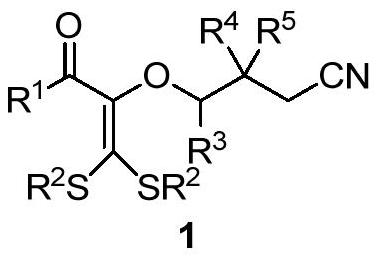

Cyanoalkoxy substituted tetra-substituted olefin derivatives and synthesis thereof

A cyanoalkoxy, tetra-substituted technology, applied in the field of chemical organic synthesis, to achieve the effects of mild conditions, wide applicability and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033]

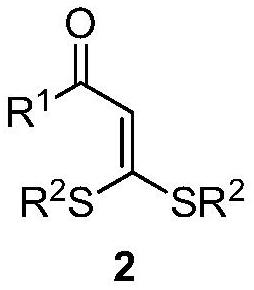

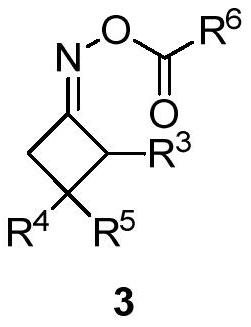

[0034] In a 25mL schlenk tube, add 3,3-dialkylthio-2-propene-1-one compound 2a (0.3mmol), cyclobutanone oxime ester 3a (0.6mmol), copper chloride (10mol%) under oxygen. ) And 3.0 mL trifluorotoluene, stirring at 100°C for 5 hours. After cooling to room temperature, the volatile components were removed under reduced pressure, and then separated by silica gel column chromatography (eluent: petroleum ether (60-90°C) / ethyl acetate, v / v=50:1) to obtain the target product 1a (46.5mg, yield 50%). The target product was confirmed by nuclear magnetic resonance spectroscopy and high-resolution mass spectrometry. In this reaction, oxygen was used as both the reaction gas and the oxidant.

[0035] Compound characterization data

[0036] Cyanoalkoxy substituted tetra-substituted olefin derivative (1a), yellow liquid. 1 H NMR(400MHz, CDCl 3 )δ7.91(m,2H,aromatic CH),7.59(t,J=7.4Hz,1H,aromatic CH),7.49(t,J=7.6Hz,2H,aromatic CH),3.89(t,J=5.6 Hz, 2H, OCH 2 ), 2.57(t,J=7.2Hz,2H,CH 2 CN), ...

Embodiment 2

[0038]

[0039] In a 25mL schlenk tube, add 3,3-dialkylthio-2-propene-1-one compound 2a (0.3mmol), cyclobutanone oxime ester 3a (0.6mmol), copper chloride (10mol%) under nitrogen. ), hydrogen peroxide (0.6mmol) and 3.0mL trifluorotoluene, stirring at 100°C for 5 hours. After cooling to room temperature, the volatile components were removed under reduced pressure, and then separated by silica gel column chromatography (eluent: petroleum ether (60-90°C) / ethyl acetate, v / v=50:1) to obtain the target product 1a (37.0mg, yield 40%). The target product was confirmed by nuclear magnetic resonance spectroscopy and high-resolution mass spectrometry. The characterization data of compound 1a is shown in Example 1.

Embodiment 3

[0041]

[0042] In a 25mL schlenk tube, add 3,3-dialkylthio-2-propene-1-one compound 2b (0.3mmol), cyclobutanone oxime ester 3a (0.6mmol), copper chloride (10mol%) under oxygen. ) And 3.0 mL trifluorotoluene, stirring at 100°C for 5 hours. After cooling to room temperature, the volatile components were removed under reduced pressure, and then separated by silica gel column chromatography (eluent was petroleum ether (60-90°C) / ethyl acetate, v / v=50:1) to obtain the target product 1b (44mg, yield 43%). The target product was confirmed by nuclear magnetic resonance spectroscopy and high-resolution mass spectrometry.

[0043] Compound characterization data

[0044] Cyanoalkoxy substituted tetra-substituted olefin derivative (1b), yellow liquid. 1 H NMR(400MHz, CDCl 3 )δ7.92(m,2H,aromatic CH), 7.59(t,J=7.4Hz,1H,aromatic CH), 7.48(t,J=7.6Hz,2H,aromatic CH), 3.87(t,J=5.6 Hz, 2H, OCH 2 ), 2.88(q,J=7.3Hz,2H,SCH 2 ),2.58(m,4H,SCH 2 and CH 2 CN),1.95(m,2H,OCH 2 CH 2 ),1.31(t,J=7.3Hz,3H,CH 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com