High-temperature-resistant instrument communication cable

A technology for communication cables and high temperature resistance, applied in communication cables, insulated cables, cables, etc., to achieve the effects of preventing aging catalysis, improving anti-interference ability, and compact structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

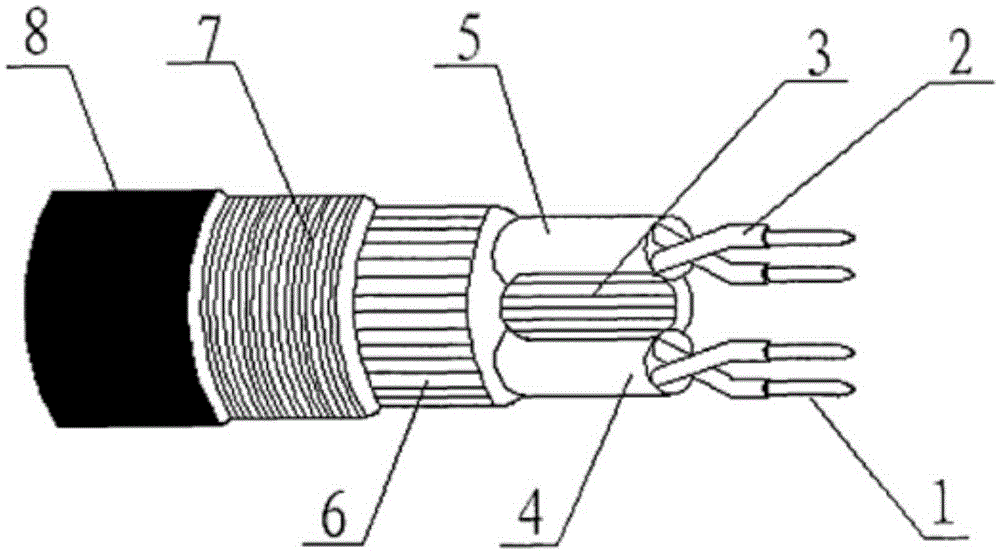

[0009] Such as figure 1 As shown, a high temperature resistant instrument communication cable is composed of a conductor 1, an insulator 2, a filler rope 3, a wrapping layer 4, a wrapping sub-shield 5, a wrapping overall shield 6, a shield body 7 and a sheath 8. The conductor 1 is wrapped with the insulator 2 to form two sets of cable cores, one set of cable cores is wrapped with the wrapping layer 4, and the other set of cable cores is wrapped with the wrapping sub-shield 5 The filling rope 3 is extruded between the two groups of cable cores to form a whole, and the overall wrapping shield 6 is extruded outside, and the shielding body 7 is extruded outside the wrapping overall shield 6, and the shielding The body 7 is extruded with the sheath 8 .

[0010] The present invention is specifically implemented as follows: the insulator 2 is insulated by fluoroplastics, and the insulation thickness on one side is 0.4 mm, and the thinnest point of the insulation is not less than 0.3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com