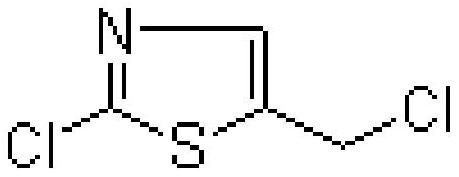

Clean and environment-friendly production process of 2-chloro-5-chloromethylthiazole

A chloromethylthiazole, clean and environmentally friendly technology, applied in the direction of organic chemistry, etc., can solve the problems of alkali consumption, high yield and purity, no guidance scheme is given, and achieves the effect of solving environmental pollution, high yield and purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

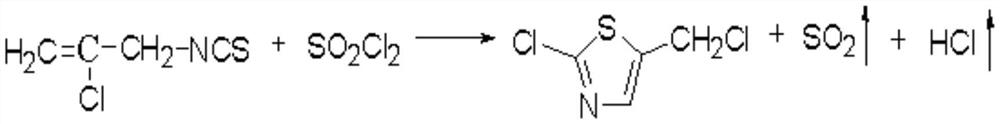

[0022] Embodiment 1: the production technology (production method) of the clean and environment-friendly 2-chloro-5-chloromethylthiazole of the present invention comprises the following processing steps: 1. 1mol sodium thiocyanate is dissolved in 160g in 1000ml four-necked bottle In water, the mass ratio of sodium thiocyanate to water is 1:1.975, add 2,3-dichloropropene dropwise in a four-necked bottle at 70°C, and the feeding moles of 2,3-dichloropropene and sodium thiocyanate The ratio is 1.1:1, the dropping time is 6 hours, after the dropping is completed, the heat preservation reaction is 6 hours, and the obtained material is washed and layered with water, and the intermediate product 2-chloropropenyl isothiocyanate is obtained by distillation, which is set aside; ② in a 1000ml four-necked bottle Dissolve the intermediate product 2-chloropropenyl isothiocyanate in 300g of dichloroethane, the mass ratio of 2-chloropropenyl isothiocyanate to dichloroethane is 1:2.36, at 50°C ...

Embodiment 2

[0023] Embodiment 2: the production technique of the clean and environment-friendly 2-chloro-5-chloromethylthiazole of the present invention comprises following processing steps: 1. in 1000ml four-necked bottle, 1mol sodium thiocyanate is dissolved in 178g water, thiocyanate The mass ratio of sodium thiocyanate to water is 1:2.2, and 2,3-dichloropropene is added dropwise in a four-necked bottle at 90°C, and the molar ratio of 2,3-dichloropropene to sodium thiocyanate is 1.2: 1. The dropping time is 4.5 hours. After the dropping is completed, keep warm for 5 hours. The obtained material is washed with water, stratified, and distilled to obtain the intermediate product 2-chloropropenyl isothiocyanate, which is set aside; The product 2-chloropropenyl isothiocyanate is dissolved in 350g of dichloroethane, the mass ratio of 2-chloropropenyl isothiocyanate and dichloroethane is 1:2.8, at 55°C in four ports 0.97mol sulfonyl chloride was added dropwise in the bottle for the first time...

Embodiment 3

[0024] Embodiment 3: the production technology of the clean and environment-friendly 2-chloro-5-chloromethylthiazole of the present invention comprises following processing steps: 1. in 1000ml four-necked bottle, 1mol sodium thiocyanate is dissolved in 145g water, thiocyanate The mass ratio of sodium thiocyanate to water is 1:1.8, and 2,3-dichloropropene is added dropwise in a four-necked bottle at 100°C, and the molar ratio of 2,3-dichloropropene to sodium thiocyanate is 1.2: 1. The dropping time is 8 hours. After the dropping is completed, keep warm for 6 hours. The obtained material is washed with water, stratified, and distilled to obtain the intermediate product 2-chloropropenyl isothiocyanate, which is set aside; ② Put the intermediate product in a 1000ml four-necked bottle Dissolve 2-chloropropenyl isothiocyanate in 399g of dichloroethane, the mass ratio of 2-chloropropenyl isothiocyanate to dichloroethane is 1:3, in a four-necked bottle at 60°C 1mol sulfonyl chloride w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com