Slag modification reducer and preparation method thereof, and method for Fe recovery with slag waste heat

A waste heat recovery and reducing agent technology, which is applied in the field of slag waste heat recovery iron and slag modified reducing agent, can solve the problems of large land occupation, loss of metal elements, waste of resources, etc., to reduce processing energy consumption and promote rapid response , Improve the effect of iron recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

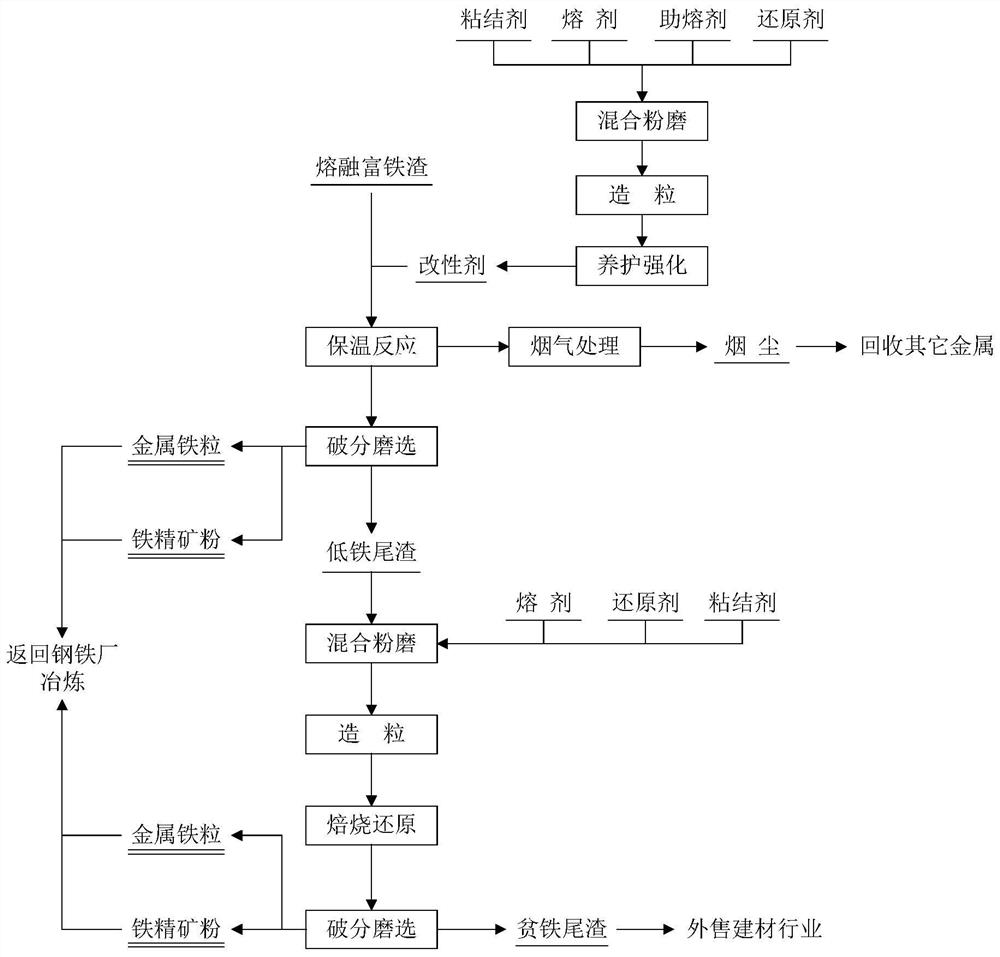

Method used

Image

Examples

preparation example Construction

[0033] The preparation method of the slag modified reducing agent according to the embodiment of the second aspect of the present invention includes the following steps: a. Combining 5-24 parts by weight of reducing agent, 6-12 parts by weight of binder, and 0-3 parts by weight The activators are separately ground into powder, then uniformly mixed, and granulated once to obtain granules with a particle size of 5-10mm. The activator is selected from at least one of industrial soda ash, sodium chloride, potassium carbonate or fluorite B. Mix 100 parts by weight of flux, 2-6 parts by weight of binder and 0-10 parts by weight of flux, and grind them into powder; c. Add the granules obtained in step a to the granulator As the inner core of the slag modified reducing agent, the powder obtained in the step b is coated on the inner core and subjected to secondary granulation to obtain spherical particles with a core-shell structure with a particle diameter of 15-25 mm. In the method of...

Embodiment 1

[0041] 1. Preparation of slag modified reducing agent

[0042] After 100 parts by weight of quicklime, 6 parts by weight of anthracite coal powder, 10 parts by weight of cement and 3 parts by weight of fluorite are uniformly mixed, they are ball milled to a particle size of less than 0.1 mm to obtain modified reducing agent powder. Then, pelletizing is carried out in the disc pelletizer, and a small amount of water can be added to promote the pelletizing process. After the pellet size reaches 15-25mm, it will be discharged to the conveyor belt. The modified reducing agent pellets on the conveyor belt are transported to the curing silo, and water vapor is introduced into the warehouse to promote the rapid increase of the mechanical strength of the modified reducing agent pellets, and the slag modified reducing agent used in production is cured by curing.

[0043] 2. Method for recovering iron from slag waste heat

[0044] While the molten copper slag discharged from the copper smelt...

Embodiment 2

[0048] 100 parts by weight of limestone, 21 parts by weight of coke powder, 16 parts by weight of clay powder, and 8 parts by weight of fluorite are mixed uniformly, and then ball milled to a particle size of less than 0.1 mm to obtain modified reducing agent powder. Then, the modified reducing agent powder is mixed with a small amount of water to form a semi-wet material, and then pelletized in a ball press with a particle size of 25mm. The manufactured pellets are discharged on the conveyor belt and then transported to the curing bin. Air is introduced into the bin to promote the rapid increase of the mechanical strength of the modified reducing agent pellets, and the slag modified reducing agent used in production is cured by curing.

[0049] 2. Method for recovering iron from slag waste heat

[0050] When the molten nickel slag discharged from the nickel smelting furnace at a temperature of 1350~1420℃ is poured into the hot stuffy slag pit, the molten slag modifying reducing ag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com