Method for preparing nano calcium carbonate by in-situ electrochemical precipitation technology

A nano-calcium carbonate, in-situ electrochemical technology, applied in chemical instruments and methods, calcium carbonate/strontium/barium, inorganic chemistry, etc., to achieve the effect of reducing production costs and efficient comprehensive utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

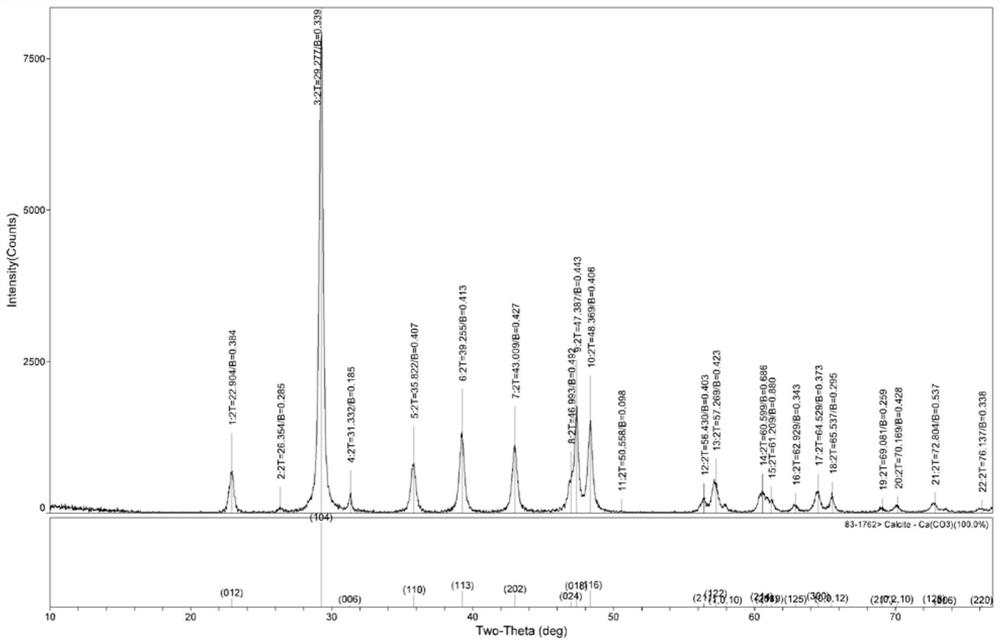

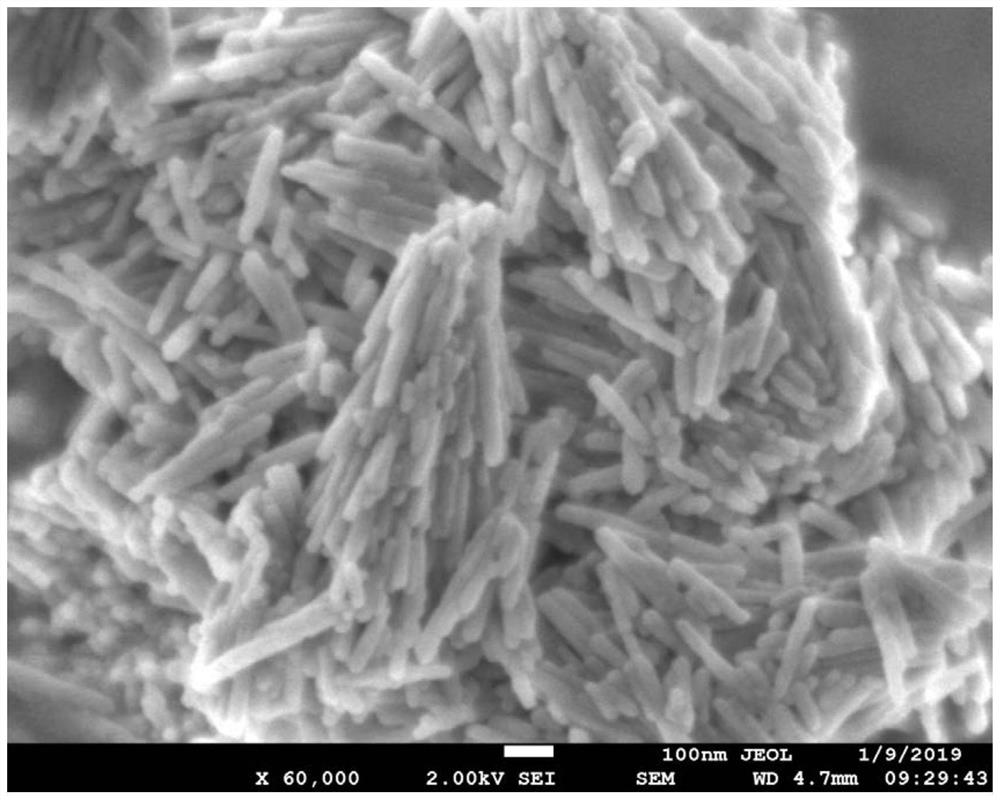

Embodiment 1

[0047] A method for preparing nano-calcium carbonate by in-situ electrochemical precipitation technology, using calcium chloride solution with a concentration of 2.2mol / L as raw material, using a micro-electrolysis system of JM10 cation exchange membrane for electrolysis and calcium ion migration, and controlling the current of the cathode The density is 15A / m 2 Within the range, calcium ions are moved to the cathode chamber, enriched in the form of calcium hydroxide solution, and then citric acid (1% mass concentration percentage) and dispersant ethanol-water solution (ethanol: water=3:1), and with pure CO 2 Carry out the carbonization reaction with the gas, control the reaction temperature at 30°C, carry out the carbonization reaction in a stirred carbonization kettle for 70 minutes, the stirring speed is 700 rpm, and age for 2 hours after the reaction is completed to form nano-calcium carbonate, and the product is obtained by separation and vacuum drying; The CO 2 The gas...

Embodiment 2

[0049] A method for preparing nano-calcium carbonate by in-situ electrochemical precipitation technology, using calcium chloride solution with a concentration of 6mol / L as raw material, using a micro-electrolysis system of JM10 cation exchange membrane for electrolysis and