Super-weather-resistant metal powder and preparation method thereof

A technology of metal powder and super weather resistance, which is applied in powder coatings, metal-free paints, coatings, etc., and can solve the problems of product aesthetics, low hardness, and service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

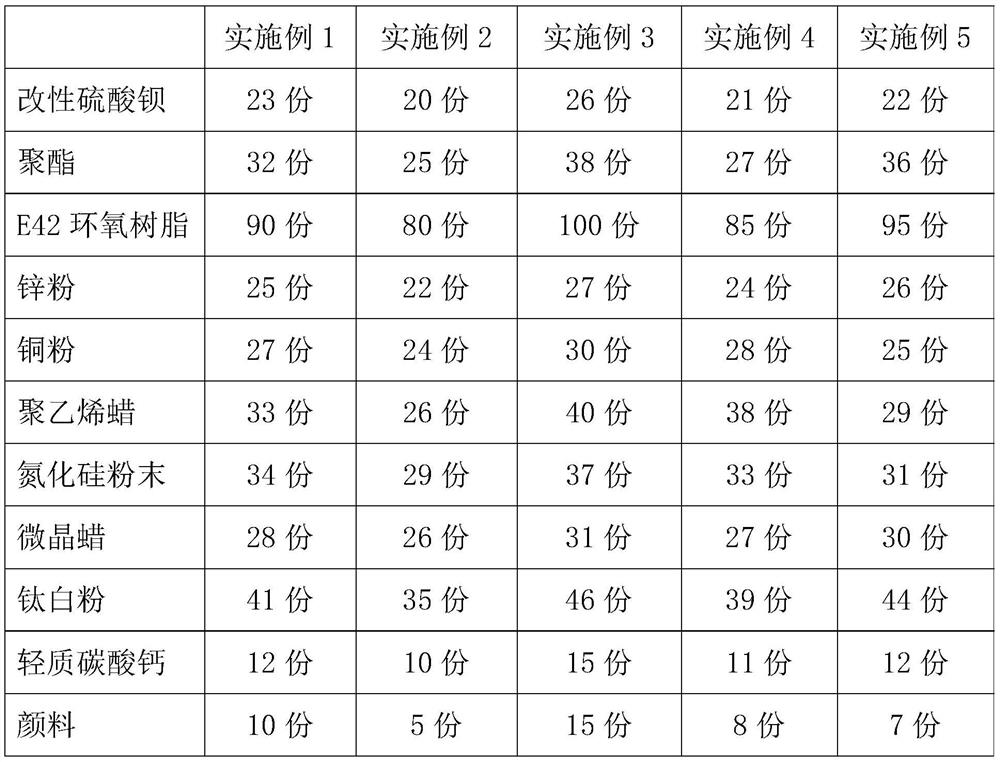

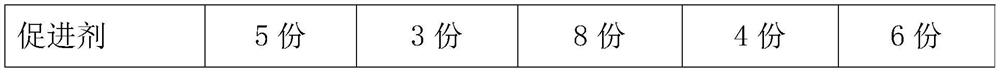

Embodiment 1

[0025] A super-weather-resistant metal powder, the super-weather-resistant metal powder includes: 23 parts of modified barium sulfate, 32 parts of polyester, 90 parts of E42 epoxy resin, 25 parts of zinc powder, 27 parts of copper powder, polyethylene 33 parts of wax, 34 parts of silicon nitride powder, 28 parts of microcrystalline wax, 41 parts of titanium dioxide, 12 parts of light calcium carbonate, 10 parts of pigment, and 5 parts of accelerator.

[0026] Wherein, the pigment is one or a mixture of cinnabar and red clay.

[0027] Wherein, the accelerator is specifically set to be alumina C.

[0028] Among them, polyester is a general term for polymers obtained by polycondensation of polyols and polybasic acids. It mainly refers to polyethylene terephthalate (PET), and customarily also includes linear thermoplastic resins such as polybutylene terephthalate (PBT) and polyarylate. It is a kind of engineering plastic with excellent performance and wide application. It can a...

Embodiment 2

[0042] Different from Example 1, the super-weather-resistant metal powder includes in parts by mass: 20 parts of modified barium sulfate, 25 parts of polyester, 80 parts of E42 epoxy resin, 22 parts of zinc powder, 24 parts of copper powder, 26 parts of polyethylene wax, 29 parts of silicon nitride powder, 26 parts of microcrystalline wax, 35 parts of titanium dioxide, 10 parts of light calcium carbonate, 5 parts of pigment, and 3 parts of accelerator.

Embodiment 3

[0044]Different from Example 1, the super-weather-resistant metal powder includes in parts by mass: 26 parts of modified barium sulfate, 38 parts of polyester, 100 parts of E42 epoxy resin, 27 parts of zinc powder, 30 parts of copper powder, 40 parts of polyethylene wax, 37 parts of silicon nitride powder, 31 parts of microcrystalline wax, 46 parts of titanium dioxide, 15 parts of light calcium carbonate, 15 parts of pigment, and 8 parts of accelerator.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com