Phosphorus-free non-nitrogen scale inhibition dispersant and preparation method thereof

A scale inhibitor and dispersant, maleic acid technology, applied in chemical instruments and methods, scale removal and water softening, water/sludge/sewage treatment, etc. Water environment pollution, complex preparation process and other problems, to achieve the effects of excellent water treatment performance, short polymerization time and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

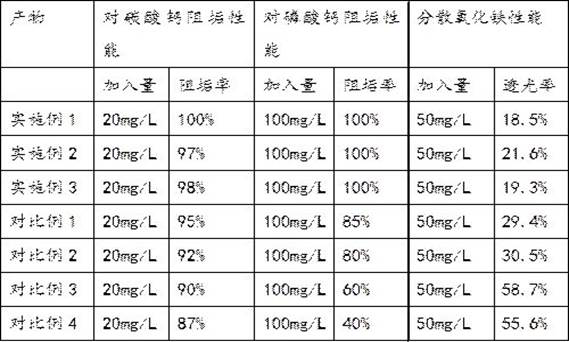

Examples

Embodiment 1

[0023] In the four-necked flask that is furnished with condensing tube, thermometer device, add the itaconic acid IA maleic acid MA that mol ratio is 2:1, add a certain amount of deionized water, the addition of deionized water is itaconic acid and 2 times the total mass of maleic acid, stirred and dissolved. Then add the catalyst ammonium persulfate equivalent to 5% of the total mass fraction of itaconic acid and maleic acid, and the chain transfer agent isopropanol equivalent to 10% of the total mass fraction of IA and MA, heat to 80°C in a water bath, and react for 2 hours. Add sodium methacrylene sulfonate SMAS with the same molar number as maleic acid, and add ammonium persulfate with a mass fraction of 2% sodium methacrylene sulfonate SMAS and deionization equivalent to twice the mass of sodium methacrylene sulfonate SMAS After the water is dissolved, raise the temperature of the water bath to 90°C, continue the reaction for 2 hours, and then cool to room temperature to ...

Embodiment 2

[0025] In a four-neck flask equipped with a condenser tube and a thermometer device, add itaconic acid (IA) maleic acid (MA) with a molar ratio of 2:1, and add a certain amount of deionized water. The amount of deionized water added is Twice the total mass of itaconic acid and maleic acid, stir and dissolve. Then add catalyst ammonium persulfate equivalent to 4% of the total mass fraction of IA and MA and chain transfer agent isopropanol equivalent to 12% of the total mass fraction of IA and MA, heat to 85°C in a water bath, and react for 1.5h. Add sodium methacrylate sulfonate (SMAS) with the same molar number as MA, and add ammonium persulfate with a mass fraction of sodium methacrylate sulfonate of 2.2% and deionized water equivalent to twice the mass of sodium methacrylate sulfonate SMAS , after dissolving, the temperature of the water bath was raised to 90°C, the reaction was continued for 2h, and then cooled to room temperature to obtain a light yellow IA / MA / SMAS polymer...

Embodiment 3

[0027] In a four-neck flask equipped with a condenser tube and a thermometer device, add itaconic acid (IA) maleic acid (MA) with a molar ratio of 2:1, and add a certain amount of deionized water. The amount of deionized water added is Twice the total mass of itaconic acid and maleic acid, stir and dissolve. Then add catalyst ammonium persulfate equivalent to 7% of the total mass fraction of IA and MA and chain transfer agent isopropanol equivalent to 8% of the total mass fraction of IA and MA, heat to 75°C in a water bath, and react for 2h. Add sodium methacrylate sulfonate (SMAS) with the same molar number as MA, and add ammonium persulfate with a mass fraction of sodium methacrylate sulfonate of 1.8% and deionized water equivalent to twice the mass of sodium methacrylate sulfonate SMAS , after dissolving, raise the temperature of the water bath to 90°C, continue the reaction for 1.5h, and then cool down to room temperature to obtain a light yellow IA / MA / SMAS polymer solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com