calcium ion migration, and controlling the current density of the cathode 15A / m 2 Within the range, calcium ions are moved to the cathode chamber, enriched in the form of calcium hydroxide solution, and then stearate (0.8% mass concentration percentage) and dispersant propanol-water solution are added to the calcium hydroxide enriched solution in the cathode chamber (propanol: water=2:8), and feed pure CO at a speed of 1000ml / min 2 Carry out the carbonization reaction with the gas, control the reaction temperature at 15°C, carry out the carbonization reaction in a stirred carbonization kettle for 60 minutes, and the stirring speed is 650 rpm, after the reaction is completed, age for 1.5 hours to form nano-ca...

Embodiment 3

[0051] A method for preparing nano-calcium carbonate by in-situ electrochemical precipitation technology, using calcium chloride solution with a concentration of 6mol / L as raw material, using a micro-electrolysis system of JM10 cation exchange membrane for electrolysis and calcium ion migration, and controlling the current density of the cathode 15A / m 2 Within the range, calcium ions are moved to the cathode chamber, enriched in the form of calcium hydroxide solution, and then oleate (0.9% mass concentration percentage) and dispersant tert-butanol-water solution are added to the calcium hydroxide enriched solution in the cathode chamber (tert-butanol: water=4:1), and feed pure CO at a speed of 500ml / min 2 The carbonization reaction is carried out with the gas, the reaction temperature is controlled at 20°C, the carbonization reaction is carried out in a stirred carbonization kettle for 70 minutes, the stirring speed is 660 rpm, after the reaction is completed, it is aged for 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com