A kind of polymetallic surface protective agent and its preparation method and application

A surface protectant, multi-metal technology, applied in the field of water circulation system, can solve the problem of high requirements for circulating water, and achieve the effect of preventing fine leakage, preventing scaling and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

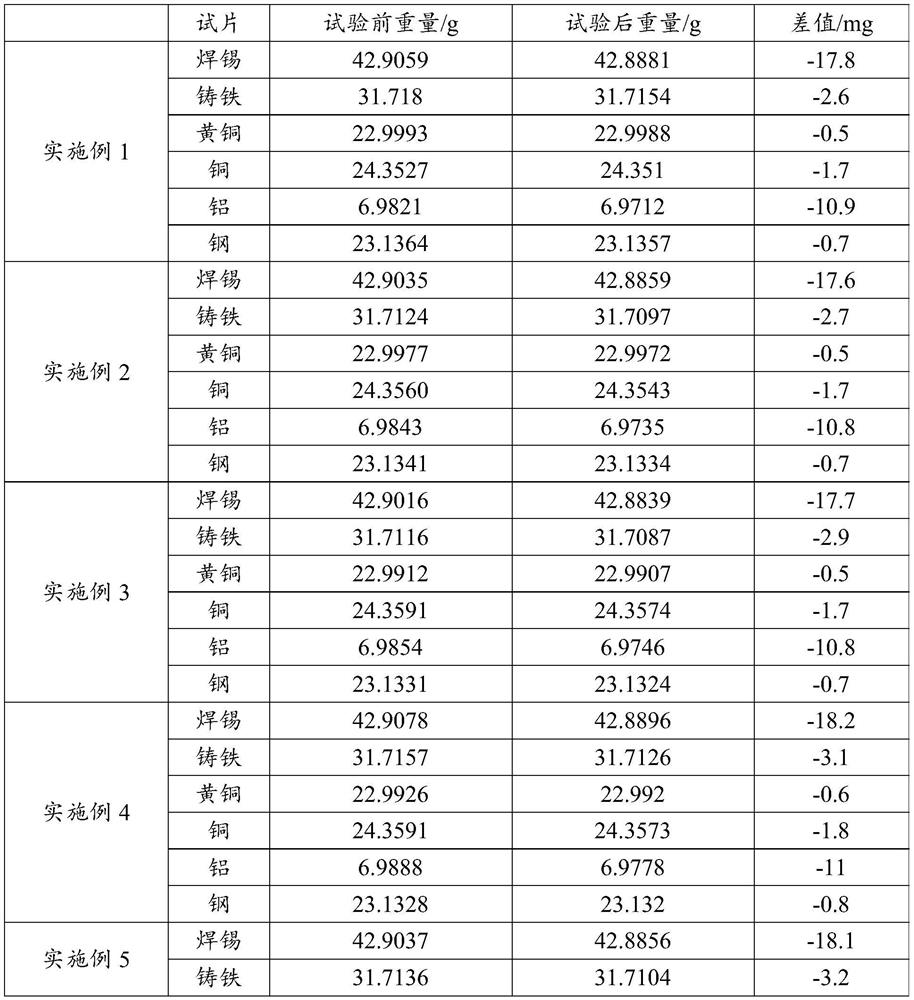

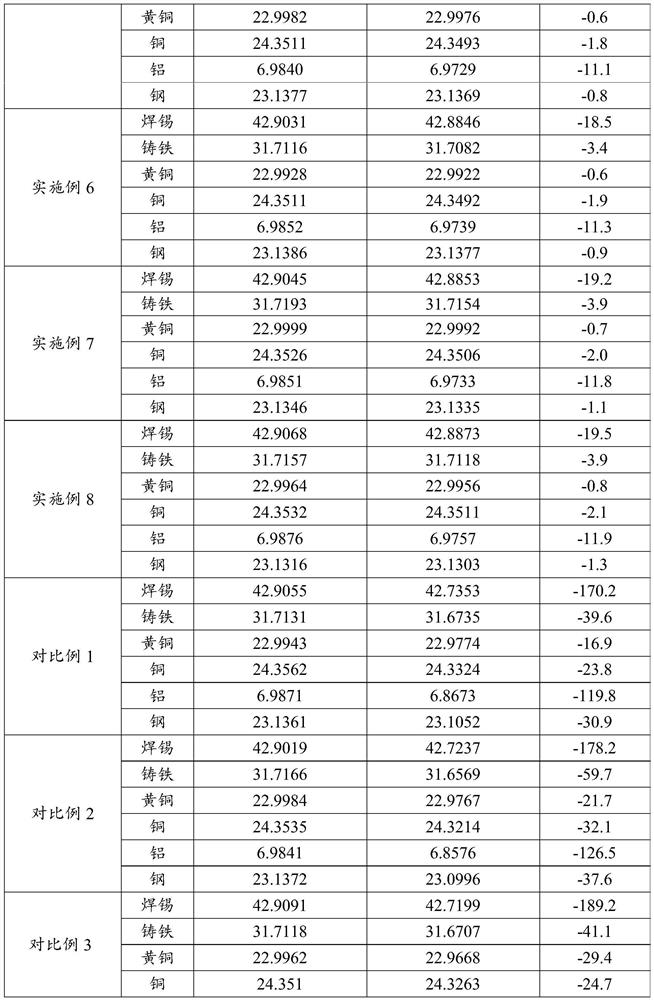

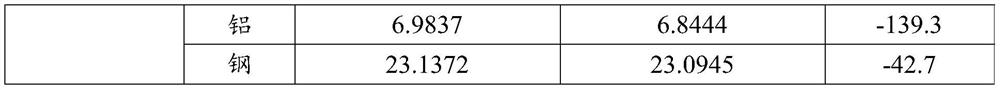

Examples

Embodiment 1

[0057] The present embodiment provides a kind of polymetallic surface protective agent, and its preparation method is as follows:

[0058] Preparation of film formers:

[0059] 5kg benzotriazole was dissolved in 5.5kg ethanol to obtain a mixed solution for subsequent use;

[0060] 25kg deionized water is added in the reactor and heated to 60 ℃ with stirring, then add 15kg undecanedioic acid, 10kg dodecanedioic acid, 12kg gluconic acid and 15kg benzoic acid, be warming up to 90 ℃ after adding, add 15kg of triethanolamine and 3kg of ethanolamine, and continue to stir for 0.5h: then add the above mixed solution, heat up to 110°C and stir for 1.5h, and then naturally drop to room temperature to obtain the film-forming agent for later use.

[0061] Preparation of occlusive agent:

[0062] After mixing 30kg of deionized water and 10kg of ammonium citrate uniformly, add 20kg of sebacic acid and 10kg of adipic acid at 80°C, then heat up to 88°C and stir for 30min; continue to add 15...

Embodiment 2

[0070] The present embodiment provides a kind of polymetallic surface protective agent, and its preparation method is as follows:

[0071] Preparation of film formers:

[0072] 10kg of benzotriazole was dissolved in 10kg of ethanol to obtain a mixed solution for subsequent use;

