Carotenoid-containing emulsion and preparation method, application and beverage thereof

A carotene and emulsion technology, which is applied in the directions of medical preparations containing active ingredients, applications, and preparations for skin care, etc., can solve the problems of easy delamination of emulsions, inability to use end products, and long transportation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

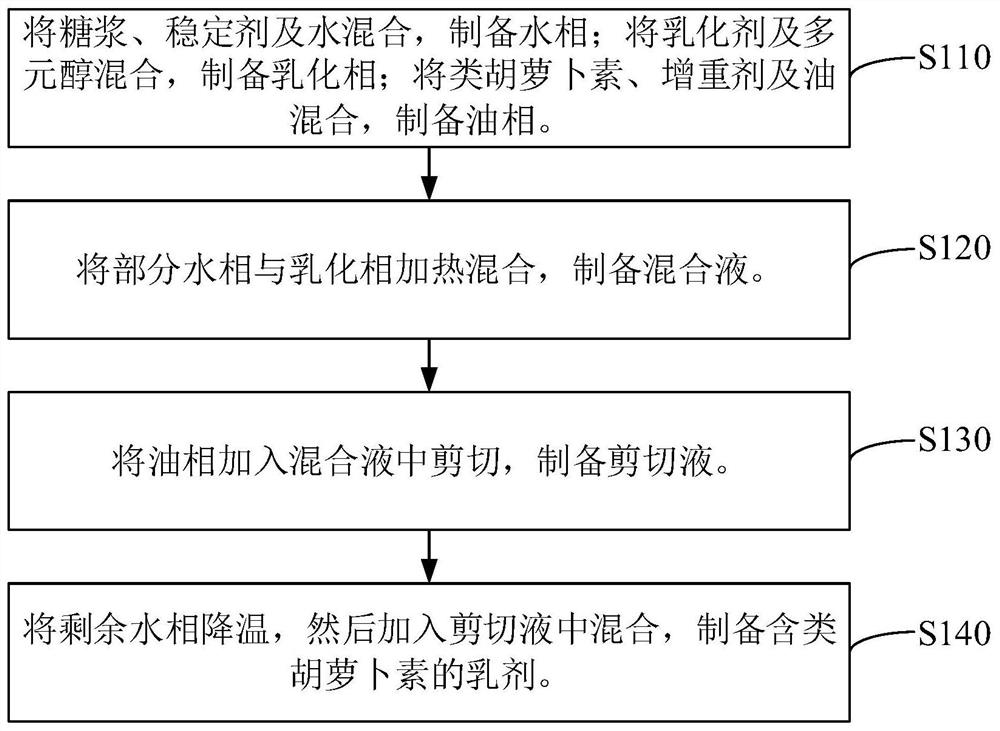

[0033] Specifically, see figure 1 , the preparation method of the carotenoid-containing emulsion of the present embodiment comprises the following steps:

[0034] Step S110: mixing syrup, stabilizer and water to prepare a water phase; mixing an emulsifier and a polyol to prepare an emulsified phase; mixing carotenoids, a weighting agent and an oily solvent to prepare an oil phase.

[0035] Specifically, in the carotenoid-containing emulsion, the mass percentage of the water phase is 10% to 35%, the mass percentage of the emulsifier is 3% to 6%, the mass percentage of the polyol is 34% to 86%, and the oil phase The mass percentage is 1% to 25%.

[0036] Wherein, the syrup is at least one selected from high fructose corn syrup, fructose syrup and white granulated sugar. The Brix of syrup is 20Brix~75Brix. In one embodiment, the syrup has a Brix of 35 Brix, 55 Brix or 70 Brix.

[0037] The stabilizer is at least one selected from gum arabic, guar gum, gellan gum, konjac gum, ...

