Process for preparing poly-p-phenylenebenzobisthiazole (PBO) fiber/benzoxazine composite material

A technology of benzoxazine and composite materials, which is applied in fiber treatment, biochemical fiber treatment, textiles and papermaking, etc., to achieve the effect of low dielectric constant and dielectric loss factor, and high interlayer shear strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

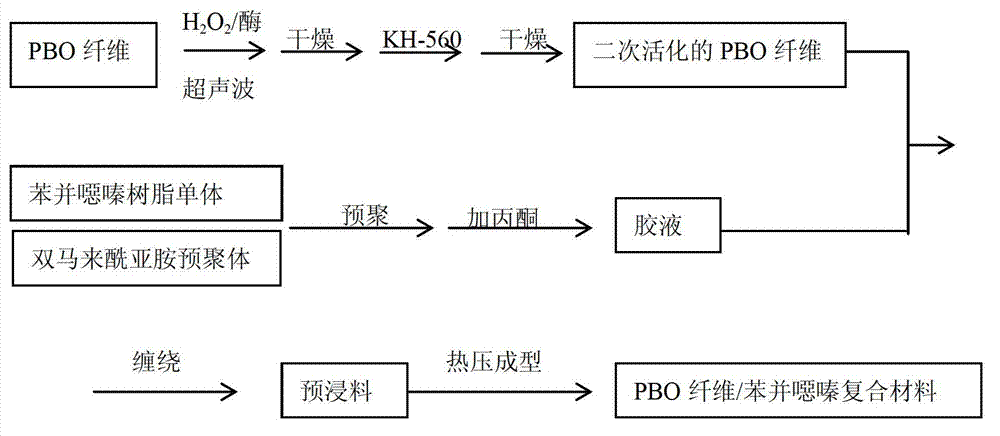

Method used

Image

Examples

Embodiment 1

[0031] The PBO fibers were first immersed in an organic solution containing 0.2% horseradish peroxidase. Under the action of ultrasonic waves of 50-70W, a total of 10 mL of 4wt.% hydrogen peroxide solution was dropped into the system every 5min. After the dropwise addition, the reaction was performed for 0.5-2h. The fibers were taken out, washed with distilled water, and dried. Then, the coupling agent KH-560 was dissolved in acetone, the concentration was controlled at 3.0%, the pH value was adjusted to 3-6, the pretreated PBO fibers were soaked at room temperature for 1-48 hours, washed with distilled water, dried, and used for later use. The bismaleimide prepolymer with a mass fraction of 10% is mixed with the benzoxazine resin monomer, prepolymerized for 1 hour at 120-160 ° C, and then added with a volume fraction of 1 to 5 times. Acetone solution, mixed evenly to make a glue solution for later use. The treated PBO fibers are dipped, wound, and air-dried. The dipping temp...

Embodiment 2

[0033] First, the PBO fibers were immersed in an organic solution containing 0.2% horseradish peroxidase. Under the action of ultrasonic waves of 50-70W, a total of 15mL of 4wt.% hydrogen peroxide solution was dropped into the system every 5min. After the dropwise addition, the reaction was carried out for 0.5-2h, and the fibers were taken out, washed with distilled water, and dried. Then, the coupling agent KH-560 was dissolved in acetone, the concentration was controlled at 3.0%, the pH value was adjusted to 3-6, the pretreated PBO fibers were soaked at room temperature for 24 hours, washed with distilled water, dried, and used for later use. The bismaleimide prepolymer with a mass fraction of 20% is mixed with the benzoxazine resin monomer, prepolymerized at 120-160 ° C for 3 hours, and then added with a volume fraction of 1 to 5 times. Acetone solution, mixed evenly to make a glue solution for later use. The rest of the implementation steps are the same as in Example 1. ...

Embodiment 3

[0035]First, the PBO fibers were immersed in an organic solution containing 0.3% horseradish peroxidase. Under the action of ultrasonic waves of 50-70W, add 20mL of 4wt.% hydrogen peroxide aqueous solution into the system every 5min. After the addition is complete, react for 0.5-2h, take out the fiber, wash it with distilled water, and dry it. Then, dissolve the coupling agent KH-560 in acetone, control the concentration at 3.0%, adjust the pH value to 3-6, soak the pretreated PBO fiber at room temperature for 24 hours, wash with distilled water, dry, and set aside. Mix the bismaleimide prepolymer with a mass fraction of 15% and the benzoxazine resin monomer, prepolymerize at 120-160°C for 2 hours, and then add 1 to 5 times the volume fraction of Acetone solution, mixed evenly to make glue, set aside. The rest of the implementation steps are the same as those in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com