Aramid nanofiber-based layered composite film and preparation method and cyclic utilization method thereof

A technology of nanofibers and composite films, applied in chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve the problem of poor uniformity and compactness, large time consumption, difficulty in large-scale production and practical application Requirements and other issues, to achieve the effect of uniform thickness and excellent comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0093] The present invention also provides a method for preparing an aramid nanofiber-based composite film, comprising the following steps:

[0094] 1) After stirring and stripping the aramid fiber raw material, potassium-containing alkali, proton donor and solvent, an aramid nanofiber dispersion is obtained;

[0095] 2) After shearing and mixing the aramid nanofiber dispersion obtained in the above steps and the assembly element, a composite slurry is obtained;

[0096] 3) Spraying the composite slurry obtained in the above steps on the substrate to form a single-layer two-phase gel layer, and then spraying multiple times to obtain a composite gel;

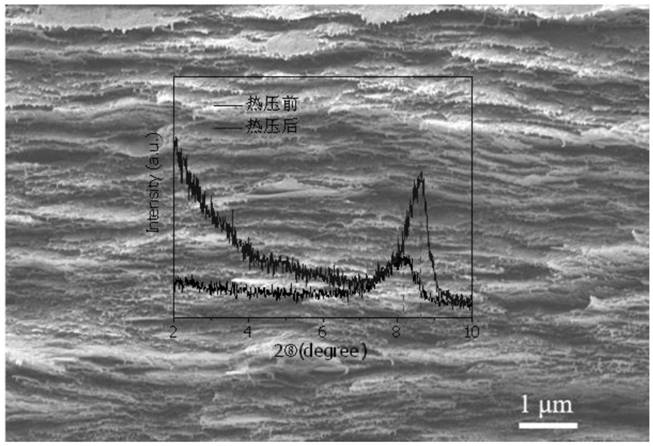

[0097] 4) The composite gel obtained in the above steps is immersed in water for the first replacement, then dried to form a film, immersed in water again for the second replacement, then dried, and then subjected to hot pressing to obtain an aramid nanofiber-based composite film.

[0098] In the present invention, the structure...

Embodiment 1

[0158] Preparation of aramid nanofiber-natural mica nanosheet layered composite film material:

[0159] a. Preparation of aramid nanofiber dispersion: Weigh 20g of commercial aramid fiber, add it to a mixture of 2L dimethyl sulfoxide, 20g potassium hydroxide and 40mL water, and stir it mechanically for 48 hours to form a uniform aramid nanofiber. Fiber dispersion.

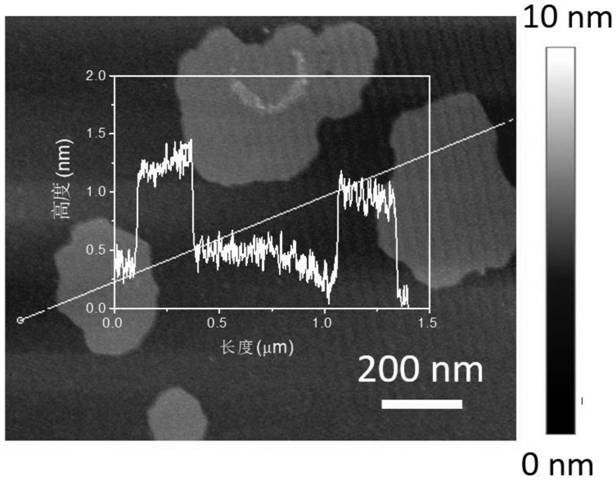

[0160] The aramid nanofiber dispersion prepared in Example 1 of the present invention was characterized.

[0161] see figure 2 , figure 2 It is a transmission electron microscope image of the aramid nanofiber prepared in Example 1 of the present invention.

[0162] Depend on figure 2 It can be seen that the diameter of the aramid nanofiber is about 11 nm.

[0163] b. Preparation of natural mica nanosheets: 50g of natural mica powder is placed in a heating device and heated to 800°C at a heating rate of 10°C / min for 1 hour; then 30g of calcined mica powder is placed in 500mL6mol / L nitric acid solution at 95°...

Embodiment 2

[0180] Preparation of aramid nanofiber-natural mica microsheet composite film material:

[0181]a. The preparation of aramid nanofiber is the same as in Example 1.

[0182] b. Take 26 mica micron flakes and add them to 40mL dimethyl sulfoxide, shake them sufficiently to disperse them evenly, then add them to 4L of 10mg / mL aramid nanofibers, seal and stir to make them evenly dispersed.

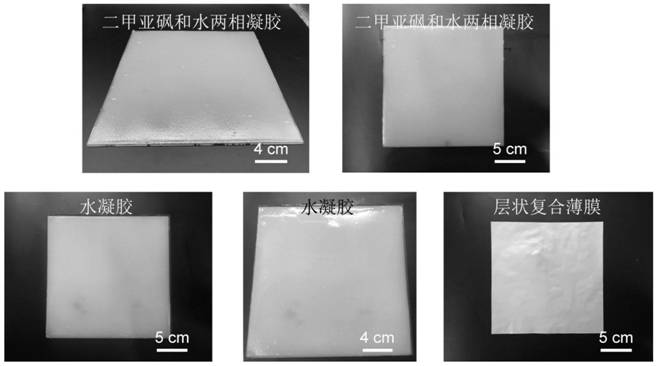

[0183] c. Connect the pipe of the automatic sprayer to the composite slurry, spray through the automatic sprayer, and control the spraying range with the help of the mechanical arm, (device such as Figure 9 shown), within 30 min, 4 L of the slurry was sprayed onto a 40*40 glass substrate to obtain a two-phase hydrogel of dimethyl sulfoxide and water.

[0184] see Figure 9 , Figure 9 It is a schematic diagram of the automatic spraying device adopted in the present invention.

[0185] see Figure 10 , Figure 10 It is an actual photo of the 40wt.% aramid nanofiber-mica layered composite ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com