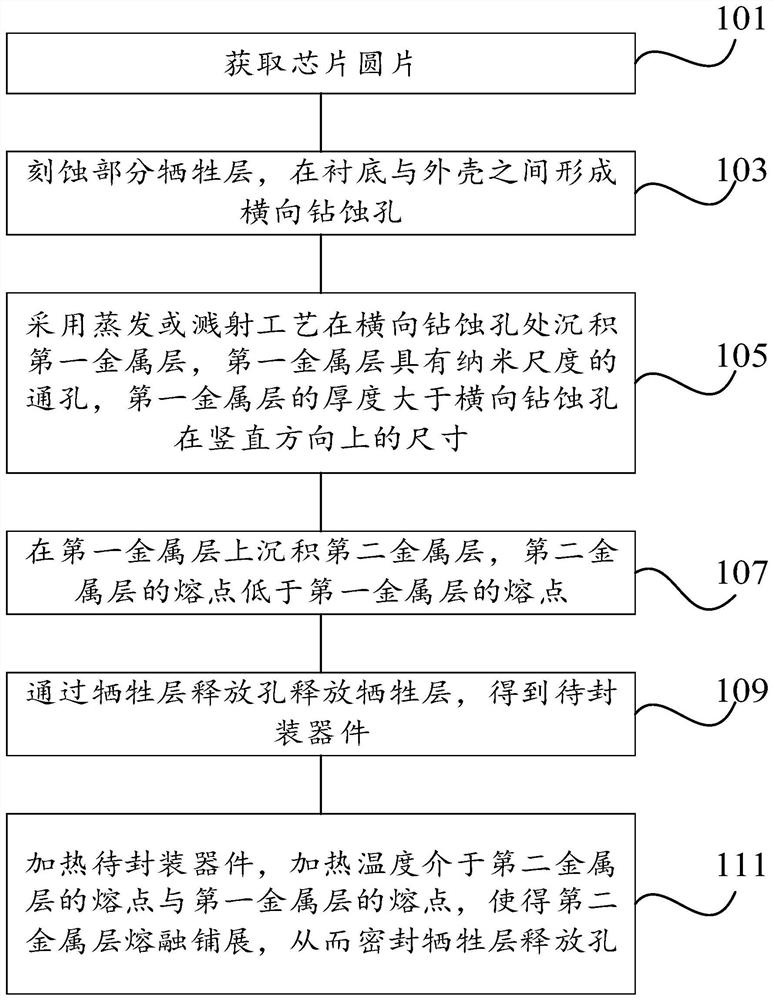

Wafer-level thin film packaging method and packaging device

A thin-film packaging and packaging method technology is applied in the field of wafer-level thin-film packaging methods and packaging devices, and can solve the problems of complex process process and high process temperature of micromechanical vacuum packaging technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

