Modified coating for surface of transparent cover film, preparation method thereof and modified coating

A technology for modifying coatings and covering films, applied in the field of transparent flexible circuit boards, can solve the problems of high temperature fogging and deformation of transparent covering films, and achieve the effects of not easy precipitation, improving temperature resistance, and avoiding fogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] On the other hand, the embodiment of the present invention also provides a method for preparing a modified coating, comprising the following steps:

[0034] T01: According to the ingredients contained in the modified coating according to the present invention and their contents, the raw materials of each ingredient are weighed respectively;

[0035] T02: Mix the zirconia, photosensitive resin, pentaerythritol triacrylate, aliphatic hydrocarbon solvent and ketone solvent, and then filter to obtain the modified coating.

[0036] The preparation method provided by the present invention has simple process and low cost. After the modified coating obtained by the preparation method is coated on the surface of the base film layer of the transparent cover film to form a film, the temperature resistance of the base film layer of the transparent cover film can be improved. properties, so that the base material is not easy to be precipitated and thermally deformed under high tempe...

Embodiment 1

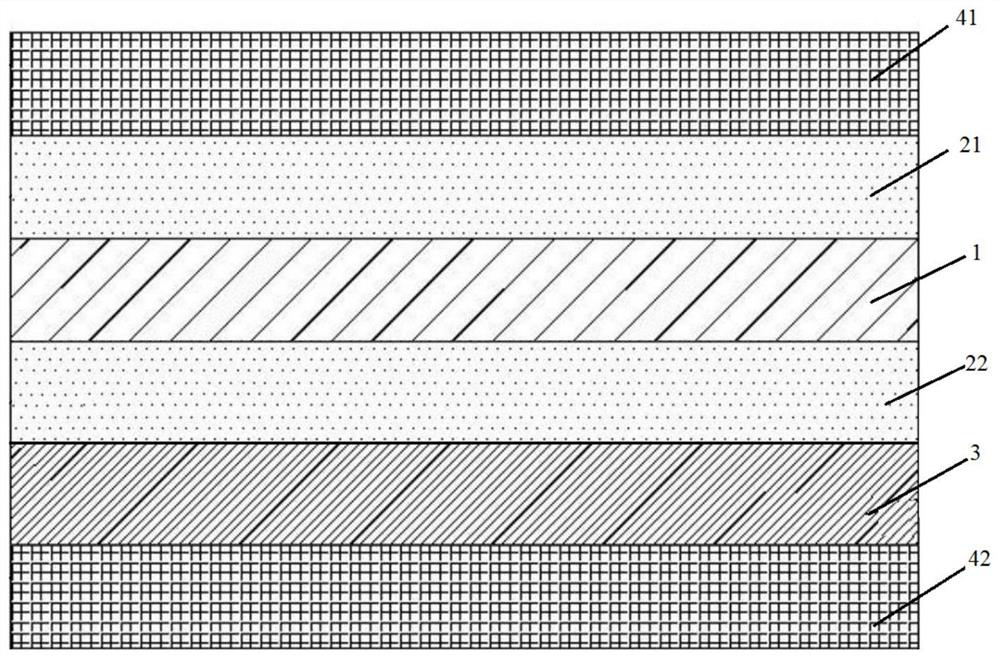

[0080] A transparent cover film, comprising a second release protective film, an adhesive layer, a second modified coating, a PET substrate film layer, a first modified coating and a first release protective film arranged sequentially from bottom to top membrane.

[0081] Wherein, the first modified coating and the second modified coating are obtained by coating and drying the modified coating, and the modified coating includes: 25% zirconia; 15% photosensitive resin; 1% pentaerythritol triacrylate; Heptane 20%, methyl-2-pentanone 10%, 1-methoxy-2-propanone 14%, and cyclohexanone 15%.

Embodiment 2

[0083] A transparent cover film, comprising a second release protective film, an adhesive layer, a second modified coating, a PET substrate film layer, a first modified coating and a first release protective film arranged sequentially from bottom to top membrane.

[0084] Wherein, the first modified coating and the second modified coating are obtained by coating and drying the modified coating, and the modified coating includes: 25% zirconia; 25% photosensitive resin; 1% pentaerythritol triacrylate; Heptane 10%, methyl-2-pentanone 15%, 1-methoxy-2-propanone 14%, and cyclohexanone 10%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com