Multi-deformation casting grinding machining equipment and grinding method thereof

A grinding and casting technology, which is applied in the field of multi-deformation casting grinding and processing equipment, can solve the problems of harsh working environment of iron castings, difficulty in ensuring the cleanliness of castings in the working environment, and rising operating costs, so as to meet the needs of the production environment and process , the effect of long-term battery life, and the effect of maintaining the quality of work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

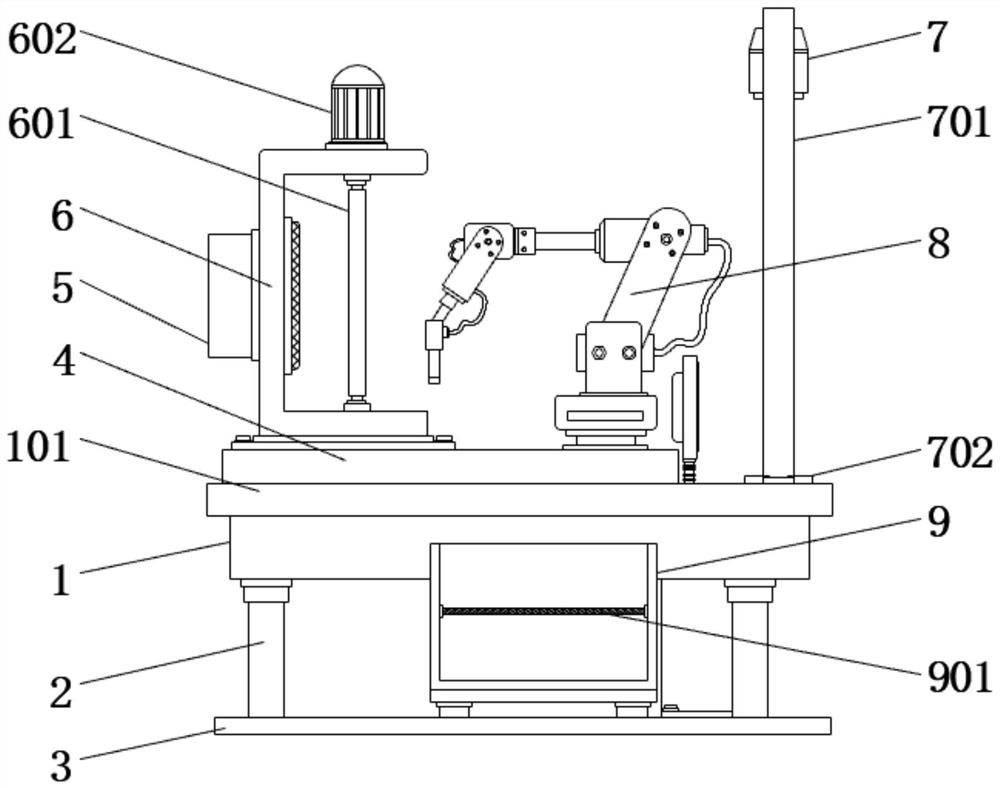

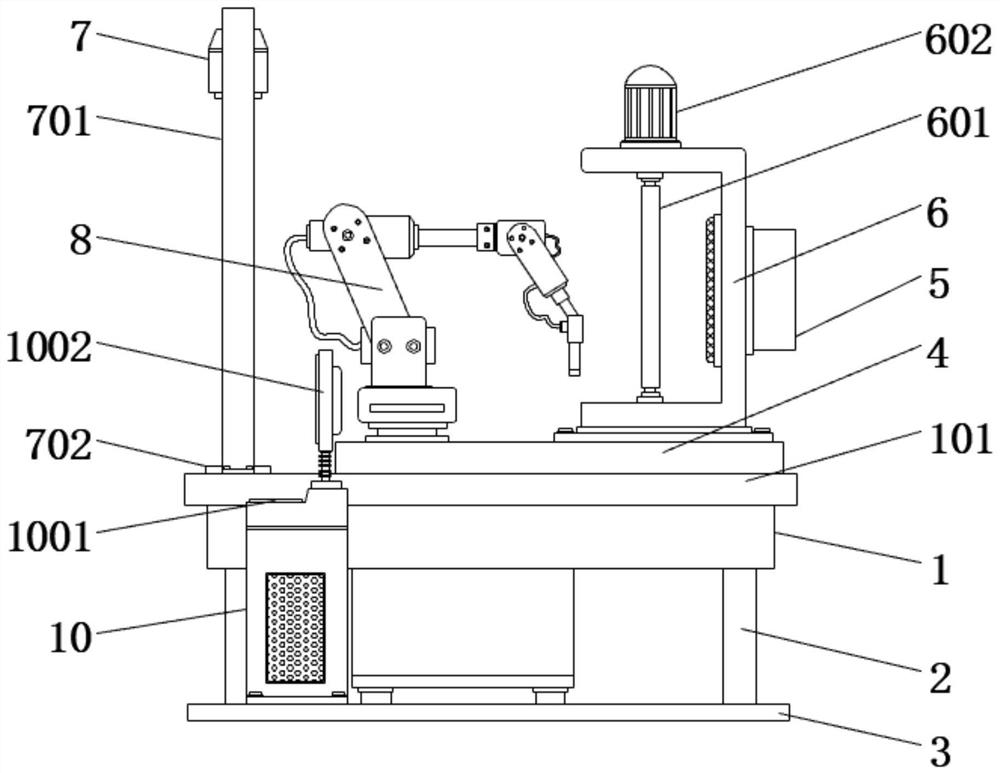

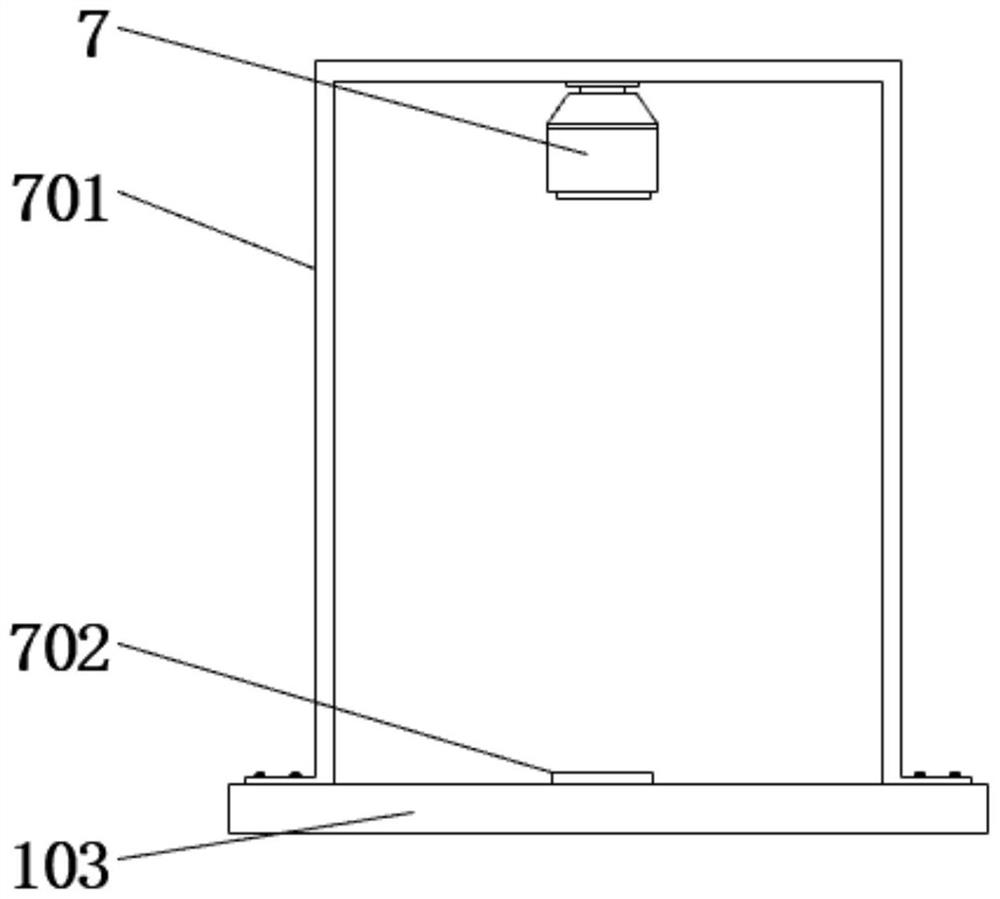

[0024] see Figure 1-3 , an embodiment provided by the present invention: a multi-deformation casting grinding processing equipment and grinding method thereof, including a base 1, a supporting substrate 3, an automatic grabbing mechanism 8, a pickling tank 9 and a manipulation mechanism 10, through the following step:

[0025] Step 1: the top of the support base plate 3 is installed with the base 1 carrying the operating mechanism through the support column 2, the top of the base base 1 is installed with an operation table 101 for grinding and processing the casting, and the support base 3 on the rear side of the base 1 is installed There is a control mechanism 10, a control host is installed inside the control mechanism 10, and a control panel 1001 and a display 1002 are respectively provided on the top of the control mechanism 10, and the staff can control and program the operation information of the equipment through the control panel 1001 and the display 1002, Ensure tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com