Method for preparing sulfur-phosphorus co-doped carbon quantum dots by adopting buckwheat shell as carbon source

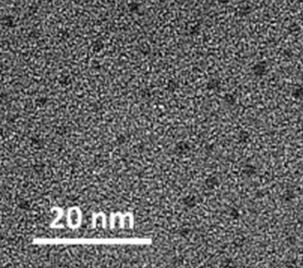

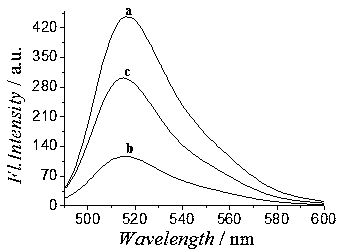

A technology of carbon quantum dots, carbon source sulfur phosphorus, applied in chemical instruments and methods, nanotechnology for materials and surface science, nanotechnology, etc. Low quantum yield, unclear luminescence mechanism, etc., to achieve the effect of improved fluorescence performance, uniform size and good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (1) Buckwheat husk powder pretreatment: In the reactor, add 3.0mol / L hydrochloric acid solution: 80mL, potassium periodate: 6g, dissolve, then add buckwheat husk powder: 14g, soak at room temperature for 8h, and then boil After cooling for 30 minutes, wash with deionized water until neutral, separate solid and liquid, then wash with deionized water until neutral, and dry to obtain pretreated buckwheat husk powder;

[0021] (2) Preparation of crude sulfur-phosphorus co-doped carbon quantum dots: Add 1-ethyl-2,3-dimethylimidazolium hexafluorophosphorus salt in a reaction kettle with a polytetrafluoroethylene liner: 66g, pretreated buckwheat husk powder: 26g, thioacetamide: 8g, stir evenly, cover the airtight cover, place in a constant temperature box, keep the temperature at 120±2°C, and react for 25h to obtain a brown viscous transparent liquid, which is Crude sulfur and phosphorus co-doped carbon quantum dots;

[0022] (3) Preparation of sulfur and phosphorus co-doped ...

Embodiment 2

[0024] (1) Buckwheat husk powder pretreatment: In the reactor, add 3.0mol / L hydrochloric acid solution: 79mL, potassium periodate: 5g, dissolve, then add buckwheat husk powder: 16g, soak at room temperature for 8h, and then boil After cooling for 30 minutes, wash with deionized water until neutral, separate solid and liquid, then wash with deionized water until neutral, and dry to obtain pretreated buckwheat husk powder;

[0025] (2) Preparation of crude sulfur-phosphorus co-doped carbon quantum dots: Add 1-ethyl-2,3-dimethylimidazolium hexafluorophosphorus salt in a reaction kettle with a polytetrafluoroethylene liner: 67g, pretreated buckwheat husk powder: 27g, thioacetamide: 6g, stir evenly, cover the airtight cover, place in a constant temperature box, keep the temperature at 120±2°C, and react for 26h to obtain a brown viscous transparent liquid, which is Crude sulfur and phosphorus co-doped carbon quantum dots;

[0026] (3) Preparation of sulfur and phosphorus co-doped ...

Embodiment 3

[0028] (1) Buckwheat husk powder pretreatment: In the reactor, add 3.0mol / L hydrochloric acid solution: 78mL, potassium periodate: 7g, dissolve, then add buckwheat husk powder: 13g, soak at room temperature for 8h, and then boil After cooling for 30 minutes, wash with deionized water until neutral, separate solid and liquid, then wash with deionized water until neutral, and dry to obtain pretreated buckwheat husk powder;

[0029] (2) Preparation of crude sulfur-phosphorus co-doped carbon quantum dots: Add 1-ethyl-2,3-dimethylimidazolium hexafluorophosphorus salt in a reaction kettle with a polytetrafluoroethylene liner: 66g, pretreated buckwheat husk powder: 24g, thioacetamide: 10g, stir evenly, cover the airtight cover, place in a constant temperature box, keep the temperature at 120±2°C, and react for 24h to obtain a brown viscous transparent liquid, which is Crude sulfur and phosphorus co-doped carbon quantum dots;

[0030] (3) Preparation of sulfur and phosphorus co-doped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com