Low-alkali cement clinker, low-alkali high-strength cement, and preparation method thereof

A low-alkali cement and clinker technology, which is applied in the field of cement manufacturing, can solve problems such as high alkali content, engineering existence, and hidden dangers, and achieve the effects of sufficient reaction, uniform particle size distribution, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

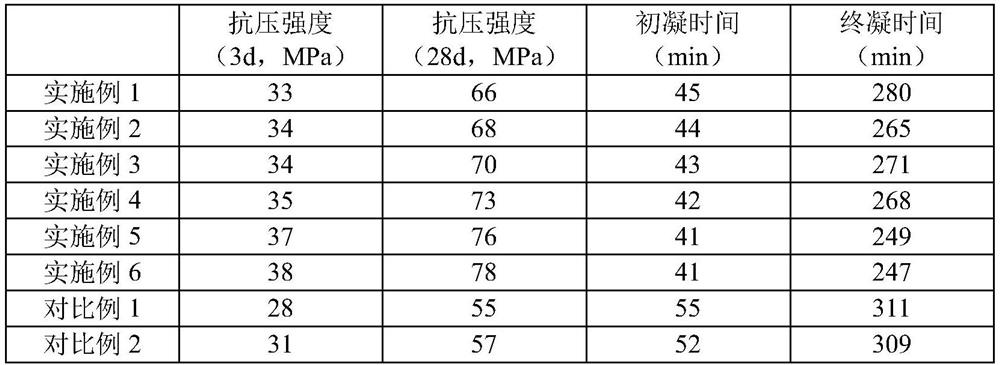

Examples

preparation example Construction

[0051] The preparation method of the low-alkali high-strength cement of the present invention comprises the following steps: 1) uniformly mixing limestone, low-alkali sandstone, sulfuric acid slag, wet fly ash, and fluorine-containing iron ore, and grinding to obtain raw meal; 2) ) Preheating and decomposing the raw meal prepared in step 1), then sintering at 1100-1300°C for 30-40min, cooling to obtain low-alkali cement clinker; 3) making the cement clinker obtained in step 2) Mix it with mixed materials, grind it, and get it.

[0052] The particle size of limestone in step 1) is not greater than 70mm. Step 1) The particle size of the medium-low alkali sandstone is not greater than 80mm. The volume of the 80 μm sieve residue in the raw meal is not more than 10%.

[0053] The temperature of decomposition in step 2) is 890-950°C. The temperature of the cement clinker after cooling in step 2) is not higher than 85°C.

[0054] After preheating and decomposition, the temperatur...

Embodiment 1

[0057] The low-alkali cement clinker of this embodiment is made of the following raw materials in parts by weight: 810 parts of limestone, 50 parts of low-alkali sandstone, 35 parts of sulfuric acid slag, 80 parts of wet fly ash, and 12 parts of fluorine-containing iron ore.

[0058] Limestone is high-quality limestone, the mass fraction of CaO in limestone is 51.3%, the mass fraction of MgO is about 1.6%, R 2 The mass fraction of O is not more than 0.15%. In low alkali sandstone, SiO 2 The mass fraction of R is 86%, R 2 The mass fraction of O is not greater than 0.5%. Fe in sulfuric acid slag 2 o 3 The mass fraction of R is 67%. 2 The mass fraction of O is not greater than 0.5%. Moisture mass fraction in wet fly ash is 12%, Al 2 o 3 The mass fraction is 26%, R 2 The mass fraction of O is not greater than 1.6%. The mass fraction of calcium fluoride in the fluoride-containing iron ore is 14.6%.

[0059] The low-alkali high-strength cement of this embodiment is formed...

Embodiment 2

[0065] The low-alkali cement clinker of this embodiment is made of the following raw materials in parts by weight: 820 parts of limestone, 60 parts of low-alkali sandstone, 30 parts of sulfuric acid slag, 90 parts of wet fly ash, 15 parts of fluorine-containing iron ore, limestone 67 parts of mine waste.

[0066] Limestone is high-quality limestone, the mass fraction of CaO in limestone is 51.3%, the mass fraction of MgO is 1.8%, R 2 The mass fraction of O is not greater than 0.15%. In low alkali sandstone, SiO 2 The mass fraction of R is 86%, R 2 The mass fraction of O is not greater than 0.5%. Fe in sulfuric acid slag 2 o 3 The mass fraction of R is 67%. 2 The mass fraction of O is not greater than 0.5%. Moisture mass fraction in wet fly ash is 12%, Al 2 o 3 The mass fraction is 26%, R 2 The mass fraction of O is not greater than 1.6%. The mass fraction of calcium fluoride in the fluoride-containing iron ore is 14.6%.

[0067] Limestone mine waste is limestone mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com