Preparation method of slow-release photosynthetic promoting compound fertilizer

A compound fertilizer and slow-release technology, applied in the direction of nitrogen fertilizer, potassium fertilizer, phosphate fertilizer, etc., can solve the problems of high cost and limited use site, and achieve the effect of improving photosynthesis, balanced nutrient components, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

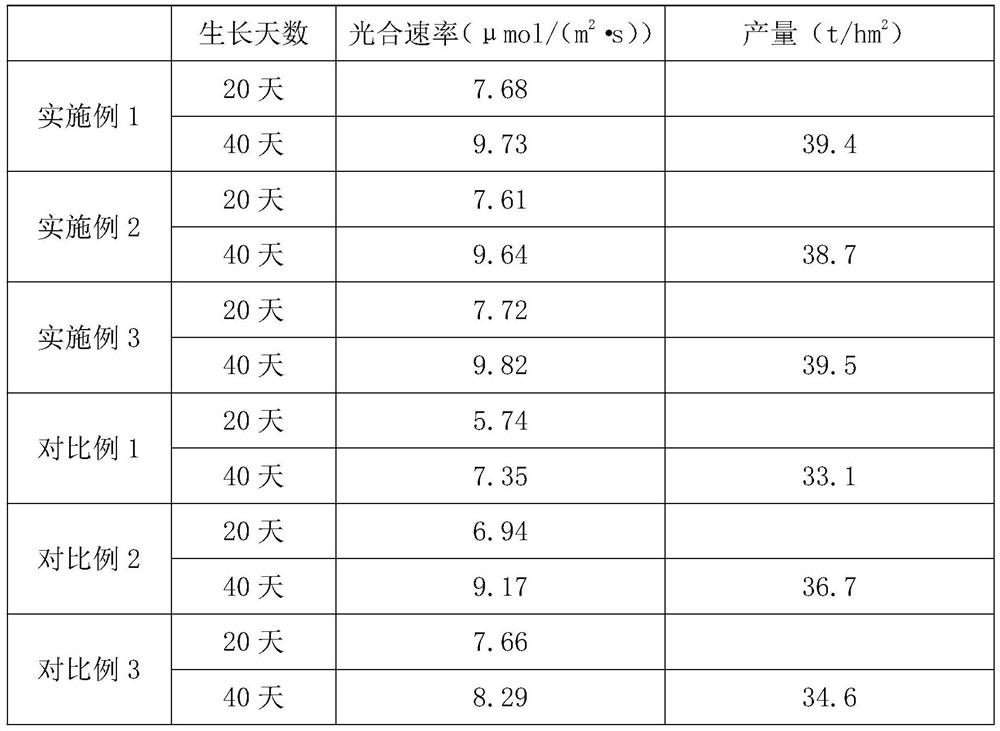

Examples

Embodiment 1

[0027] A preparation method of a slow-release type photosynthesis-promoting compound fertilizer, comprising the following steps:

[0028] (1) Take plant straw, livestock and poultry manure, fulvic acid, and fungus slag, mix them according to the mass ratio of 65:18:7:1, grind them, put them into a fermenter for sealed fermentation, and turn them over every 3 days during fermentation. Turn the bottom fermented material to the top layer one time at a time, control the temperature in the center of the fermented heap to not exceed 70°C during the fermentation period, and continue the fermentation for 20 days to obtain the decomposed fermented material;

[0029] (2) Air-dry the above-mentioned decomposed fermented material and pulverize it through a 40-mesh sieve, then add 3% oxidized glutathione and 10% superphosphate and potassium nitride of the pulverized material to the pulverized material, mix and send Pellet in the granulator, control the particle size between 3-8mm, and re-g...

Embodiment 2

[0033] A preparation method of a slow-release type photosynthesis-promoting compound fertilizer, comprising the following steps:

[0034] (1) Take plant straw, livestock and poultry manure, fulvic acid, and fungus slag, mix them according to the mass ratio of 75:22:9:3, grind them, put them into a fermenter for sealed fermentation, and turn over the pile every 5 days during fermentation. Turn the bottom fermented material to the top layer one time at a time, control the temperature in the center of the fermented heap to not exceed 70°C during the fermentation period, and ferment for 30 days to obtain decomposed fermented material;

[0035] (2) After the above-mentioned decomposed fermented material is air-dried, it is pulverized through a 60-mesh sieve, and then oxidized glutathione and 15% ammonium nitrate and calcium magnesium phosphate fertilizer are added to the pulverized material, and sent into the Granulate in the granulator, control the particle size between 3-8mm, and...

Embodiment 3

[0039] A preparation method of a slow-release type photosynthesis-promoting compound fertilizer, comprising the following steps:

[0040] (1) Take plant straw, livestock and poultry manure, fulvic acid, and fungus slag, mix them according to the mass ratio of 70:20:8:2, crush them, put them into a fermenter for sealed fermentation, and turn over the pile every 4 days during fermentation. Turn the bottom fermented material to the top layer one time at a time, control the temperature in the center of the fermented heap to not exceed 70°C during the fermentation period, and continue the fermentation for 25 days to obtain the decomposed fermented material;

[0041] (2) After air-drying the above-mentioned decomposed fermented material, crush it through a 50-mesh sieve, then add 4% oxidized glutathione and 12% monoammonium phosphate and plant ash to the crushed material, and send it into the mill after mixing. Granulate in the granulator, control the particle size between 3-8mm, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com