Method of preparing crystal aluminum chloride from circulation fluid bed fly ash

A technology of circulating fluidized bed and crystalline aluminum chloride, applied in aluminum chloride, aluminum halide and other directions, can solve problems such as limited source of raw materials, and achieve the effects of good product quality, wide range of raw materials and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

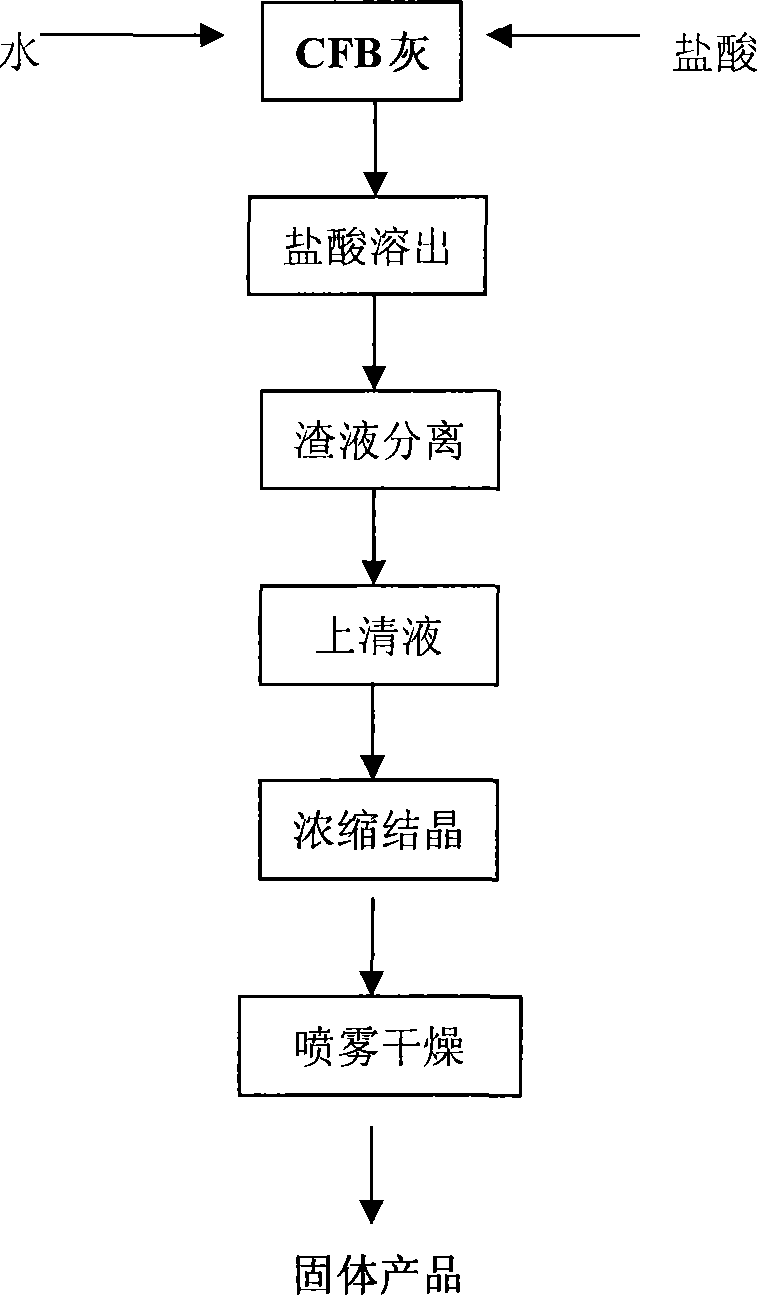

Image

Examples

Embodiment 1

[0021] Weigh 100 grams of circulating fluidized bed fly ash and place it in an acid-resistant reaction kettle, add 300 milliliters of hydrochloric acid with a mass concentration of 30%, and react for 2 hours under constant stirring at 100°C. Settling, generally using a settling tank, the slag liquid is separated in the settling tank to obtain the supernatant, and the aluminum chloride supernatant after the slag liquid separation is sent to the concentration tank for concentrated crystallization, and the sediment is leached slag, which is further washed , sedimentation, separation and discharge, in order to improve the settling performance, the flocculant polyacrylamide ammonium can be added, and the lotion from washing the filter residue is returned to the acid-resistant reaction kettle for reuse; the concentration tank is an enamel tank, which can be heated by steam, in order to speed up the concentration and crystallization The speed can be concentrated by negative pressure, ...

Embodiment 2

[0023] Weigh 100 grams of circulating fluidized bed fly ash, add 350 milliliters of hydrochloric acid with a mass concentration of 22.5%, and react for 2 hours under constant stirring at 100°C. , the slag liquid is separated in the settling tank to obtain the supernatant, and the aluminum chloride supernatant after the slag liquid separation is sent to the concentration tank for concentrated crystallization. , in order to improve the settling performance, the flocculant polyacrylamide ammonium can be added, and the lotion from washing the filter residue can be returned to the acid-resistant reaction kettle for reuse; the concentration tank is an enamel tank, which can be heated by steam. Concentrate under pressure, put the concentrated mother liquor into the buffer cooling tank, as the temperature drops, crystalline aluminum begins to precipitate, filter, and the filtrate enters the liquid storage tank for repeated use, and the obtained crystalline aluminum chloride is then spr...

Embodiment 3

[0025] Weigh 100 grams of circulating fluidized bed fly ash, add 400 milliliters of hydrochloric acid with a mass concentration of 15%, and react for 2 hours under constant stirring at 100°C. , the slag liquid is separated in the settling tank to obtain the supernatant, and the aluminum chloride supernatant after the slag liquid separation is sent to the concentration tank for concentrated crystallization. , in order to improve the settling performance, the flocculant polyacrylamide ammonium can be added, and the lotion from washing the filter residue can be returned to the acid-resistant reaction kettle for reuse; the concentration tank is an enamel tank, which can be heated by steam. Concentrate under pressure, put the concentrated mother liquor into the buffer cooling tank, as the temperature drops, crystalline aluminum begins to precipitate, filter, and the filtrate enters the liquid storage tank for repeated use, and the obtained crystalline aluminum chloride is then spray...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com