High-strength weather-resistant modified silane sealant and preparation process thereof

A weather-resistant, high-strength technology, applied in the direction of adhesives, adhesive types, polymer adhesive additives, etc., can solve the problems of easily polluted building materials, low tear strength, poor recoatability, etc., to avoid surface cracks, Low viscosity, effect of suppressing surface cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

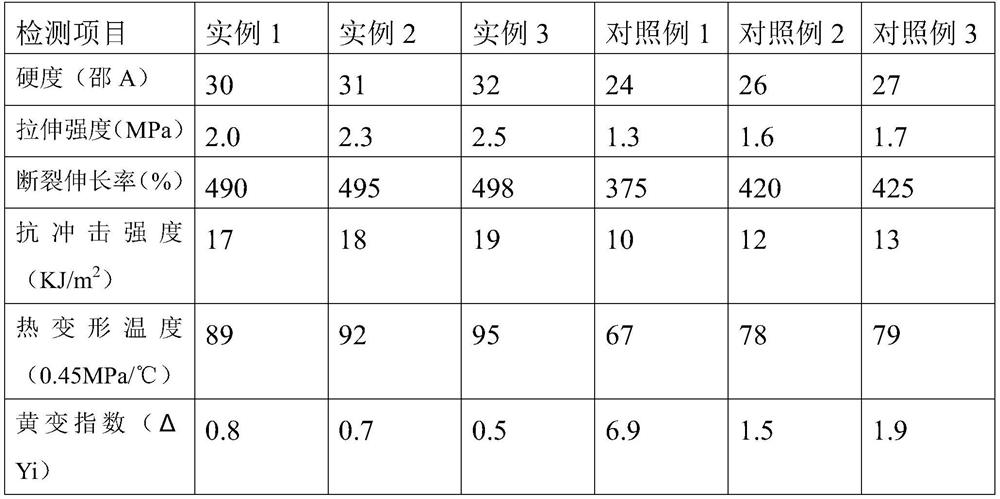

Examples

example 1

[0065] Collect papermaking black liquor and filter to obtain the filtrate, mix the filtrate with 30% tartaric acid solution in a volume ratio of 1:2, put it into the reactor, heat until boiling, then cool naturally to 50°C, and continue to pour into the reactor Add hydrochloric acid with a concentration of 1mol / L to adjust the pH to 2.5, keep the temperature for 2 hours, and then centrifuge to obtain lignin precipitate; mix the lignin precipitate obtained above with acetone and deionized water at a mass ratio of 1:9:1 and load it into In the beaker, stir with a magnetic stirrer at a speed of 200r / min to obtain a lignin solution, drop the lignin solution into deionized water along the beaker wall to obtain a suspension, put the suspension in a rotary evaporator, Rotate and concentrate to recover acetone, then freeze-dry the concentrated solution for 20 hours to obtain a dried product, and set aside; mix salicylaldehyde, acetic anhydride and sodium acetate in a molar ratio of 1:3...

example 2

[0067] Collect the papermaking black liquor and filter to obtain the filtrate, mix the filtrate with the tartaric acid solution with a mass fraction of 30% in a volume ratio of 1:2, put it into the reactor, heat it until boiling, then cool it naturally to 55°C, and continue to pour it into the reactor Add hydrochloric acid with a concentration of 1mol / L to adjust the pH to 2.8, keep the temperature for 3 hours and then centrifuge to obtain the lignin precipitate; mix the lignin precipitate obtained above with acetone and deionized water at a mass ratio of 1:9:1 and put it into In the beaker, stir with a magnetic stirrer at a speed of 250r / min to obtain a lignin solution, drop the lignin solution into deionized water along the beaker wall to obtain a suspension, put the suspension in a rotary evaporator, Rotate and concentrate to recover acetone, and then freeze-dry the concentrated solution for 22 hours to obtain a dry product for use; mix salicylaldehyde, acetic anhydride and ...

example 3

[0069] Collect the papermaking black liquor and filter to obtain the filtrate, mix the filtrate with the tartaric acid solution with a mass fraction of 30% in a volume ratio of 1:2, put it into the reactor, heat it until it boils, then cool it naturally to 60°C, and continue to pour it into the reactor Add hydrochloric acid with a concentration of 1mol / L to adjust the pH to 3.0, keep the temperature for 4 hours and then centrifuge to obtain the lignin precipitate; mix the lignin precipitate obtained above with acetone and deionized water at a mass ratio of 1:9:1 and put it into In the beaker, stir with a magnetic stirrer at a speed of 300r / min to obtain a lignin solution, drop the lignin solution into deionized water along the beaker wall to obtain a suspension, put the suspension in a rotary evaporator, Rotate and concentrate to recover acetone, then freeze-dry the concentrated solution for 24 hours to obtain a dry product, and set aside; mix salicylaldehyde, acetic anhydride ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com