Preparation method of nanofiltration composite membrane for softening water

A water softening and composite membrane technology, applied in the field of membrane separation, can solve the problems of insufficient separation efficiency and high rejection rate of monovalent ions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

[0024] The mass volume concentration (gram / 100 milliliter) is 0.06% iodomethane and polyethyleneimine co-dissolution in water, polyethyleneimine mass volume concentration (gram / 100 milliliter) is respectively 0.2%, 0.4%, 0.6%, 0.8%, 1.0%, co-dissolved at 30°C for 12 hours to obtain a quaternized polyethyleneimine aqueous solution. The mass volume concentration (gram / 100 milliliter) is that the cross-linking agent solution of 0.1% trimesic acid and 0.15 sodium lauryl sulfate is coated on the polyethersulfone ultrafiltration membrane surface, after removing excess solution, at 30 ℃ Dry in oven. Soak the surface of the dried membrane with quaternized polyethyleneimine aqueous solution, let it stand for 3 minutes, remove the excess solution, take it out after heat treatment at 90°C for 10 minutes, and then test the membrane after soaking in deionized water for 24 hours performance.

[0025] The test liquids are 500ppm saline solution and pure water respectively, and the desalina...

Embodiment 6-10

[0028] As in the above example, 0.02% methyl iodide and 0.6% polyethyleneimine were co-dissolved in water at a mass volume concentration (g / 100 ml), and 0, 4, 8, 12, and 16 were respectively co-dissolved at 25°C. hours, a quaternized polyethyleneimine aqueous solution was obtained. The surface of the polysulfone ultrafiltration membrane is coated with a cross-linking agent solution containing sodium dodecylsulfonate and trimesic acid, wherein the mass volume concentration of sodium dodecylsulfonate (g / 100 ml) is 0.15%, and The mass volume concentration (g / 100 ml) of triformic acid is 0.1%, respectively. Dry in an oven at 30°C for 10 minutes after removing excess solution. Coat the surface of the membrane with a quaternized polyethyleneimine aqueous solution, let it stand for 5 minutes, remove the excess solution, place it in a blast drying oven at 100°C for 10 minutes, take it out, and then soak it in deionized water for 24 hours Test membrane performance. .

[0029] The t...

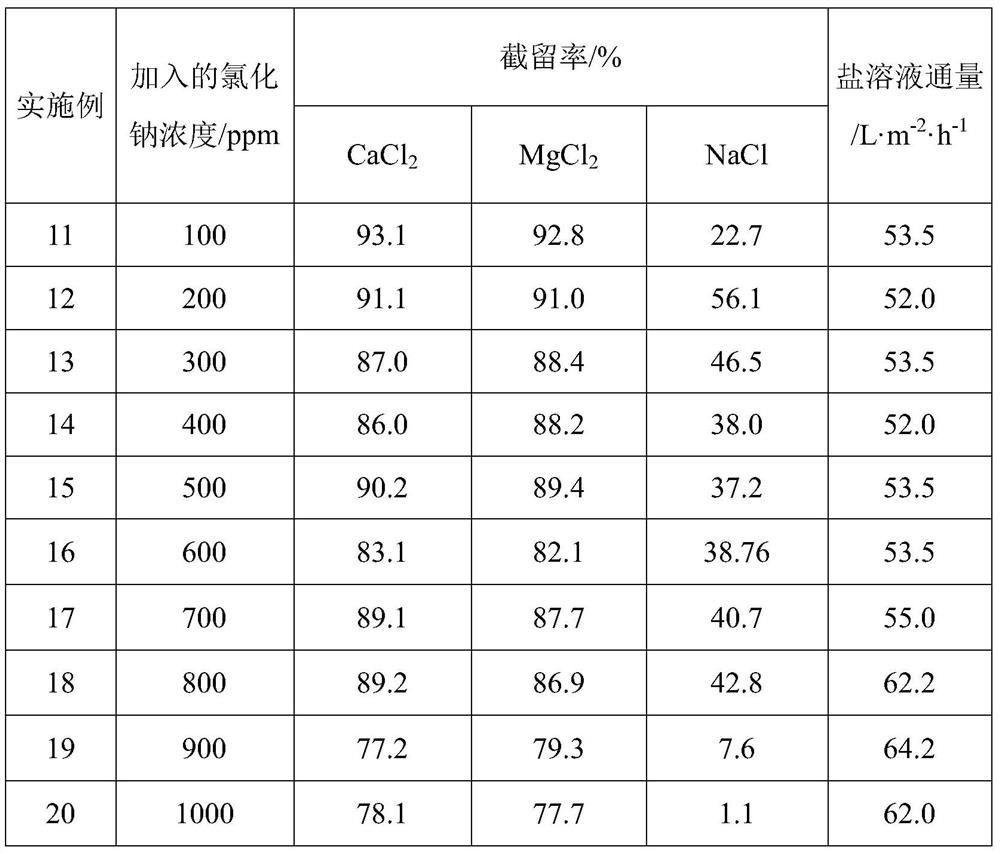

Embodiment 11-20

[0032] As in the above example, 0.02% methyl iodide and 0.4% polyethyleneimine were co-dissolved in water with a mass volume concentration (g / 100 ml) and co-dissolved at 25° C. for 10 hours to obtain quaternized polyethylene imine solution. The mass volume concentration (g / 100 ml) is 0.1% trimesic acid used as a cross-linking agent to infiltrate the surface of the polyethersulfone ultrafiltration membrane, and placed in an oven at 30° C. for 15 minutes. The quaternized polyethyleneimine aqueous solution was coated on the surface of the dried ultrafiltration membrane, heat-treated at 90°C for 10 minutes, and then soaked in deionized water for 24 hours to test the membrane performance.

[0033] The test solution is a mixed salt solution of 100ppm magnesium chloride solution and 100ppm calcium chloride solution and sodium chloride solution of different concentrations, and the membrane performance is tested at an operating temperature of 25°C and an operating pressure of 0.2MPa. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com