A kind of Gan-based gas sensor and preparation method thereof

A gas sensor and device technology, applied in nanotechnology, instruments, scientific instruments and other directions for sensing, can solve the problems of false signals, poor temperature stability, measurement errors, etc., to eliminate false signals, high integration, improve The effect of temperature stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

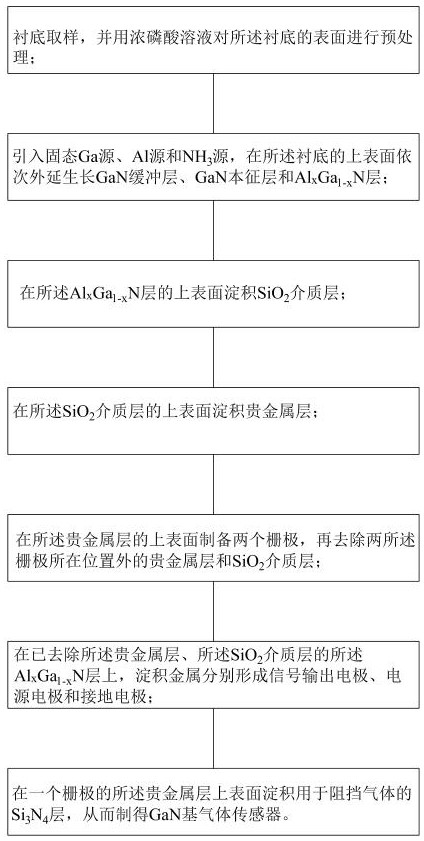

[0031] The invention provides a method for preparing a GaN-based gas sensor, such as figure 1 shown, including the following steps:

[0032] In step S1, the substrate is sampled and the surface of the substrate is pretreated with a concentrated phosphoric acid solution, which can improve the epitaxial growth effect of the GaN buffer layer.

[0033] Step S2, introducing solid Ga source, Al source and NH 3 source, using molecular beam epitaxy technology to sequentially epitaxially grow on the upper surface of the substrate pretreated in step S1: the thickness is 0.1 ~ 1 GaN buffer layer with a thickness of 0.1 ~5 And has a semi-insulating GaN intrinsic layer and Al with a thickness of 10 nm ~ 100 nm x Ga 1-x In the N layer, the Al composition x value ranges from 0.1 to 0.5, and the substrate temperature is 500 o C~800 o C, the growth time is 30min~60min.

[0034] Step S3, using inductively coupled plasma chemical deposition technology in step S2 Al x Ga 1-x SiO w...

Embodiment

[0043] A method for preparing a GaN-based gas sensor, comprising:

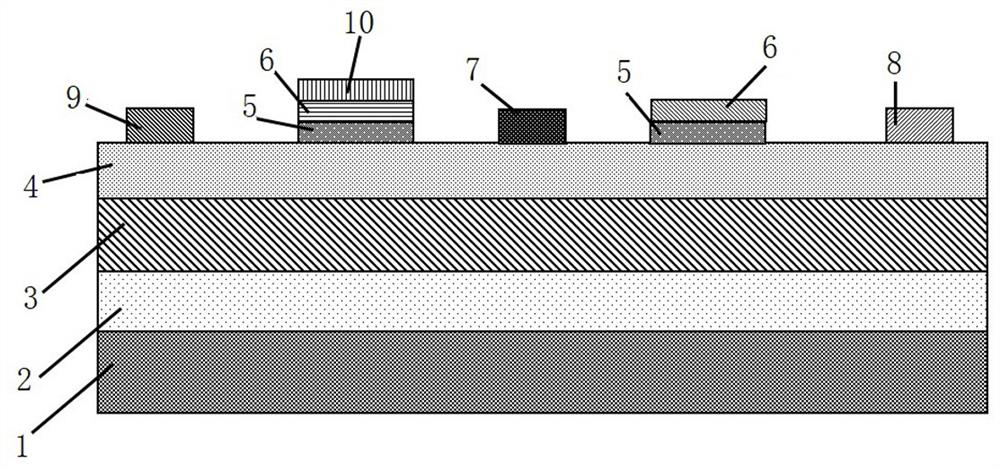

[0044] Step S1, sampling the sapphire substrate 1, and pretreating the surface of the sapphire substrate 1 with a concentrated phosphoric acid solution;

[0045] Step S2, introducing solid Ga source, Al source and NH 3 source, using MBE technology to sequentially epitaxially grow on the upper surface of sapphire substrate 1: 1 Thick GaN buffer layer2,1 Thick GaN intrinsic layer3 and 50 nm thick Al 0.3 Ga 0.7 N layer 4, wherein the temperature of sapphire substrate 1 is 600 o C, the growth time is 40min;

[0046] Step S3, using ICPCVD technology on Al 0.3 Ga 0.7 The upper surface of N layer 4 deposits 50nm thick SiO 2 Medium layer 5;

[0047] Step S4, using sputtering method on SiO 2 A 20nm thick noble metal Pd layer 6 is deposited on the upper surface of the dielectric layer 5;

[0048] Step S5, spin coating 1 on the upper surface of the noble metal Pd layer 6 Thick photoresist, and use ultravio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com