Self-lubricating wear-resistant flux-cored wire containing nickel-coated graphite component and welding method thereof

A technology of nickel-coated graphite and flux-cored welding wire is applied in the field of self-lubricating wear-resistant flux-cored welding wire containing nickel-coated graphite and its welding, which can solve the burning loss of graphite phase and alloy elements, waste air environment of alloy elements, and affect the surfacing welding. Layer wear resistance and other issues, to achieve the effects of less welding fume, improved deposition rate, and stable arc

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

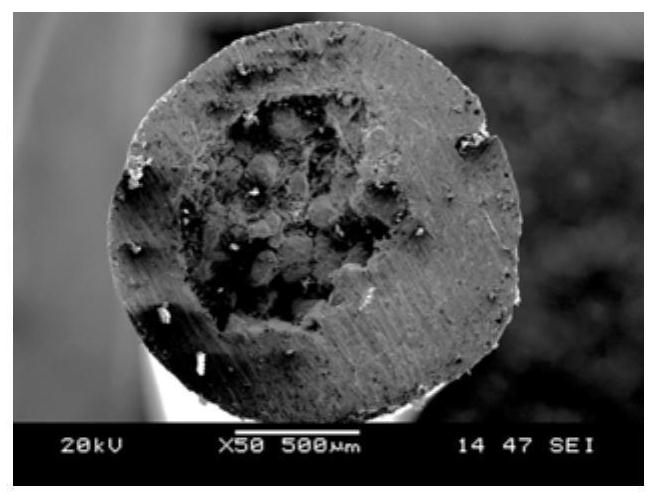

Image

Examples

preparation example Construction

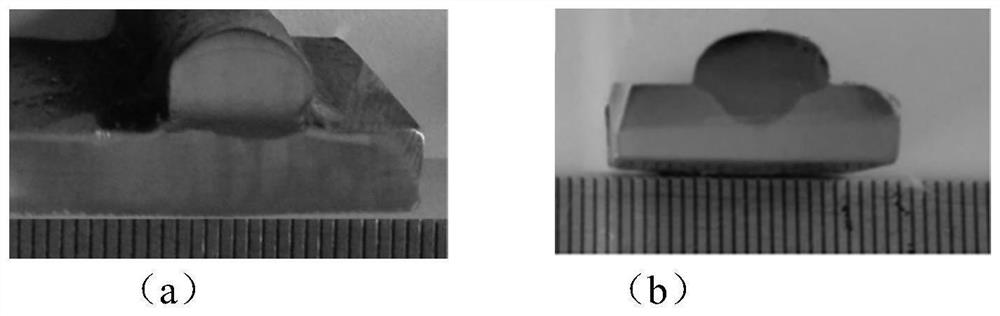

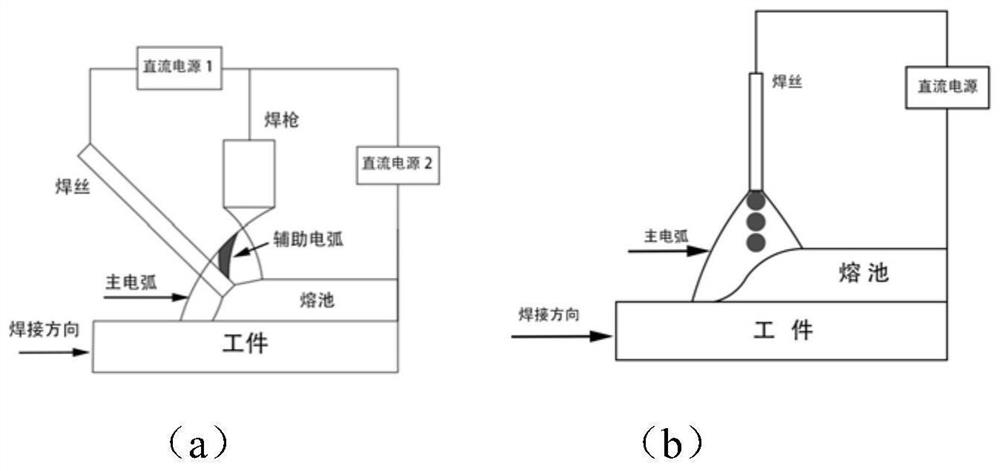

[0034] 2. Preparation of surfacing layer:

[0035] Example:

[0036] Using the self-built double constant current source arc hot wire GTAW welding system, on the 6mm thick Q235 steel plate, the self-designed flux-cored wear-resistant welding wire containing nickel-coated graphite is used for surfacing welding. Its process parameters are: welding voltage: 22-26V; main arc current: 240A; auxiliary arc current: 120A; wire feeding speed: 2.4m / min; welding speed: 3.5mm / s ; Distance between tungsten electrode and workpiece: 7-8mm; distance between tungsten electrode and welding wire: 2-3mm; shielding gas flow rate: 15L / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com