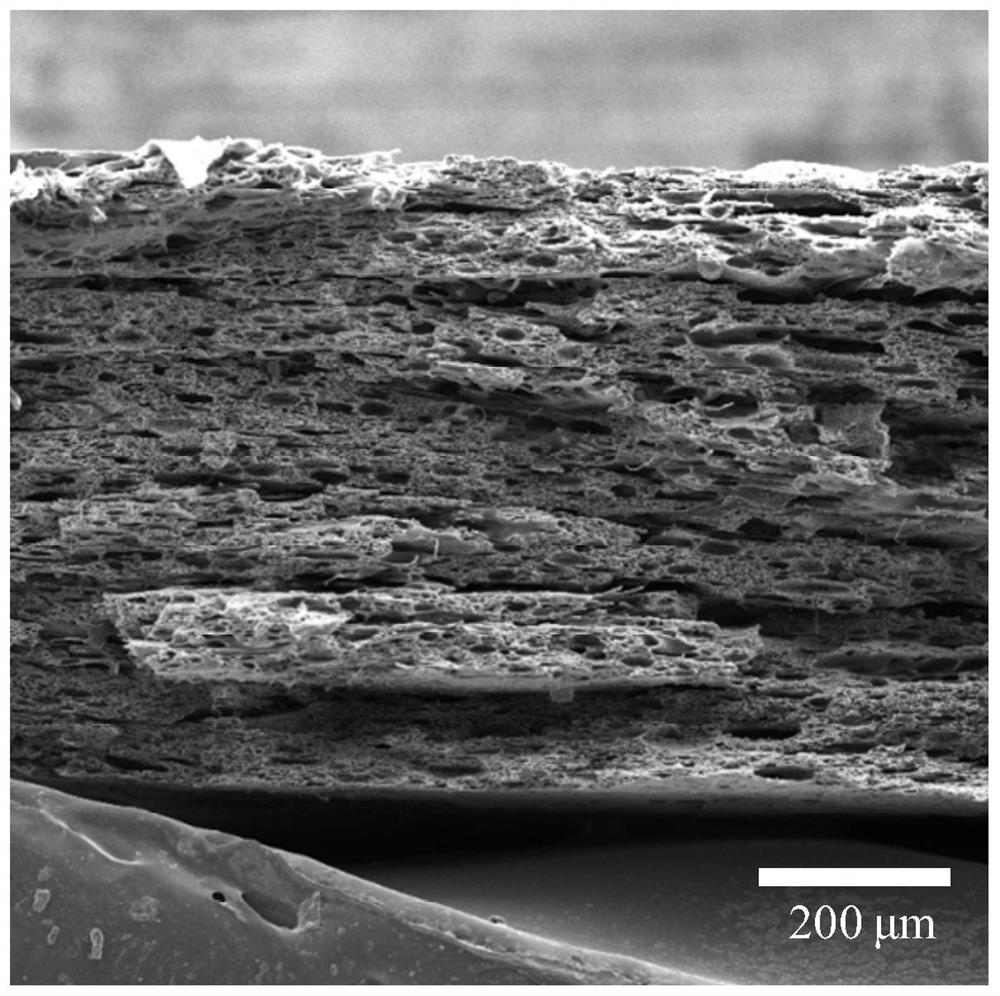

[0085] The application of a hydrophobic heat-insulating and cooling film is basically the same as in Example 1, except that the hydrophobic heat-insulating and cooling film used in Example 3 is a polymer porous film, which is formed by stacking polymer porous films.

[0086] In this example, the interior of the hydrophobic heat-insulating and cooling membrane is a sponge-like structure, and the pore diameters of the pores are distributed in a bimodal manner. The holes are connected.

[0087] In this embodiment, the porosity of the hydrophobic heat insulating and cooling film is 71.93%.

[0088] In this embodiment, the thickness of the hydrophobic heat insulating and cooling film is 1145 μm.

[0089] In this embodiment, the surface of the hydrophobic heat insulation and cooling film has cell-shaped holes, and the cell-shaped holes are connected to each other through nanometer holes on the walls of the holes, and the diameter of the cell-shaped holes is 5 μm to 10 μm.

[0090]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com