Vacuum insulation panel core material, preparation method thereof and vacuum insulation panel

A technology of vacuum insulation panels and core materials, applied in chemical instruments and methods, ceramic products, other household appliances, etc., to achieve the effects of improving stability, slow heat conduction, and good high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

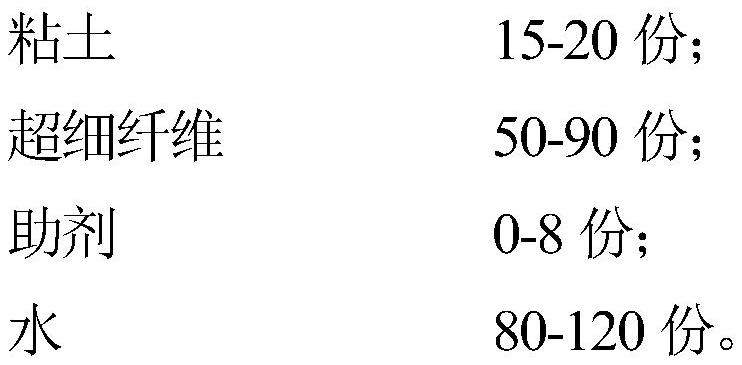

Method used

Image

Examples

Embodiment 1

[0037] The specific process of the preparation process of the core material of the vacuum insulation panel in this embodiment is as follows:

[0038] 1. The raw materials used are composed by parts by weight: 80 parts of superfine carbon fiber; 18 parts of clay, 4.6 parts of polyester fiber, and 150 parts of water.

[0039] The monofilament diameter of the superfine carbon fiber in the raw materials used is about 3 microns, the clay is kaolin or diatomite, and the particle size of the clay is 300-1000 mesh.

[0040] 2. After mixing clay and water in proportion, clay slurry is obtained;

[0041] 3. Add ultra-fine carbon fiber and polyester fiber into the clay slurry, stir evenly to obtain a mixed slurry, and spread the mixed slurry into a rough board after being filtered, and then enter the vacuum equipment to absorb water, and remove the excess clay slurry in the mixed slurry After the material (excess clay slurry accounts for 60-80% of the total weight of the clay slurry) is...

Embodiment 2

[0048] The specific process of the preparation process of the core material of the vacuum insulation panel in this embodiment is as follows:

[0049] 1. The raw materials used consist of 80 parts by weight of superfine glass fiber; 16 parts of clay, 4.6 parts of polyester fiber and 150 parts of water.

[0050] The monofilament diameter of the superfine glass fiber in the raw materials used is about 3 microns, the clay is kaolin or diatomite, and the particle size of the clay is 300-1000 mesh.

[0051] 2. After mixing clay and water in proportion, clay slurry is obtained;

[0052]3. Add ultra-fine glass fiber and polyester fiber into the clay slurry, stir evenly to obtain a mixed slurry, and spread the mixed slurry into a rough board after being filtered, and then enter the vacuum equipment to absorb water, and remove the excess clay in the mixed slurry After the slurry (the excess clay slurry accounts for 60-80% of the total weight of the clay slurry) is sucked out, a blank w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com