Heat exchanger applicable to recovery of water heat from ascension tube of coke oven

A waste heat recovery and heat exchanger technology, which is applied in the field of heat exchangers and coke oven riser waste heat recovery heat exchangers, can solve problems affecting heat exchange, deformation of heat exchange tube joints, water leakage, etc., to reduce heat exchange Efficiency, heat transfer efficiency guarantee, effect of guaranteed heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

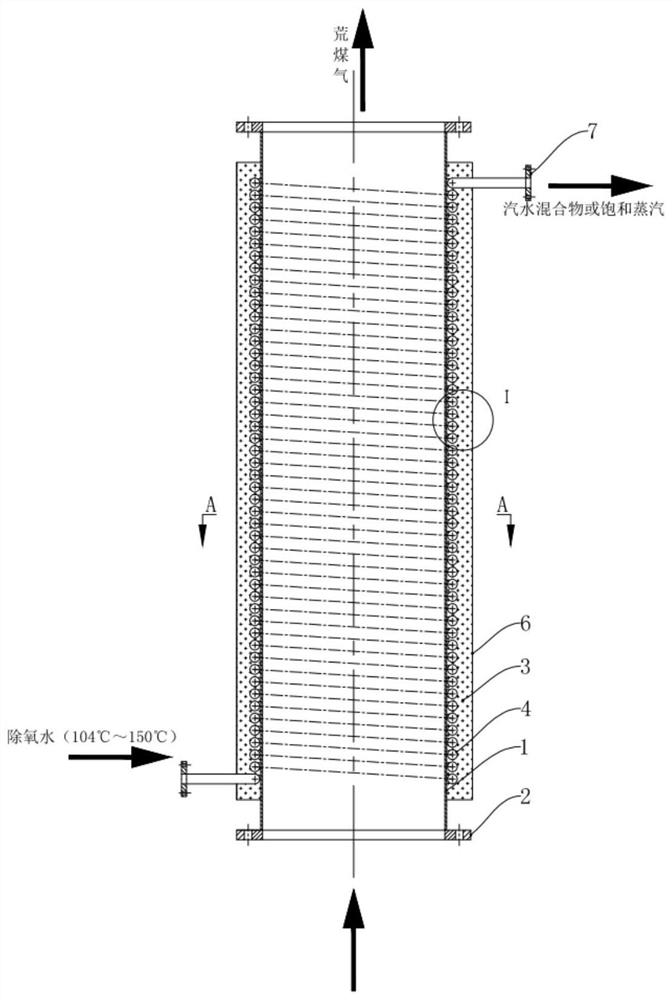

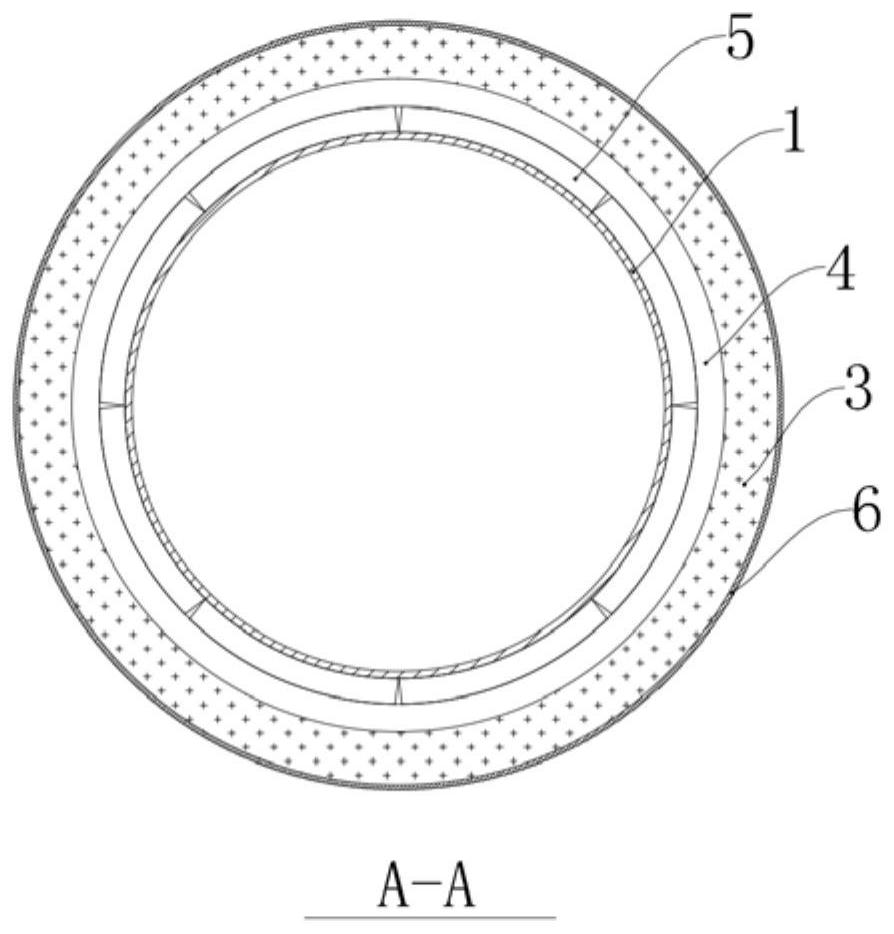

[0036] Such as figure 1Shown: a heat exchanger suitable for waste heat recovery of coke oven riser tube, including: inner tube 1, first flange 2, insulation layer 3, second flange 7, outer tube 6 and heat exchange tube 4, all The inner tube 1 and the outer tube 6 are set concentrically, the heat exchange tube 4 is placed between the inner tube 1 and the outer tube 6; the gap between the inner tube 1, the outer tube 6 and the heat exchange tube 4 is filled and kept warm The material forms the insulation layer 3; the heat exchange tube 4 is circulated with a heat exchange medium, and the heat exchange medium includes deoxygenated water at 104 ° C to 150 ° C; the two ends of the inner tube 1 are respectively connected with the first flange 2 , the inlet end and the outlet end of the heat exchange tube 4 are respectively connected with a second flange 7; the inner tube 1 is arranged vertically, the lower end of the inner tube 1 is the raw gas inlet, and the upper end is the raw ga...

