Method for preparing iron ore concentrate and aluminum ore concentrate through suspension co-roasting of red mud and coal gangue

A technology of suspension roasting and coal gangue, applied in chemical instruments and methods, solid separation, cyclone devices, etc., can solve the problems of iron and aluminum resource loss, waste, and reduce the consumption of activation aid alkali, etc., to achieve strong adaptability , improve the effect of dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

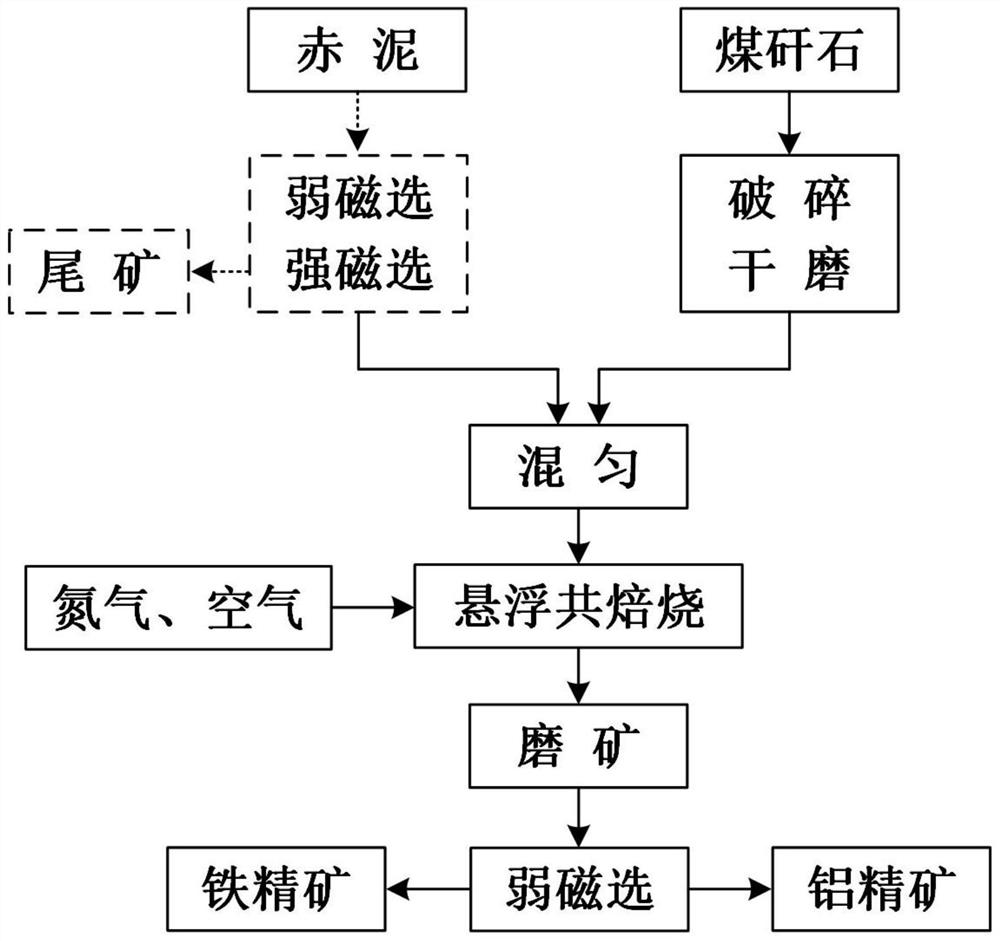

[0043] Process such as figure 1 shown;

[0044] The iron grade of the red mud used is TFe 46.17%, containing Al by mass percentage 2 o 3 12.03%, SiO 2 2.77%, Na 2 O1.9%, of which iron minerals are mainly hematite and goethite;

[0045] The coal gangue used contains Al by mass percentage 2 o 3 27.08%, SiO 2 30.58%, fixed carbon 15.17%, iron grade TFe5.67%, of which aluminum minerals are mainly kaolinite and illite; coal gangue is crushed to a particle size of ≤ 12mm, and then ground to a particle size of -0.038mm to account for the total mass 80%, made into coal gangue powder;

[0046] Mixing the red mud raw material and coal gangue powder to obtain a mixed powder; the mass ratio of the red mud raw material to the coal gangue powder in the mixed powder is 4;

[0047] A suspension high-temperature furnace equipped with a burner at the bottom is adopted. The lower part of the suspension high-temperature furnace is provided with a feed port, and the upper discharge po...

Embodiment 2

[0052] Method is with embodiment 1, and difference is:

[0053] (1) The iron grade TFe of the red mud used is 26.52%, containing Al by mass percentage 2 o 3 17.23%, SiO 2 6.89%, Na 2 O4.3%; the red mud is subjected to weak magnetic separation, the magnetic field strength is 1000Oe, the weak magnetic separation concentrate obtained by weak magnetic separation is subjected to strong magnetic separation, the magnetic field strength of strong magnetic separation is 9000Oe, and the strong magnetic separation concentrate obtained by strong magnetic separation As raw material of red mud, iron grade TFe36.53%, containing Al by mass percentage 2 o 3 13.23%;

[0054] (2) The coal gangue used contains Al by mass percentage 2 o 3 19.08%, SiO 2 32.87%, fixed carbon 10.46%, iron grade TFe 15.67%; crush coal gangue to a particle size ≤ 12mm, and then grind to a particle size of -0.038mm, accounting for 85% of the total mass, and make coal gangue powder;

[0055] (3) The mass rat...

Embodiment 3

[0063] Method is with embodiment 1, and difference is:

[0064] (1) The iron grade TFe of the red mud used is 19.74%, containing Al by mass percentage 2 o 3 20.36%, SiO 2 6.3%, Na 2 O1.7%; the red mud is subjected to weak magnetic separation, the magnetic field strength is 1500Oe, the weak magnetic separation concentrate obtained by weak magnetic separation is subjected to strong magnetic separation, the magnetic field strength of strong magnetic separation is 12000Oe, and the strong magnetic separation concentrate obtained by strong magnetic separation as red mud raw material;

[0065] (2) The coal gangue used contains Al by mass percentage 2 o 3 34.26%, SiO 2 31.59%, fixed carbon 12.16%, iron grade TFe 11.45%; crush the coal gangue to a particle size of ≤12mm, and then grind the part until the particle size is -0.038mm, accounting for 75% of the total mass, and make coal gangue powder;

[0066] (3) The mass ratio of red mud raw material and coal gangue powder in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com