Polyamide resin composition, molded body thereof, and method for manufacturing laser-welded body

A technology of polyamide resin and laser welding, which is applied in the direction of chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve the problems of insufficient laser transmittance and difficulty in obtaining laser welding, and achieve high durability Effects of heat resistance, high mechanical strength, and good welding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

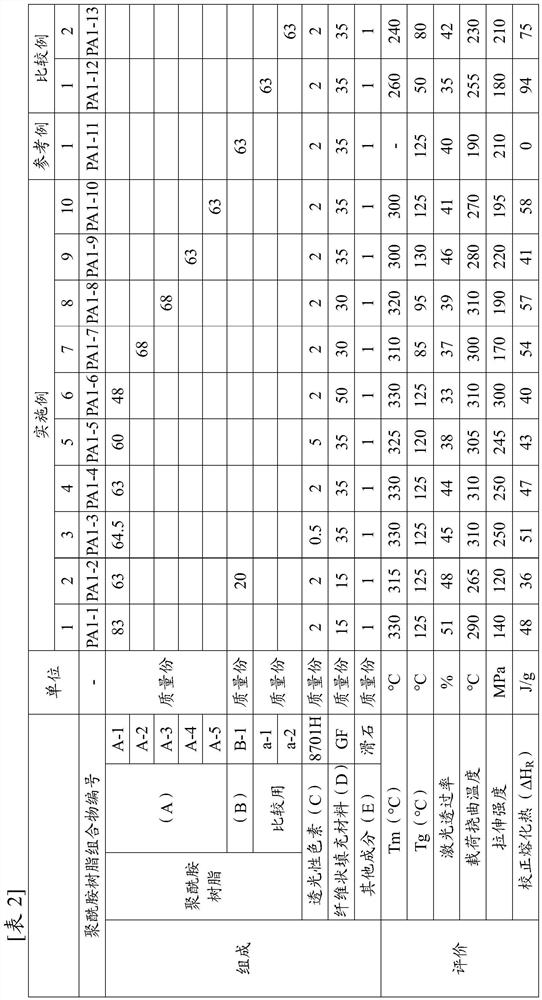

[0178] Hereinafter, the present invention will be described with reference to examples. The scope of the present invention is not limitedly interpreted by the Examples.

[0179] 1. Preparation of materials

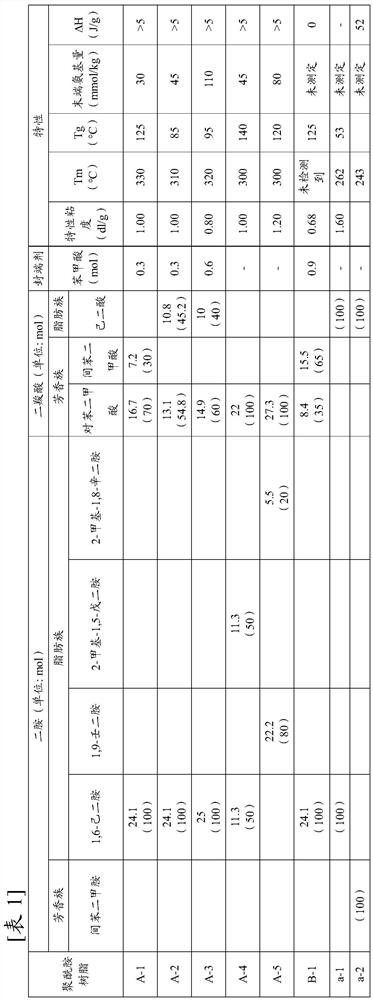

[0180] (1) Polyamide resin (A)

[0181]

[0182] 2800g (24.1 moles) of 1,6-hexanediamine, 2774g (16.7 moles) of terephthalic acid, 1196g (7.2 moles) of isophthalic acid, 36.6g (0.30 moles) of benzoic acid, and 5.7 grams of sodium hypophosphite monohydrate g and 545 g of distilled water were placed in an autoclave with an inner capacity of 13.6 L, and nitrogen substitution was performed. Stirring was started from 190°C, and the internal temperature was raised to 250°C over 3 hours. At this time, the internal pressure of the autoclave was increased to 3.03 MPa. The reaction was continued for 1 hour in this state, and after that, the air was released from the spray nozzle installed in the lower part of the autoclave to extract the low-order condensate. Then, the low-gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com