Biomass pyrolysis-hydrothermal methanation poly-generation process with cross-seasonal energy storage function and device of process

A biomass pyrolysis and methanation technology, applied in the chemical industry, biofuels, inorganic chemistry, etc., can solve problems such as single product, difficult design and operation, and large storage volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

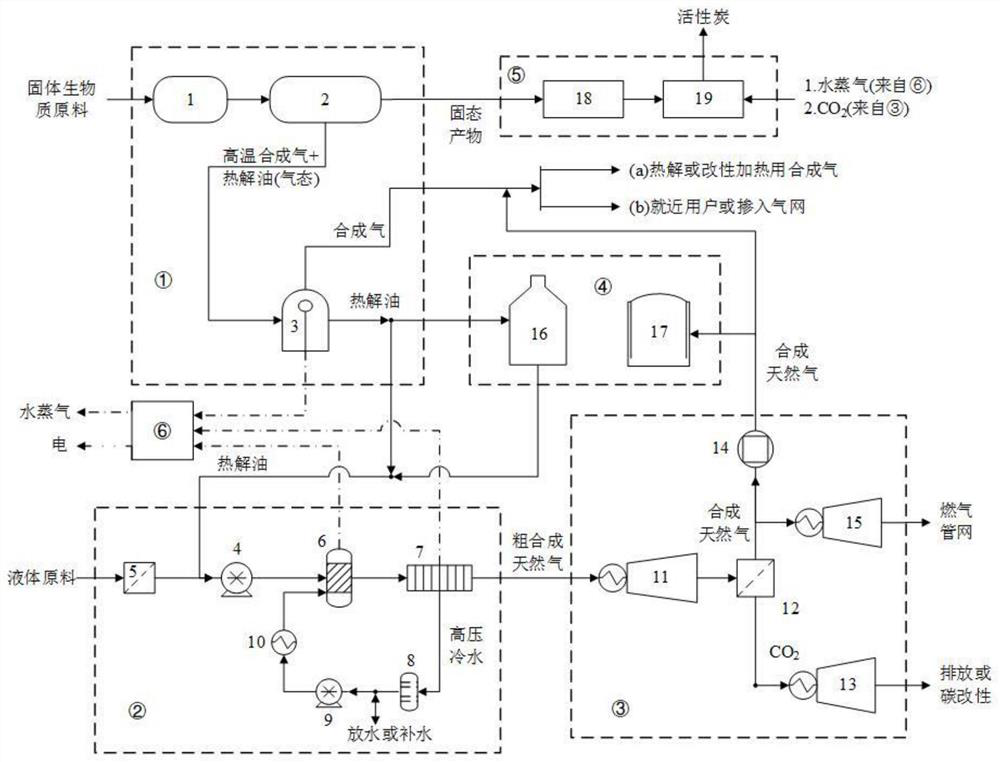

[0045] The furniture waste sawdust is used as the raw material, and the feed rate of the raw material is 3.6t / h. The lower calorific value is 16.4MJ / kg. The raw materials are subjected to rapid pyrolysis under normal pressure after being dried and preheated, and the pyrolysis temperature is 500°C. After the high-temperature mixture produced by pyrolysis undergoes gas-solid separation, the solid product coke and ash are passed through a biochar modification unit to first remove the ash and then combine with CO 2 CO from the separation unit 2 Activated carbon is obtained after modified treatment with water vapor generated in the waste heat recovery unit. The remaining high-temperature fluid products enter the condensation filter and separator, and are cooled to 30°C to achieve sufficient separation of product gas and pyrolysis oil. So far, the yields of gas-solid-liquid three-phase products produced by the pyrolysis reaction are about 7wt%, 18% and 75wt%, respectively. Among...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com