A kind of composite lithium metal negative electrode material and preparation method thereof

A metal anode and composite metal technology, applied in electrode manufacturing, electrode forming, battery electrodes, etc., can solve problems such as problems that are not well solved, shorten battery life, unstable anode structure, etc., to promote uniform deposition, The effect of improving cycle life and improving rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

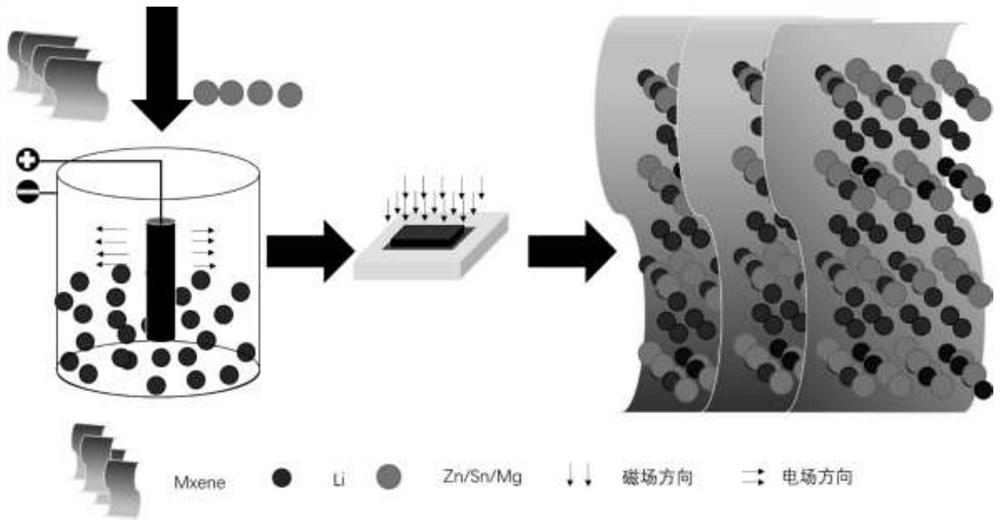

Method used

Image

Examples

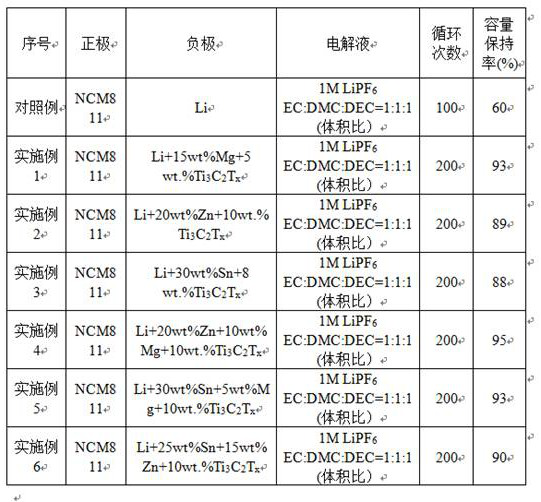

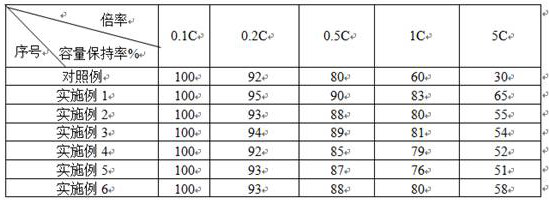

Embodiment 1

[0030] In an argon atmosphere, metal lithium and magnesium were added to the alloy melting furnace, wherein the amount of Mg was 15wt.%, and the melting temperature was 300 o C, apply an electric field of 0.5V to the heating furnace, keep for 1h; add 5 wt.% Ti 3 C 2 T x (T=O, F and other functional groups); After the Mxene material is added, continue to maintain the voltage for 1.5h until the entire molten mixture is evenly mixed; pour it into the mold and cool it to room temperature, and the mold as a whole is in a magnetic field with a strength of 0.1T In the magnetic field, after cooling to room temperature, take it out to make a composite lithium metal sheet; roll the composite lithium metal sheet to obtain a composite lithium metal strip with a thickness of 60 microns; slice it with a slicer to obtain a composite lithium metal sheet suitable for assembling batteries metal lithium anode. In an inert atmosphere glove box, use NCM811 as the electrode positive plate, and u...

Embodiment 2

[0032] In an argon atmosphere, metal lithium and zinc are added to the alloy melting furnace, wherein the amount of Zn is 20wt.%, and the melting temperature is 400 o C, apply an electric field of 1V to the heating furnace, keep for 0.5h; add 10 wt.% Ti 3 C 2 T x (T=O, F and other functional groups); After the Mxene material is added, continue to maintain the voltage for 2h until the entire molten mixture is mixed evenly; pour it into the mold and cool it to room temperature, and the mold as a whole is in a magnetic field with a magnetic field strength of 0.3T , take it out after cooling to room temperature, and then make a composite metal lithium plate; roll the composite metal lithium plate to obtain a composite metal lithium strip with a thickness of 100 microns; slice it with a slicer to obtain a composite metal sheet suitable for assembling batteries Lithium negative electrode. In an inert atmosphere glove box, use NCM811 as the electrode positive plate, and use 1M LiP...

Embodiment 3

[0034] In an argon atmosphere, metal lithium and tin were added to the alloy melting furnace, wherein the amount of Sn was 30wt.%, and the melting temperature was 550 o C, apply an electric field of 1.5V to the heating furnace, keep for 1h; add 8wt.% Ti 3 C 2 T x (T=O, F and other functional groups); After the Mxene material is added, continue to maintain the voltage for 2h until the entire molten mixture is mixed evenly; pour it into the mold and cool it to room temperature, and the mold as a whole is in a magnetic field with a magnetic field strength of 0.5T After cooling to room temperature, take it out to make a composite metal lithium plate; roll the composite metal lithium plate to obtain a composite metal lithium strip with a thickness of 120 microns; use a slicer to slice it to obtain a composite metal that is suitable for assembling batteries Lithium negative electrode. In an inert atmosphere glove box, use NCM811 as the electrode positive plate, and use 1M LiPF 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic flux density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com