Electric wire capable of resisting high temperature of 1000 DEG C and preparation method thereof

A technology of high temperature resistance and wire, applied in the field of power cables, can solve the problems of low heat resistance, easy damage, affecting safety, reliability, etc., to prevent aging and catalytic effect, reduce load-bearing tension and vibration, and ensure service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

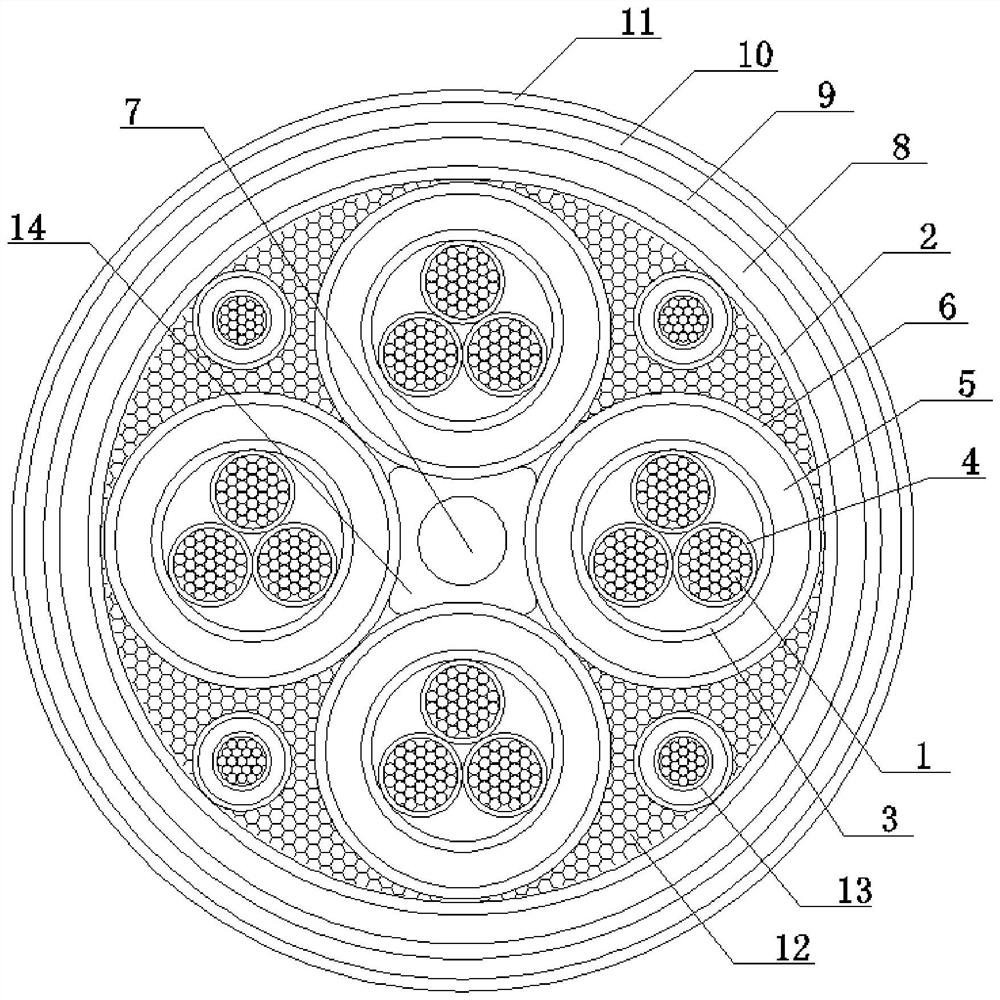

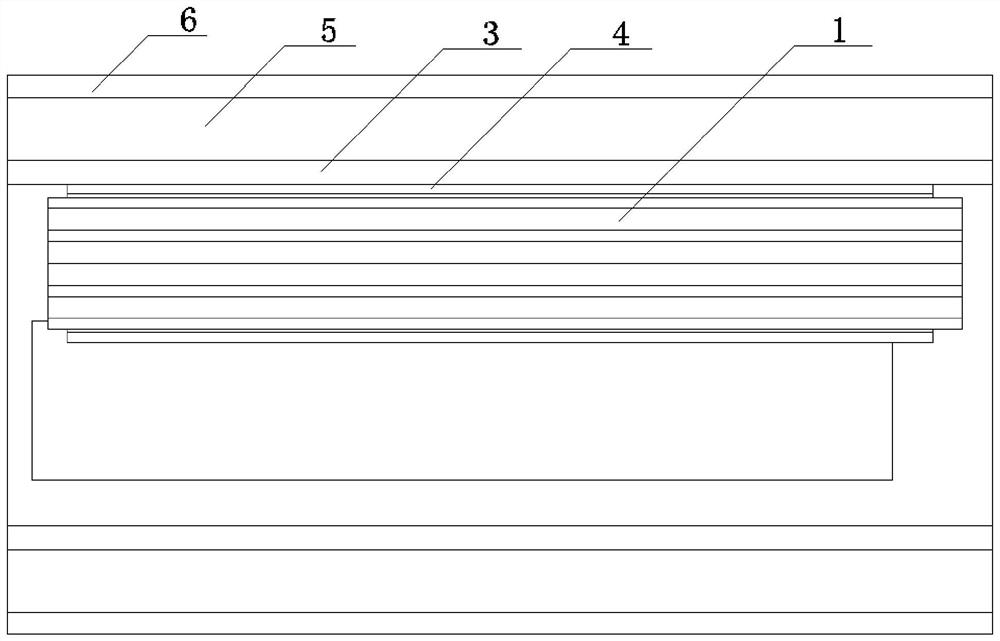

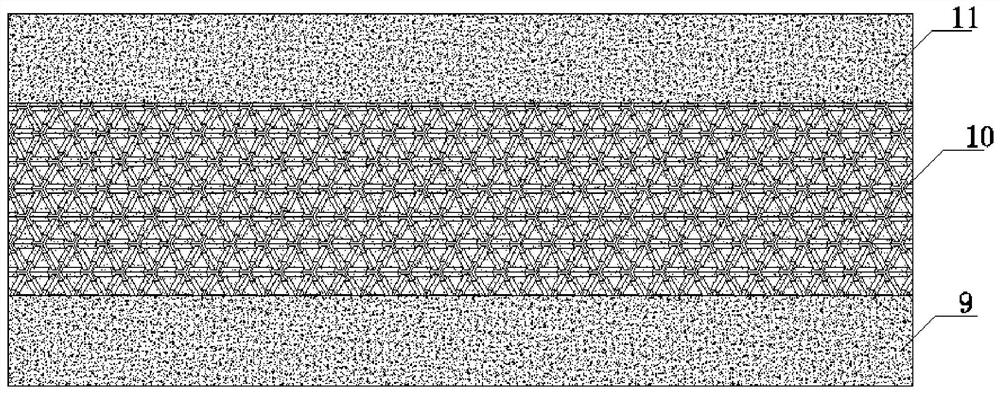

[0036] A high temperature resistant 1000°C electric wire, including multiple sets of conductors 1, and also includes a tape layer 2 and a braided shielding layer 3, the conductor 1 is covered with an insulating layer 4 to form an insulated core, and the three insulated cores are combined and covered with braiding The shielding layer 3 and the braided shielding layer 3 are sequentially covered with an elastic heat insulation layer 5 and a loose tube 6 from the inside to the outside to form the main core, and a reinforcing core 7 is arranged between the multiple main cores, and the multiple main cores are all arranged in the wrapping In the tape layer 2, the tape layer 2 is covered with a braided heat-resistant layer 8, an inner sheath 9, a braided armor layer 10 and an outer sheath 11 from the inside to the outside, and the tape layer 2 is filled with heat-insulating and flame-retardant particles12.

[0037] Among them, a plurality of sub-wire cores 13 are arranged outside the ...

Embodiment 2

[0045] A method for preparing a high-temperature-resistant 1000°C electric wire, comprising the following specific implementation steps:

[0046] Step 1, twisting a plurality of nickel-plated copper wires to form a conductor 1;

[0047] Step 2, extruding a layer of ceramic silicon rubber on the outer periphery of the conductor 1 to form an insulating layer 4, and the insulating layer 2 and the conductor 1 form an insulating core;

[0048]Step 3: Twisting a plurality of insulated wire cores to form a package body and covering the braided layer of silver-plated copper wire to form a braided shielding layer 3; extruding a halogen-free thermoplastic elastomer outside the braided shielding layer 3 to form an elastic heat insulation layer 5 ; A high-bulk fiberglass tube is placed outside the elastic heat insulation layer 5 and coated with iron oxide red silica gel to form a loose tube 6; core;

[0049] Step 4: Extrude a halogen-free thermoplastic elastomer on the outside of the ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com