High-toughness ice-covering-resistant cable

A technology of anti-icing and high toughness, which is applied in the manufacture of power cables, insulated cables, and cables/conductors. It can solve the problems of poor toughness of cable insulation, poor low temperature resistance, and reduced adhesion, and achieve good cold resistance. Excellent water repellency, effect of improving low temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

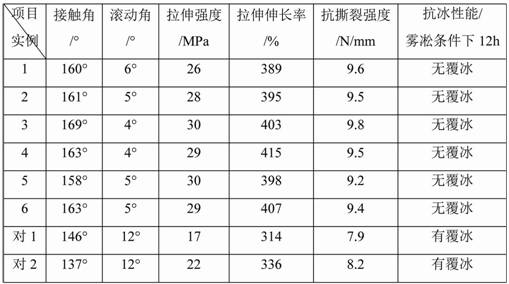

Examples

Embodiment 1

[0022] A high-toughness anti-icing cable, including a core, a shielding layer and an anti-icing layer, the anti-icing layer is made of the following raw materials in parts by weight: 40 parts of fluorosilicone resin, 25 parts of linear low-density polyethylene , 10 parts of maleic anhydride grafted polyethylene, 1 part of stearic acid, 5 parts of magnesium hydroxide, modified Co 3 o 4 3 parts, 10 parts of hydroxyl silicone oil, 1 part of anti-aging agent, 0.5 parts of silane coupling agent and 1 part of accelerator.

[0023] The modified Co 3 o 4 The preparation method comprises the following steps:

[0024] Cobalt subcarbonate 2CoCO 3 3Co(OH) 2 ·H 2 O was calcined in a muffle furnace at 440 °C for 5 h and cooled to room temperature to obtain Co 3 o 4 film, then soaked in 1wt% stearic acid absolute ethanol solution for 1h, removed, and finally dried in an oven at 80°C for 20h to obtain the modified Co 3 o 4 .

[0025] The anti-aging agent is anti-aging agent MB.

...

Embodiment 2

[0034] A high toughness anti-icing cable, including a core, a shielding layer and an anti-icing layer, the anti-icing layer is made of the following raw materials in parts by weight: 43 parts of fluorosilicone resin, 28 parts of linear low-density polyethylene , 12 parts of maleic anhydride grafted polyethylene, 1.5 parts of stearic acid, 6.5 parts of magnesium hydroxide, modified Co 3 o 4 4 parts, 11 parts of hydroxyl silicone oil, 1.2 parts of anti-aging agent, 1 part of silane coupling agent and 1.5 parts of accelerator.

[0035] The modified Co 3 o 4 The preparation method comprises the following steps:

[0036] Cobalt subcarbonate 2CoCO 3 3Co(OH) 2 ·H 2 O was calcined in a muffle furnace at 450 °C for 3 h and cooled to room temperature to obtain Co 3 o 4 film, then soaked in 1.5wt% stearic acid absolute ethanol solution for 2 hours, removed, and finally dried in an oven at 60°C for 24 hours to obtain the modified Co 3 o 4 .

[0037] Described anti-aging agent ...

Embodiment 3

[0044] A high-toughness anti-icing cable, including a core, a shielding layer and an anti-icing layer, the anti-icing layer is made of the following raw materials in parts by weight: 45 parts of fluorosilicone resin, 31 parts of linear low-density polyethylene , 15 parts of maleic anhydride grafted polyethylene, 1.8 parts of stearic acid, 7.5 parts of magnesium hydroxide, modified Co 3 o 4 5 parts, 12.5 parts of hydroxyl silicone oil, 1.5 parts of anti-aging agent, 1.5 parts of silane coupling agent and 2 parts of accelerator.

[0045] The modified Co 3 o 4 The preparation method comprises the following steps:

[0046] Cobalt subcarbonate 2CoCO 3 3Co(OH) 2 ·H 2 O was calcined in a muffle furnace at 450 °C for 4 h and cooled to room temperature to obtain Co 3 o 4 film, then soaked in 1wt% stearic acid absolute ethanol solution for 1h, removed, and finally dried in an oven at 80°C for 24h to obtain the modified Co 3 o 4 .

[0047] The anti-aging agent is anti-aging a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com