Neodymium-iron-boron magnet and method for regulating and controlling grain size and grain size distribution of coarse grain layer of neodymium-iron-boron magnet

A technology of grain size and particle size distribution, used in the manufacture of magnetic objects, magnetic materials, inductors/transformers/magnets, etc. The effect of narrow diameter distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

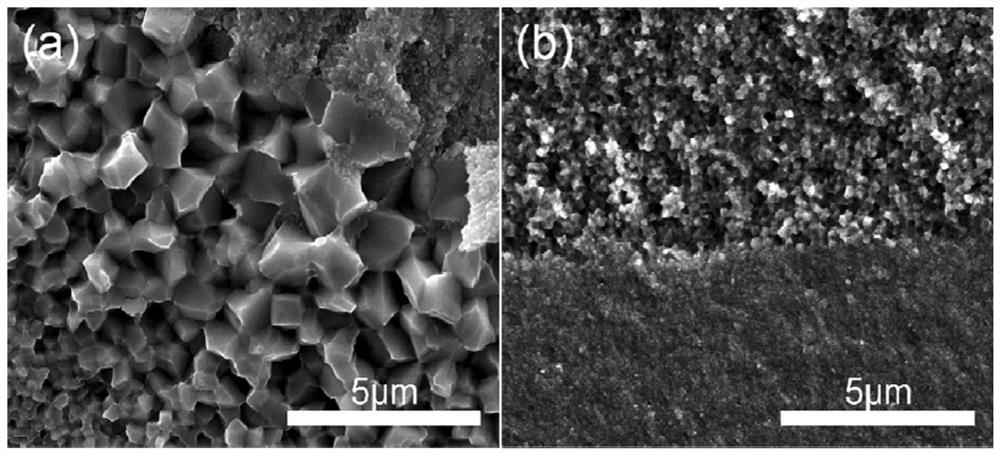

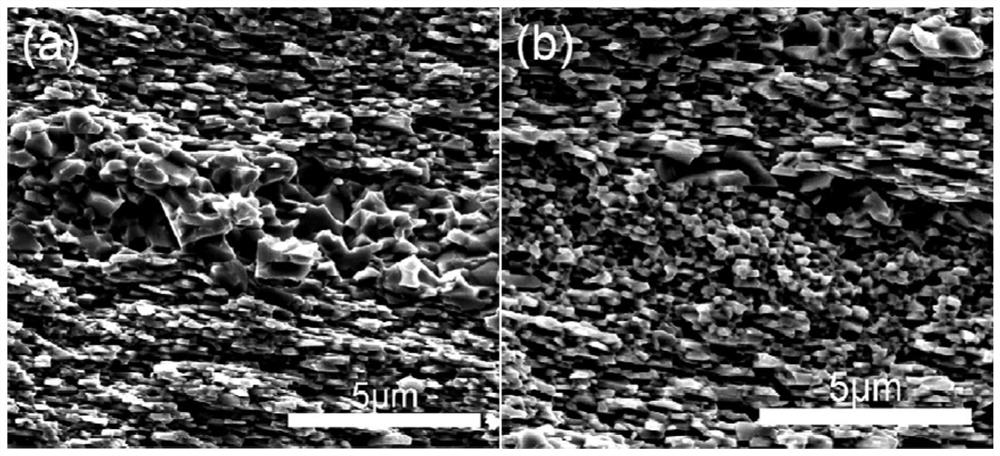

Image

Examples

Embodiment 1

[0037](1) Concentrated nitric acid solution and deionized water or ethanol are prepared into a dilute nitric acid solution with a pH of 1.3, weigh 35g of NdFeB quick-quenching powder, slowly pour it into the dilute nitric acid solution and keep stirring for pickling, pickling The washing time is 1 minute, and the oxygen content of the quick-quenching powder after pickling drops by 892ppm.

[0038] (2) Wash the acid-washed magnetic powder repeatedly with deionized water and ethanol for several times, and then put the washed magnetic powder into a drying oven for drying at a drying temperature of 70°C-80°C.

[0039] (3) Put the dried magnetic powder into a hot pressing mold M1 with an inner diameter of 16.3 mm. Put the heat press mold M1 into the vacuum induction heat press and evacuate to 5×10 -2 Pa, turn on the induction heating system for heating, and at the same time turn on the hydraulic system, and adjust the pressure acting on the mold M1 to 200MPa; when the heating temp...

Embodiment 2

[0052] According to the method of embodiment 1, the pickling time in the step (1) is changed to 5min, and the oxygen content of the quick-quenching powder drops by 862ppm after pickling. The rest of the steps remain unchanged to obtain isotropic / anisotropic NdFeB magnets. It is observed that the grains of the coarse-grained layer of the obtained magnet are the same as in Example 1, and the grains are obviously refined and the grain size distribution is narrowed.

Embodiment 3

[0054] According to the method for embodiment 1, the pH of the dilute nitric acid solution is 1 in the step (1), and the oxygen content of the quick-quenching powder drops by 732ppm after pickling. The rest of the steps remain unchanged to obtain isotropic / anisotropic NdFeB magnets. It is observed that the grains of the coarse-grained layer of the obtained magnet are the same as in Example 1, and the grains are obviously refined and the grain size distribution is narrowed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com