A kind of geopolymer component and its preparation method

A geopolymer and component technology, applied in the field of building materials, can solve the problems affecting product strength, shorten preparation time, increase economic cost, etc., and achieve the effect of improving mechanical properties such as strength, shortening delivery time, and reducing economic cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

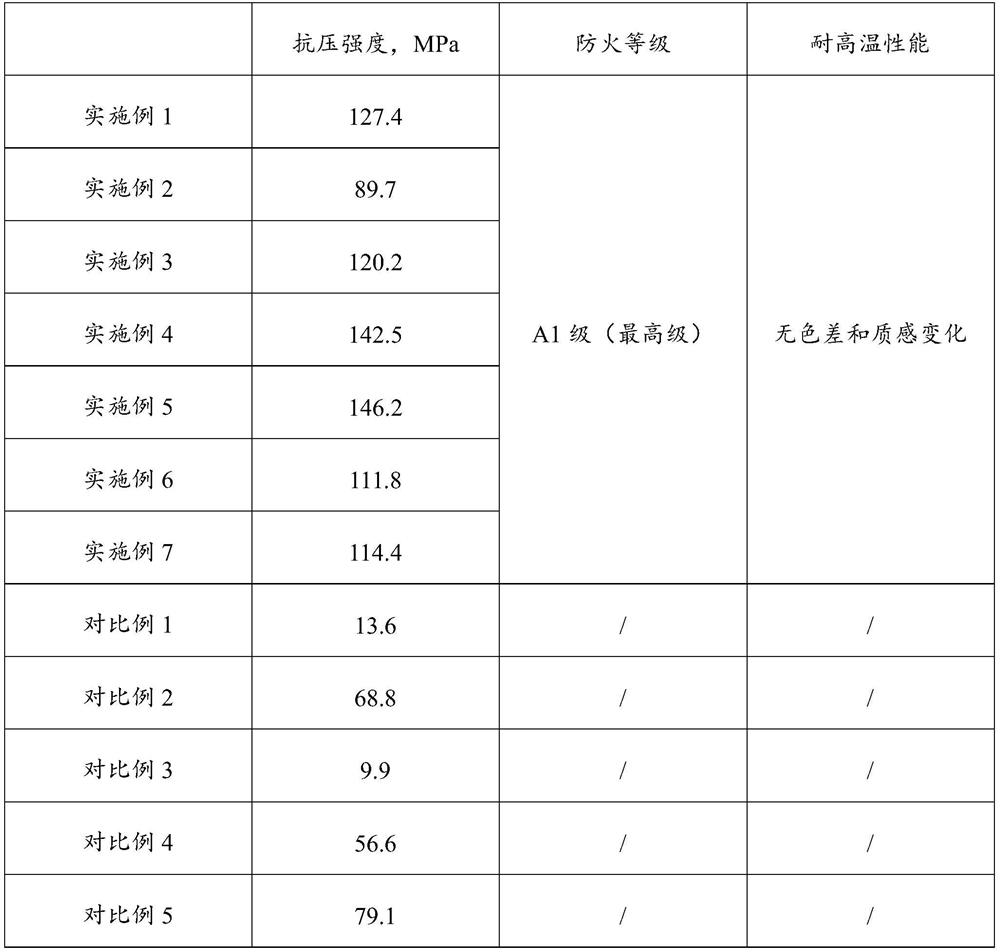

Examples

Embodiment 1

[0054] This embodiment provides a geopolymer component, and the raw materials are weighed in the following parts by weight: metakaolin (silicon-aluminum molar ratio is 1:1, purity is 95%) 58kg, sodium silicate with a modulus of 2.3 4.5kg, hydrogen 1.5kg of sodium oxide, 10kg of water, 3kg of inorganic curing agent (sodium silicate with a modulus of 3.3), and 0.3kg of polycarboxylate water-reducing agent. Then follow these steps to prepare:

[0055] The sodium silicate, sodium hydroxide and water are mixed and stirred evenly by weight, and cooled for 12 hours to obtain a liquid activator;