[0073] 20kg deionized water was added to the reactor and heated to 60°C with stirring, then 20kg of undecanedioic acid, 15kg of dodecanedioic acid, 15kg of gluconic acid and 6kg of benzoic acid were added, and the temperature was raised to 80°C after adding. 20kg of triethanolamine and 8kg of ethanolamine, and continue to stir for 1.5h: then add the above mixed solution, heat up to 120°C and stir for 2.5h, and then naturally drop to room temperature to obtain the film-forming agent for use.

[0074] Preparation of occlusive agent:

[0075]After mixing 20kg of deionized water and 15kg of ammonium citrate uniformly, add 25kg of sebacic acid and 15kg of adipic acid at 85°C, then heat up to 90°C and sti...

Embodiment 3

[0083] The present embodiment provides a kind of polymetallic surface protective agent, and its preparation method is as follows:

[0084] Preparation of film formers:

[0085] 8kg benzotriazole was dissolved in 7.2kg ethanol to obtain a mixed solution for subsequent use;

[0086] 16kg deionized water was added to the reactor and heated to 60°C with stirring, then 10kg of undecanedioic acid, 20kg of dodecanedioic acid, 8kg of gluconic acid and 10kg of benzoic acid were added, and the temperature was raised to 100°C after adding. 10kg of triethanolamine and 5kg of ethanolamine, and continue to stir for 1.0h: then add the above mixed solution, heat up to 130°C and stir for 2.0h, and then naturally drop to room temperature to obtain the film-forming agent for later use.

[0087] Preparation of occlusive agent:

[0088] After mixing 25kg of deionized water and 5kg of ammonium citrate uniformly, add 22kg of sebacic acid and 20kg of adipic acid at 75°C, then heat up to 85°C and st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com