Copolymer latex for negative electrode of lithium ion secondary battery, preparation method and application

A copolymer latex, lithium-ion battery technology, applied in secondary batteries, battery electrodes, circuits, etc., can solve the problems of low cohesion between electrode active materials and current collectors, affecting battery capacity, etc., and improve resistance to electrolyte swelling. The effect of improving the adhesion, reducing the dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~7

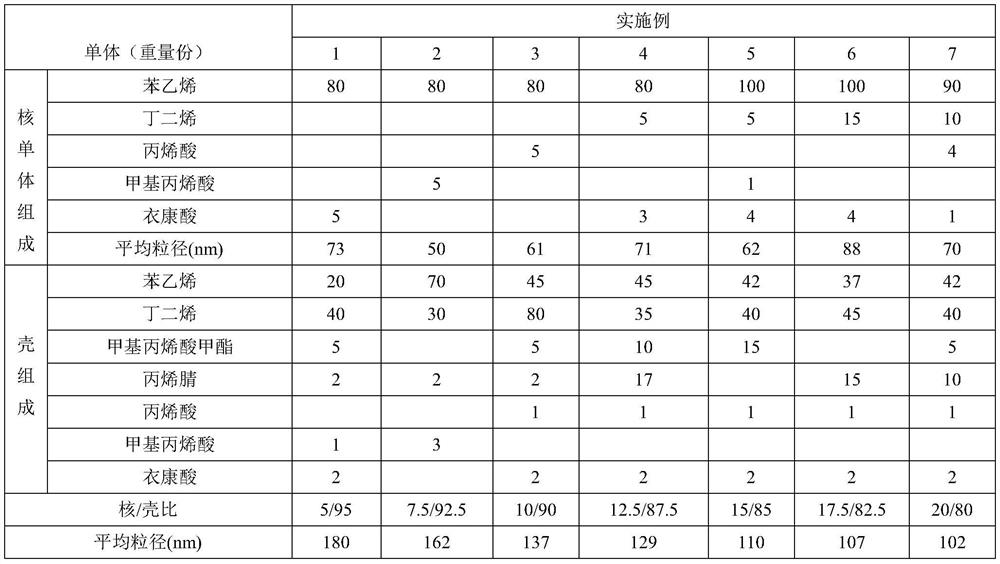

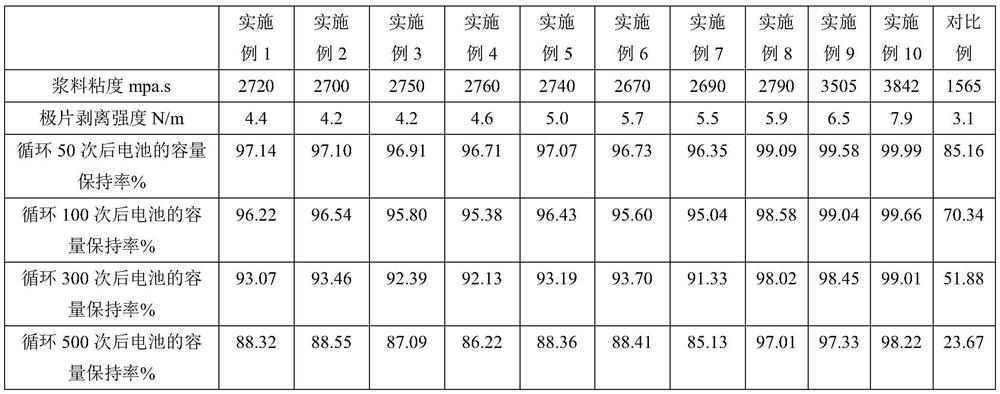

[0037] A kind of copolymer latex for negative electrode of lithium ion secondary battery, specific formula is shown in Table 1.

[0038] Produced by seed emulsion polymerization method, the specific method is as follows:

[0039] (1) fully stirring and mixing the styrene, butadiene, unsaturated carboxylic acid monomer and emulsifier, deionized water of formula quantity, obtains the core layer monomer pre-emulsion;

[0040] (2) butadiene, styrene, ethylenically unsaturated monomer of formula quantity are fully stirred and mixed with emulsifier and deionized water to obtain shell monomer pre-emulsion;

[0041] (3) After mixing 40% of the total mass of the nuclear layer monomer pre-emulsion obtained in step (1) with the first part of the pH regulator and the first part of the initiator, stir and heat up to 72 ° C, and keep stirring for 5 hours to obtain the nuclear seed microemulsion;

[0042] (4) First raise the temperature of the nuclear seed microemulsion prepared in step (3) ...

Embodiment 8

[0050] A kind of copolymer latex for negative electrode of lithium ion secondary battery, the latex particle contained in it has hard core soft shell structure, and average particle diameter is 100nm, by weight, described hard core is made of 80 parts of styrene, 15 parts of butyl A polymer formed by copolymerization of diene and 1 part of unsaturated carboxylic acid monomer. The glass transition temperature of the hard core is above 60°C. The soft shell is composed of 80 parts of butadiene, 20 parts of styrene, and 30 parts of vinyl A polymer formed by copolymerization of unsaturated monomers and 0.5 parts of nitrogen-sulfur-fluorine co-doped carbon nanotubes, wherein the hard core and soft shell account for 20% and 80% of the latex particle weight respectively.

[0051] The unsaturated carboxylic acid is acrylic acid.

[0052] The ethylenically unsaturated monomer is methyl acrylate.

[0053] In parts by weight, the hard core is a polymer formed by copolymerization of 100 p...

Embodiment 9

[0065] A kind of copolymer latex for negative electrode of lithium ion secondary battery, the latex particle contained in it has hard core soft shell structure, and average particle diameter is 100nm, and by weight, described hard core is made of 100 parts of styrene, 5 parts of butyl A polymer formed by copolymerization of diene and 5 parts of unsaturated carboxylic acid monomers. The glass transition temperature of the hard core is above 60°C. The soft shell is composed of 30 parts of butadiene, 70 parts of styrene, and 20 parts of vinyl A polymer formed by copolymerization of unsaturated monomers and 0.8 parts of 1-allyl-3-butylimidazolium tetrafluoroborate-modified carbon nanotubes, wherein the hard core and soft shell respectively account for 5% of the weight of latex particles , 95%.

[0066] The unsaturated carboxylic acid is methacrylic acid and maleic acid, and the mass ratio of the two is 1:1.

[0067] The ethylenically unsaturated monomer is octyl acrylate and itac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com