[0056] Pour the metakaolin, inorganic curing agent and additives into the stirring tank and stir for 5 minutes to mix evenly, then add the activator solution and stir to obtain a semi-dry and wet mixture;

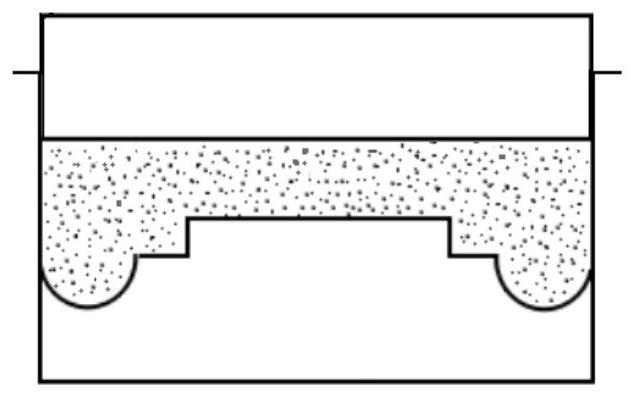

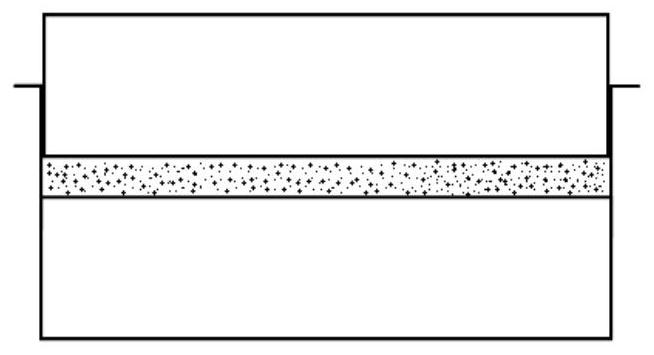

[0057] The semi-dry and wet mixture mixed in the above steps is placed in a steel mold (shaped as figure 2 Fabric treatment is carried out in (shown);

[0058] The materials processed...

Embodiment 2

[0063] This embodiment provides a geopolymer component, and the raw materials are weighed according to the following parts by weight: metakaolin (silicon-aluminum molar ratio is 1:1, purity is 95%) 60kg, sodium silicate 4 with a modulus of 2.3, hydroxide Sodium 2, water 12kg, inorganic curing agent (sodium silicate with a modulus of 3.3) 3kg, polycarboxylate water reducing agent 0.2kg. Then follow these steps to prepare:

[0064] The sodium silicate, sodium hydroxide and water are mixed and stirred evenly by weight, and cooled for 12 hours to obtain a liquid activator;

[0065] Pour the metakaolin, inorganic curing agent and additives into the stirring tank and stir for 5 minutes to mix well, then add the activator solution and stir to obtain a semi-dry and wet mixture;

[0066] The semi-dry and wet mixture mixed in the above steps is placed in a steel mold (shaped as figure 2 Fabric treatment is carried out in (shown);

[0067] The materials processed in the above steps a...

Embodiment 3

[0072] The present embodiment provides a geopolymer component, and the raw materials are weighed in the following parts by weight: metakaolin (silicon-aluminum molar ratio is 1:1, purity is 95%) 68kg, and sodium silicate with a modulus of 2.3 is 4kg. , 4kg of sodium hydroxide, 15kg of water, 5kg of inorganic curing agent (sodium silicate with a modulus of 3.3), and 0.35kg of polycarboxylic acid-based water reducing agent. Then follow these steps to prepare:

[0073] The sodium silicate, sodium hydroxide and water are mixed and stirred evenly by weight, and cooled for 12 hours to obtain a liquid activator;

[0074] Pour the metakaolin, inorganic curing agent and additives into the stirring tank and stir for 5 minutes to mix well, then add the activator solution and stir to obtain a semi-dry and wet mixture;

[0075] The semi-dry and wet mixture mixed in the above steps is placed in a steel mold (shaped as figure 2 Fabric treatment is carried out in (shown);

[0076] The mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com