Method for detecting nonmetallic inclusions in steel

A technology for non-metallic inclusions and detection methods, applied in the field of smelting, can solve problems such as crushing, time-consuming, and complicated extraction process of inclusions, and achieve the effect of avoiding re-precipitation.

- Summary

- Abstract

- Description

- Claims

- Application Information

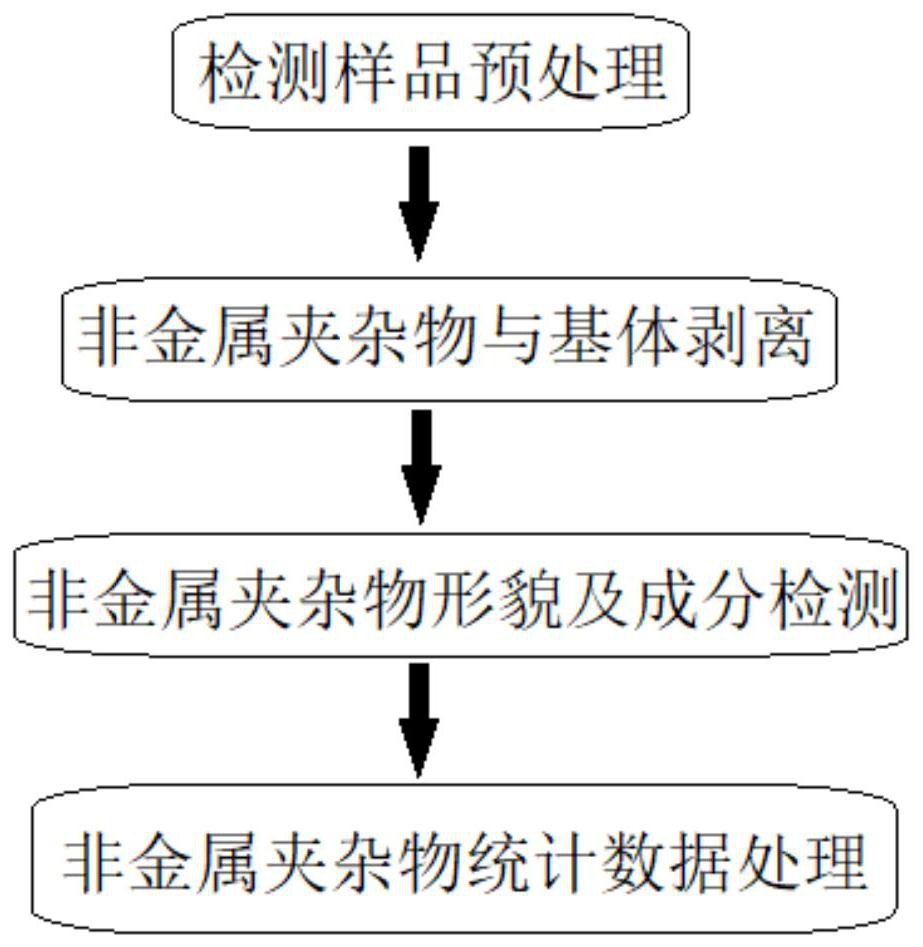

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The steel detected in this embodiment is CLAM steel, and the method for detecting non-metallic inclusions in the steel comprises the following steps:

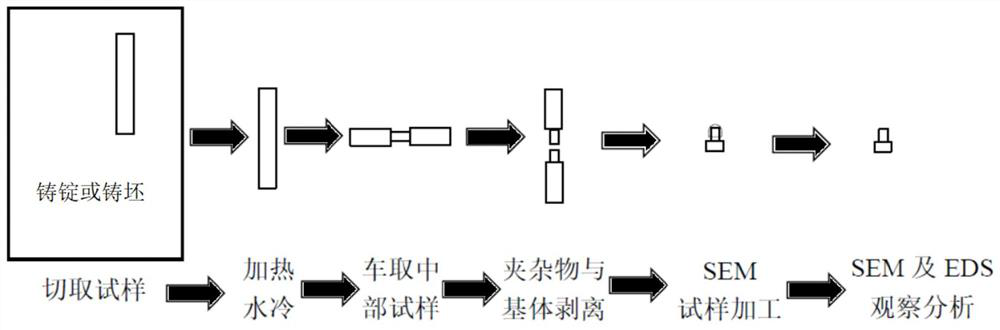

[0041] (1) Test sample pretreatment

[0042] The sample is selected from the ingot of CLAM steel, and the diameter d is cut from the slab by wire cutting 1 = 1cm, length l 1 = 10cm round bar sample; place the round bar sample at 1100°C for 1.5h and then water-cool, and dry the sample as soon as possible after cooling; use a lathe to cut out the diameter d in the middle of the sample after cooling 2 = 5mm long l 2 = 5cm round bar sample, clean the round bar sample for use.