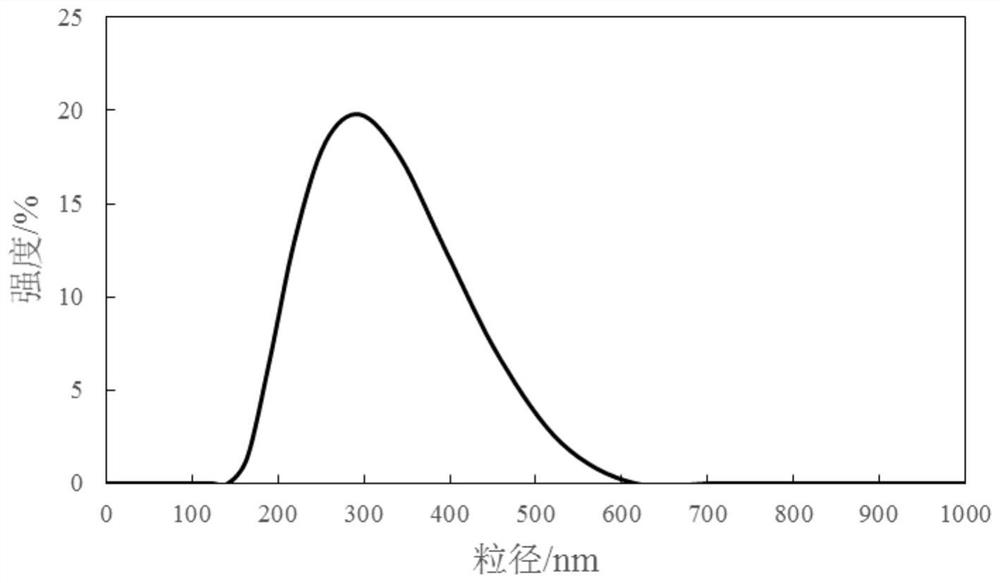

Embodiment 1

[0066] The preparation process of the carotenoid-containing emulsion of the present embodiment is as follows:

[0067] (1) 55Brix syrup solution is packed in the stirring tank, add gellan gum, stir and dissolve evenly at 60 ℃ of temperature, prepare water phase, in water phase, the mass percentage of syrup is 10%, the mass percentage of gellan gum is 1%, the balance is water.

[0068] (2) Put decaglycerol capric acid glyceride, propylene glycol and sorbitol into a stirring tank, stir at 60° C. to dissolve completely, and prepare an emulsified phase.

[0069] (3) After weighing palm oil and rosin glyceride and heating to 105° C., add β-carotene and continue to stir until a transparent solution is formed to prepare an oil phase. In the oil phase, the mass percentage of β-carotene is 1%. The mass percentage of rosin glyceride is 57%, and the mass percentage of palm oil is 42%.

[0070] (4) Add 1 / 5 of the mass of the aqueous phase prepared in step (1) to the emulsified phase in ...

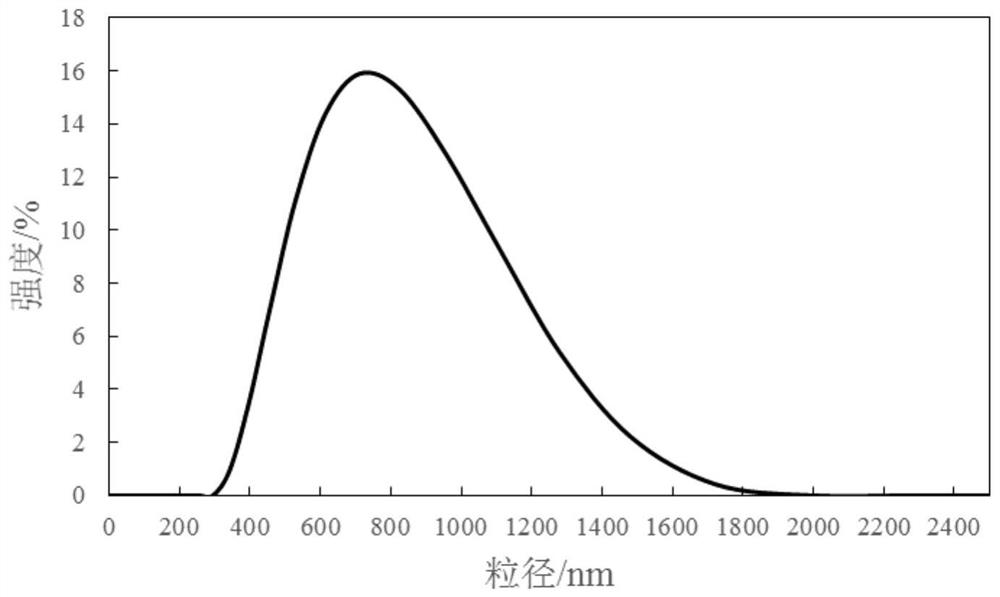

Embodiment 2

[0074] The preparation process of the carotenoid-containing emulsion of the present embodiment is as follows:

[0075] (1) 70Brix syrup solution is put into a stirring tank, add guar gum, stir and dissolve evenly at a temperature of 70° C., and prepare an aqueous phase. In the aqueous phase, the mass percentage of syrup is 15%, and the mass percentage of gellan gum 0.5%, the balance is water.

[0076] (2) Put soap bark extract, lecithin, propylene glycol and sorbitol into a stirring tank, stir at 70° C. to dissolve completely, and prepare an emulsified phase.

[0077] (3) Weigh palm oil, sucrose acetate isobutyrate and rosin glyceride and heat it to 105°C, then add β-carotene and keep stirring until a clear solution is formed to prepare the oil phase. In the oil phase, β-carotene The mass percentage of sucrose acetate isobutyrate and rosin glyceride is 45%, and the mass percentage of palm oil is 54.9%.

[0078] (4) Add 1 / 3 of the mass of the water phase prepared in step (1) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com