Catalyst based on solid carbon-rich fuel pyrolysis and preparation method thereof

A catalyst and carbon-rich technology, applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve the problems of complicated catalyst preparation process and energy waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] One aspect of the present invention provides a method for preparing a catalyst based on pyrolysis of solid carbon-rich fuel, comprising the steps of:

[0019] The solid carbon-rich fuel such as coal or biomass is pulverized and immersed in a mixed solution of manganese nitrate and copper nitrate or manganese nitrate and ferric nitrate. After the impregnation is completed, it is put into a settling furnace for pyrolysis to obtain a catalyst.

[0020] A large amount of tar will be generated in the direct pyrolysis process of biomass, and the generation of tar will affect the utilization of solid carbon. However, in the present application, by coating the catalyst with a good effect on the surface of the fuel, the deposition of a large amount of tar is minimized, which is beneficial to improving the catalytic performance of the catalyst.

[0021] Wherein the selected catalyst may be a mixed solution of manganese nitrate and copper nitrate or manganese nitrate and ferric ni...

Embodiment 1

[0039] 500 g of biomass prepared in advance was crushed into particles with a particle size of 1 mm, and left for 20 h.

[0040] The manganese nitrate solid and copper nitrate were sampled according to the molar ratio of 1:1, and the weighed two nitrates were mixed and dissolved in deionized water to prepare a mixed solution with a mass fraction of 50%.

[0041] Add the pre-treated biomass particles, and magnetically stir the nitrate mixed solution at 40°C for 4 hours. At the beginning of stirring, slowly add the precipitating agent sodium carbonate into the copper-manganese nitrate mixed solution, so that it can Sufficient precipitation is complete, and the precipitate is filtered.

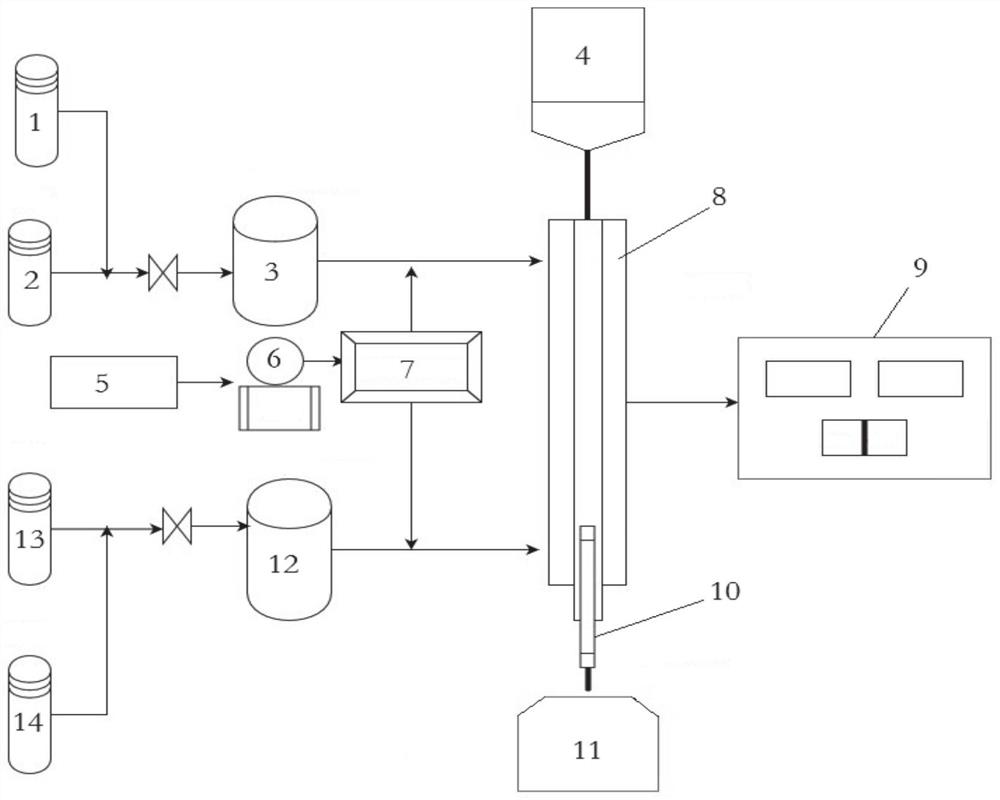

[0042] Such as figure 1 As shown, the pretreated biomass is put into the inside of the settling furnace 8 through the feeder 4;

[0043] After the nitrogen from the first nitrogen tank 1 and the oxygen from the first oxygen tank 2 are mixed in the primary air mixer 3, the primary wind is obtain...

Embodiment 2

[0048] 500 g of biomass was crushed into particles with a particle size of 1 mm and left for 24 h.

[0049] The solid manganese nitrate and ferric nitrate were taken out according to the molar ratio of 9:1, and the weighed two nitrates were mixed and dissolved in deionized water to prepare a mixed solution with a mass fraction of 50%.

[0050] At this time, put the pretreated biomass particles into the mixed solution, and let the nitrate mixed solution be magnetically stirred at 40°C for 4 hours. solution, so that it can fully precipitate completely, and filter the precipitate.

[0051] Put the obtained biomass fuel into the settling furnace for combustion, using the flash pyrolysis method, the primary air uses the gas mixed with oxygen and water vapor to blow the biomass powder into the settling furnace device, the volume fraction of oxygen is 5%, and the water vapor The volume fraction is 30%, and the others are nitrogen.

[0052] The secondary air enters the system throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com