[0043] (2) Non-metallic inclusions are peeled off from the matrix

[0044] The pretreated round bar sample was subjected to tensile failure to peel the inclusions from the matrix and expose the inclusions.

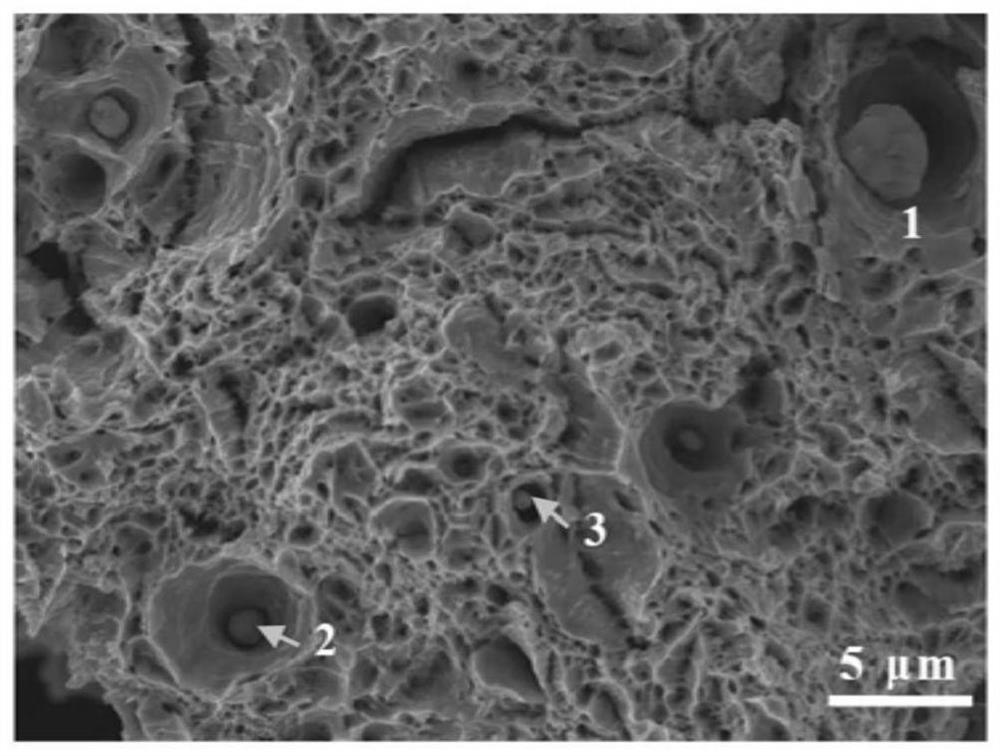

[0045] (3) Morphology and composition detection of non-metallic inclusions

[0046] The sample is processed into a size that can be placed in...

Embodiment 2

[0054] The steel detected in this embodiment is SCRAM, and the method for detecting non-metallic inclusions in the steel comprises the following steps:

[0055] (1) Test sample pretreatment

[0056] The sample is selected from the ingot of SCRAM steel, and the diameter d is cut from the billet by wire cutting 1 =1.5cm, length l 1 = 5cm round bar sample; place the round bar sample at 1200°C for 1.5h and then water-cool, and dry the sample as soon as possible after cooling; use a lathe to cut out the diameter d in the middle of the sample after cooling 2 = 3mm long l 2 = 1 for the round bar sample, clean the round bar sample for use.

[0057] (2) Non-metallic inclusions are peeled off from the matrix

[0058] The pretreated round bar sample was subjected to tensile failure to peel the inclusions from the matrix and expose the inclusions.

[0059] (3) Morphology and composition detection of non-metallic inclusions

[0060] The sample is processed into a size that can be pla...

Embodiment 3

[0068] The steel detected in this embodiment is ARAA steel, and the method for detecting non-metallic inclusions in the steel comprises the following steps:

[0069] (1) Test sample pretreatment

[0070] The sample is selected from the steel ARAA ingot, and the diameter d is cut from the ingot by wire cutting 1 =1.25cm, length l 1 = 7.5cm round bar sample; place the round bar sample at 1150°C for 1.25h and then water-cool, and dry the sample as soon as possible after cooling; use a lathe to cut out the diameter d in the middle of the sample after cooling 2 = 4.5mm long l 2 =1.25 for the round bar sample, clean the round bar sample for use.

[0071] (2) Non-metallic inclusions are peeled off from the matrix

[0072] The pretreated round bar sample was subjected to tensile failure to peel the inclusions from the matrix and expose the inclusions.

[0073] (3) Morphology and composition detection of non-metallic inclusions

[0074] The sample is processed into a size that ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com