A continuous deformation composite profile and its preparation method

A composite material and deformation technology, which is applied in the field of composite materials, can solve problems such as relative movement is not smooth, reduces strength and winding characteristics, increases cost and weight, and achieves the effect of avoiding easy bending, resistance to bending damage, and reducing prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

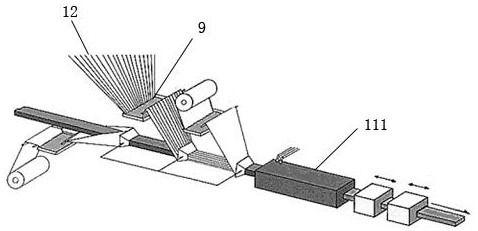

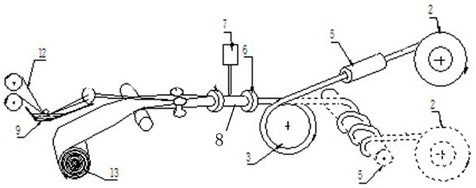

[0038] A preparation method of continuous deformation composite profile 2, such as figure 2 shown, including the following steps in sequence:

[0039] S1. Continuous longitudinal fibers 12 are impregnated with resin 9 to obtain a prepreg, wherein the raw material contains 50 parts of continuous longitudinal fibers 12 and 50 parts of resin 9, and the continuous longitudinal fibers 12 include a mixture of glass fibers and carbon fibers; metal 13 is passed through a guide The roller and the longitudinal mold are radially formed and welded by a continuous welding machine 7 to obtain a tube blank 8;

[0040] S2. Release the prepreg continuously into the tube blank 8 to obtain the material to be deformed. The linear speed at which the prepreg is brought into the tube blank 8 is welded with the metal 13 in S1 or extruded to form a tube The line speed of the blank 8 is equal, the prepreg fills the entrance of the tube blank 8, and part of the excess resin 9 in the prepreg is squeeze...

Embodiment 2

[0045] A preparation method of continuous deformation composite profile 2, such as figure 2 shown, including the following steps in sequence:

[0046] S1. Continuous longitudinal fibers 12 are impregnated with resin 9 to obtain a prepreg, wherein the raw material contains 30 parts of continuous longitudinal fibers 12 and 50 parts of resin 9, and the continuous longitudinal fibers 12 include a mixture of boron fibers, aramid fibers and silicon carbide fibers ; The metal strip 13 is radially formed by the guide roller and the longitudinal mold and welded by the continuous welding machine 7 to obtain the tube blank 8;

[0047] S2. Release the prepreg continuously into the tube blank 8 to obtain the material to be deformed. The linear speed at which the prepreg is brought into the tube blank 8 is welded with the metal 13 in S1 or extruded to form a tube The line speed of the blank 8 is equal, and the prepreg is not full, part of the excess resin 9 in the prepreg is left in the t...

Embodiment 3

[0053] A preparation method of continuous deformation composite profile 2, such as figure 2 shown, including the following steps in sequence:

[0054] S1. Continuous longitudinal fibers 12 are impregnated with resin 9 to obtain a prepreg, wherein the raw material contains 40 parts of continuous longitudinal fibers 12 and 50 parts of resin 9, and the continuous longitudinal fibers 12 include a mixture of silicon carbide fibers and basalt fibers; The material 13 is radially formed by guide rollers and longitudinal molds and welded by a continuous welding machine 7 to obtain a tube blank 8;

[0055] S2. Release the prepreg continuously into the tube blank 8 to obtain the material to be deformed. The linear speed at which the prepreg is brought into the tube blank 8 is welded with the metal 13 in S1 or extruded to form a tube The line speed of the blank 8 is equal, the prepreg fills the entrance of the tube blank 8, and part of the excess resin 9 in the prepreg is squeezed out; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com