Energy-saving dyeing and finishing method for thin cotton spandex knitted fabric

A technology for knitted fabrics and knitted fabrics, which is applied in the fields of dyeing, fiber types, textiles and papermaking, etc., which can solve the problems of large energy consumption, pollutant discharge, inconformity with energy saving and environmental protection, and complicated mercerizing and singeing processes. Reduce gray cloth strength damage, good dyeing levelness and reproducibility, and avoid local damage to gray cloth strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

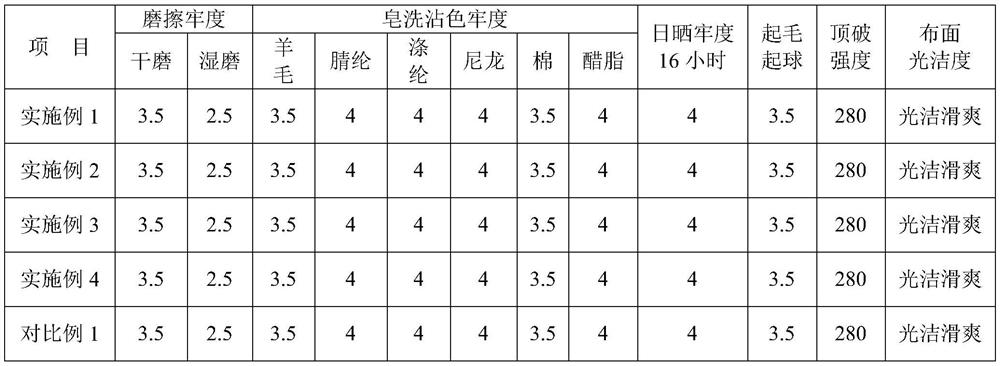

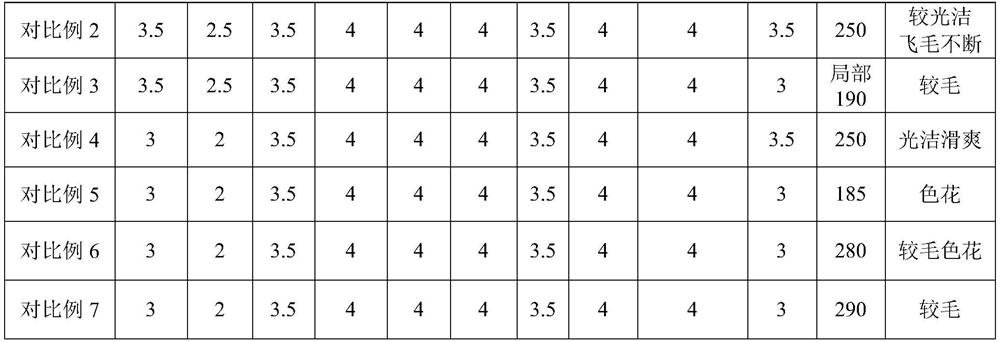

Examples

Embodiment 1

[0040] A method for dyeing and finishing thin cotton spandex knitted fabrics in blue color with energy saving, comprising the following steps:

[0041] (1) Mild mercerizing: add 150g / m 2 The thin all-cotton spandex knitted fabric gray fabric is soaked with liquid alkali in the liquid mandrel using a dipping and rolling process, and then the flat spoke enters the buffer tank for 55 seconds. The liquid alkali used is NaOH solution with a mass concentration of 30%. The amount used is 20% of the total mass of the thin cotton spandex knitted fabric; the process parameters for light mercerization are: rolling pressure 0.4Mpa, rolling rate 85%, and speed of liquid squeezer 19m / min;

[0042] (2) Washing: Put the lightly mercerized gray cloth into a six-tank step-type low-tension open-width washing machine for washing. The temperature of each washing tank is 40°C, and glacial acetic acid is added intermittently in the third tank;

[0043] (3) Pre-setting: the washed gray cloth enters ...

Embodiment 2

[0056] A method for dyeing and finishing thin cotton spandex knitted fabrics in blue color with energy saving, comprising the following steps:

[0057] (1) Mild mercerizing: add 150g / m 2 The thin all-cotton spandex knitted fabric gray fabric is soaked with liquid alkali in the liquid mandrel by one dipping and one rolling process, and then the flat spoke enters the buffer tank for 50 seconds. The liquid alkali used is NaOH solution with a mass concentration of 35%. The amount used is 25% of the total mass of the thin cotton spandex knitted fabric; the process parameters for light mercerization are: rolling rod pressure 0.35Mpa, excess rolling rate 90%, speed of liquid manipulator 18m / min;

[0058] (2) Washing: Put the lightly mercerized gray cloth into a six-tank step-type low-tension open-width washing machine for washing. The temperature of each washing tank is 40°C, and glacial acetic acid is added intermittently in the third tank;

[0059] (3) Pre-setting: the washed gray...

Embodiment 3

[0072] A method for dyeing and finishing thin cotton spandex knitted fabrics in blue color with energy saving, comprising the following steps:

[0073] (1) Mild mercerizing: add 150g / m 2 The thin all-cotton spandex knitted fabric gray cloth is soaked with liquid alkali in the liquid mandrel by one dipping and one rolling process, and then the flat spoke enters the buffer tank for 60 seconds. The liquid alkali used is NaOH solution with a mass concentration of 25%. The amount used is 25% of the total mass of the thin cotton spandex knitted fabric; the process parameters for light mercerization are: rolling rod pressure 0.45Mpa, excess rolling rate 80%, and liquid squeezer speed 20m / min;

[0074] (2) Washing: Put the lightly mercerized gray cloth into a six-tank step-type low-tension open-width washing machine for washing. The temperature of each washing tank is 40°C, and glacial acetic acid is added intermittently in the third tank;

[0075] (3) Pre-setting: the washed gray cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com