Embodiment 2

[0039] This embodiment is based on embodiment 1, and the difference from embodiment 1 is that the fin 5 is a plate with a non-arc bent cross section.

Embodiment 3

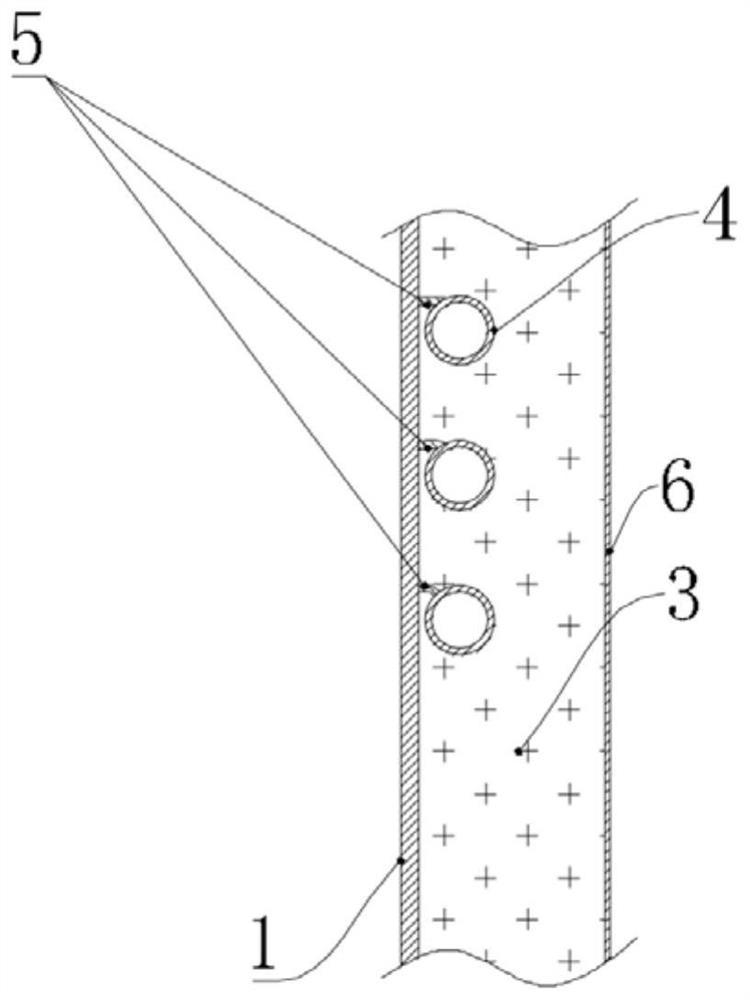

[0041] Such as figure 1 , figure 2 Shown: Based on Embodiment 1 or Embodiment 2, several slits are opened on the fin 5, and the slit connects the outer edge of the fin 5 to the heat exchange tube 4 or the inner edge connected to the inner tube 1 Divide into discrete parts. The heat exchange tubes 4 are helical heat exchange tubes 4 , and the fins 5 are helical fins 5 matching the heat exchange tubes 4 . The slit is helically arranged along the helical direction of the fin 5 , and the slit is a V-shaped slit. Such as image 3 As shown: the number 5 in the figure means that the fins 5 can be in different shapes such as bending and arc.

[0042] The fins 5 are spirally arranged on the outer wall of the inner tube 1, which strengthens the structure of the inner tube 1 to a certain extent, and reduces the influence of the vertical tension in the axial direction brought about by the expansion of the inner tube 1; the thickness of the fins 5 The calculation and selection of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com