Preparation method of carbon quantum dot composite material taking terbium-doped sunflower stem pith as carbon source

A technology of carbon quantum dots and composite materials, applied in the field of nano-luminescent material preparation, can solve problems such as lack of application, and achieve the effects of good biocompatibility, small size and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

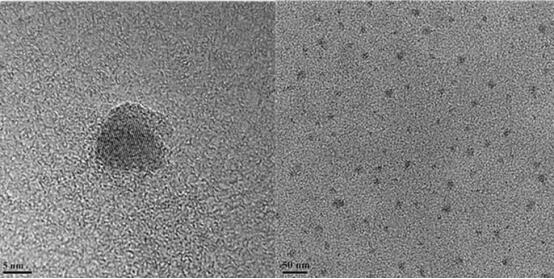

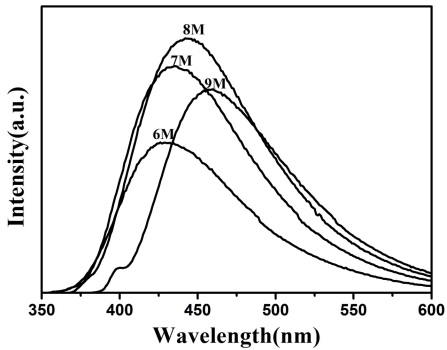

Embodiment 1

[0013] (1) Preparation of sunflower stem pith powder: Remove the cortex and xylem from sunflower stems, which are agricultural production wastes, to obtain spongy sunflower stem pith, cut them into pieces, put them in a beaker, add deionized water, and heat in a water bath to boil After cooling to 24±2°C for 20 minutes, wash it repeatedly with deionized water three times, place it in an oven with a temperature of 100±2°C and dry it at a constant temperature for 4 hours, after cooling to 24±2°C, take it out and place it in a high-speed pulverizer After crushing, pass the obtained powder through a 200-mesh sieve to obtain sunflower stem pith powder with a particle size of less than 75 μm. (2) Preparation of carbon quantum dots: In a reaction kettle containing 50ml polytetrafluoroethylene liner, add raw materials according to the following proportions, sunflower stem pith: 2g, sulfuric acid: 6M 30ml, put in an oven at a temperature of 180±2°C React at a medium constant temperatur...

Embodiment 2

[0015] (1) Preparation of sunflower stem pith powder: Remove the cortex and xylem from sunflower stems, which are agricultural production wastes, to obtain spongy sunflower stem pith, cut them into pieces, put them in a beaker, add deionized water, and heat in a water bath to boil After cooling to 24±2°C for 20 minutes, wash it repeatedly with deionized water three times, place it in an oven with a temperature of 100±2°C and dry it at a constant temperature for 4 hours, after cooling to 24±2°C, take it out and place it in a high-speed pulverizer After crushing, pass the obtained powder through a 200-mesh sieve to obtain sunflower stem pith powder with a particle size of less than 75 μm. (2) Preparation of carbon quantum dots: In a reaction kettle containing 50ml polytetrafluoroethylene liner, add raw materials according to the following ratio, sunflower stem pith: 3g, sulfuric acid: 7M 30ml, put in an oven at a temperature of 180±2°C React at a medium constant temperature for ...

Embodiment 3

[0017](1) Preparation of sunflower stem pith powder: Remove the cortex and xylem from sunflower stems, which are agricultural production wastes, to obtain spongy sunflower stem pith, cut them into pieces, put them in a beaker, add deionized water, and heat in a water bath to boil After cooling to 24±2°C for 20 minutes, wash it repeatedly with deionized water three times, place it in an oven with a temperature of 100±2°C and dry it at a constant temperature for 4 hours, after cooling to 24±2°C, take it out and place it in a high-speed pulverizer After crushing, pass the obtained powder through a 200-mesh sieve to obtain sunflower stem pith powder with a particle size of less than 75 μm. (2) Preparation of carbon quantum dots: In a reaction kettle containing 50ml of polytetrafluoroethylene liner, add raw materials according to the following proportions, sunflower stem pith: 4g, sulfuric acid: 8M 30ml, put in an oven at a temperature of 180±2°C React at medium constant temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com