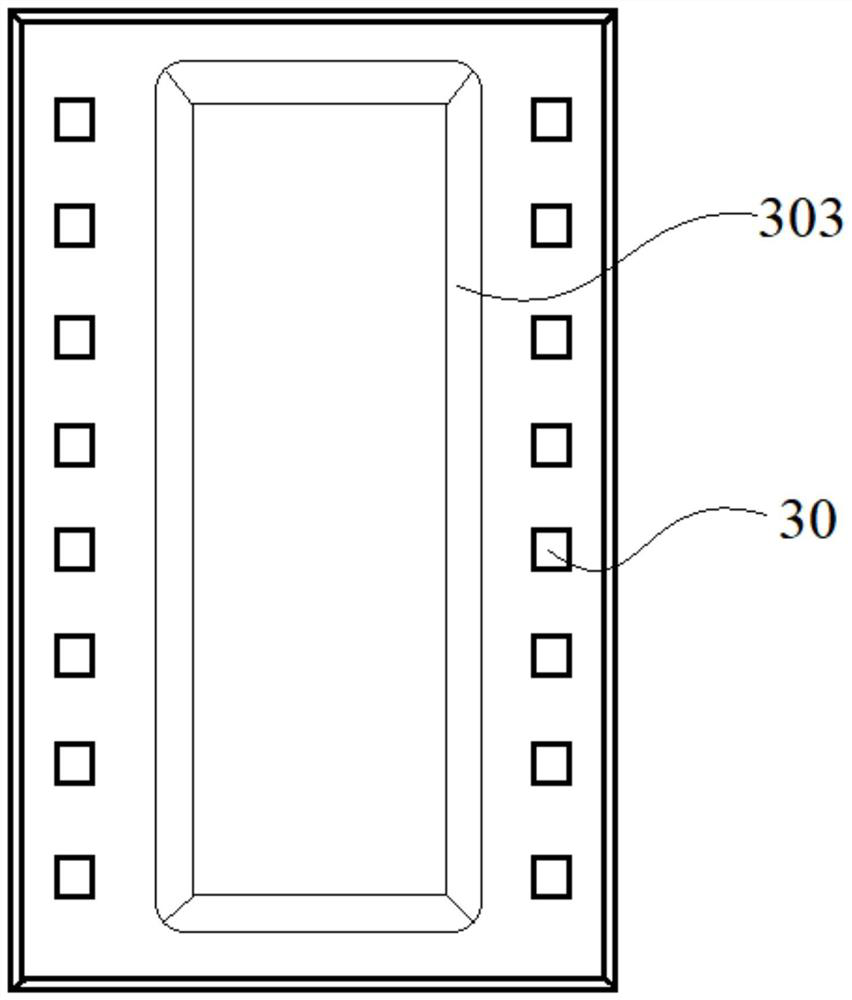

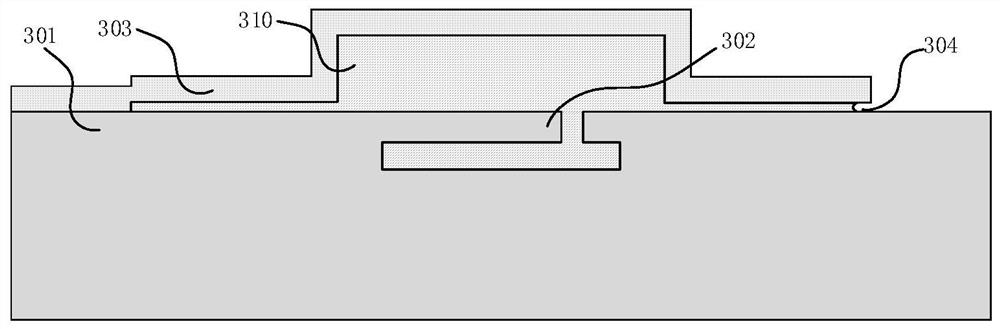

[0129] In this embodiment, the sacrificial layer 310 is made of thermally oxidized SiO 2 The shell 303 is made of LPCVD polysilicon, the sacrificial layer 310 is made of lateral drilled holes 304 by SiO2 (before metal) wet etching process, the first metal layer 306 is made of metal sputtering TiWu / Cu, and self-aligned to form nano-through The holes 307 and the second metal layer 308 are made of electroplated lead-free tin. The specific steps are:

[0130] Fabricating Micromechanical Structures 302: AS Figure 16 As shown, the micromechanical structure 302 is fabricated using a conventional bulk micromachining process.

[0131] Make double-layer sacrificial layer 310 structure: such as Figure 16 As shown, the double-layer sacrificial layer 310 structure adopts thermal oxidation SiO 2 fabrication, first using thermally oxidized SiO 2 Making the first sacrificial layer 311, using photolithography, SiO 2 The (pre-metal) wet etching process realizes patterning of the first s...

Embodiment 2

[0141] In this embodiment, the sacrificial layer 310 is made of LPCVD silicon dioxide, the shell 303 is made of micro-electroformed low-stress Ni, and the lateral drill hole 304 on the sacrificial layer 310 is made of SiO 2 (After metal) Wet etching process, the first metal layer 306 is made of metal evaporated Ni / Au, and self-aligned to form nano-vias 307, and the second metal layer 308 is made of metal sputtering Sn. The specific steps are:

[0142] Fabricating Micromechanical Structures 302: AS Figure 27 As shown, the micromechanical structure 302 is fabricated using a conventional bulk micromachining process.

[0143] Make double-layer sacrificial layer 310 structure: such as Figure 27 As shown, the double-layer sacrificial layer 310 structure is made of LPCVD silicon dioxide, firstly using LPCVD SiO 2 Make the first sacrificial layer 311, using photolithography / SiO 2 The (pre-metal) wet etching process realizes patterning of the first sacrificial layer 311 , and the...

Embodiment 3

[0152] In this embodiment, the sacrificial layer 310 structure is made of PECVD silicon dioxide, the shell 303 is made of PECVD polysilicon, the sacrificial layer 310 is made of SiO2 (before metal) wet etching process, and the first metal layer 306 is made of metal It is made by sputtering Ni / Au, and self-aligned to form the nanometer through hole 307, and the second metal layer 308 is made by metal sputtering In. The specific steps are:

[0153] Fabricating Micromechanical Structures 302: AS Figure 36 As shown, the micromechanical structure 302 is fabricated using a conventional bulk micromachining process.

[0154] Make double-layer sacrificial layer 310 structure: such as Figure 36 As shown, the double-layer sacrificial layer 310 structure is made of PECVD silicon dioxide, firstly using PECVD SiO 2 Make the first sacrificial layer 311, utilize the photolithography / SiO2 (before metal) wet etching process to realize the patterning of the first sacrificial layer 311, fina...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com