Antibacterial anti-penetration fabric

An anti-penetration, fabric technology, used in textiles, textiles and papermaking, dry spinning, etc., can solve the problems of difficult wetting and poor adhesion of the polymer matrix interface, and achieve high density, product controllability, and mild temperature control. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

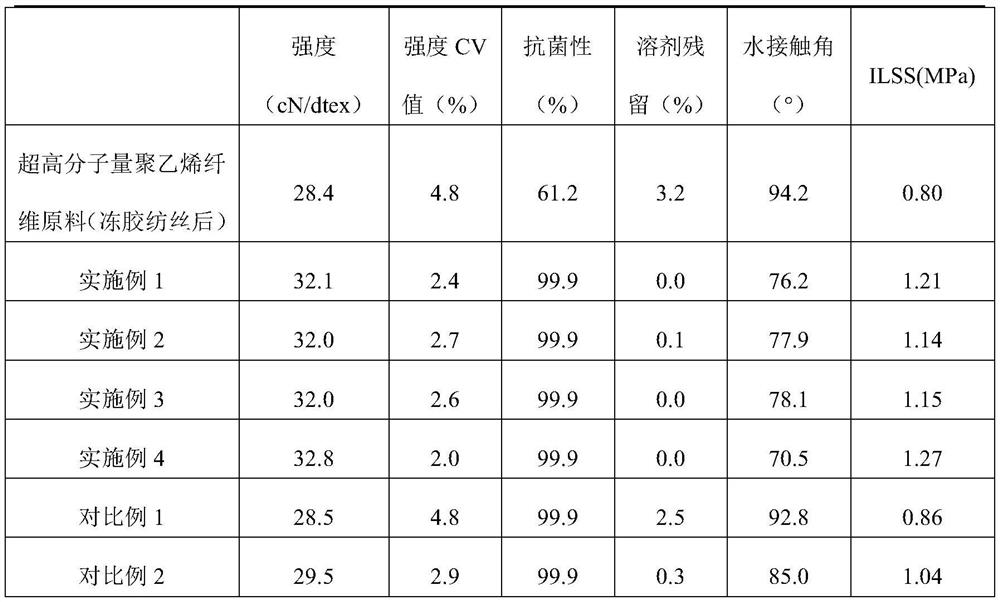

Examples

Embodiment 1

[0023] Embodiment 1: a kind of antibacterial impervious fabric, warp thread and weft all adopt modified ultra-high molecular weight polyethylene fiber, the preparation method of modified ultra-high molecular weight polyethylene fiber comprises the following steps:

[0024] (1) Pre-swelling

[0025] Use ultra-high molecular weight polyethylene fiber (weight average molecular weight 3.5~4.5×10 6 , non-linear rate <5%, the same below) as raw materials, ultra-high molecular weight polyethylene fiber raw materials, n-butanol, dodecyl ethoxy sulfobetaine, nano-silver antibacterial agent and glycerol triacetate by mass Mix at a ratio of 110:6:0.4:0.03:100, place in a swelling reactor and stir, heat up to 90°C and keep it warm for 60 minutes to obtain a pre-swelling liquid;

[0026] (2) Modification solution preparation

[0027] Fumed silica, single-walled carbon nanotubes, microcrystalline cellulose, crospovidone, maleic anhydride, n-butanol, dodecyl ethoxy sulfobetaine, nano-silve...

Embodiment 2

[0030] Embodiment 2: a kind of antibacterial impervious fabric, warp thread and weft all adopt modified ultra-high molecular weight polyethylene fiber, the preparation method of modified ultra-high molecular weight polyethylene fiber comprises the following steps:

[0031] (1) Pre-swelling

[0032] Ultra-high molecular weight polyethylene fiber is selected as raw material, and the raw material of ultra-high molecular weight polyethylene fiber, n-butanol, dodecyl ethoxy sulfobetaine, nano-silver antibacterial agent and glycerol triacetate are mixed in a mass ratio of 107:5 : 0.3:0.02:100 mixed, placed in a swelling reactor and stirred, heated to 88°C and kept warm for 65min to obtain a pre-swelling liquid;

[0033] (2) Modification solution preparation

[0034] Fumed silica, single-walled carbon nanotubes, microcrystalline cellulose, crospovidone, maleic anhydride, n-butanol, dodecyl ethoxy sulfobetaine, nano-silver antibacterial agent and triacetic acid Glycerides are mixed ...

Embodiment 3

[0037] Embodiment 3: a kind of antibacterial impervious fabric, warp thread and weft all adopt modified ultra-high molecular weight polyethylene fiber, the preparation method of modified ultra-high molecular weight polyethylene fiber comprises the following steps:

[0038] (1) Pre-swelling

[0039]Ultra-high molecular weight polyethylene fiber is selected as raw material, and the raw material of ultra-high molecular weight polyethylene fiber, n-butanol, dodecyl ethoxy sulfobetaine, nano-silver antibacterial agent and glycerol triacetate are mixed in a mass ratio of 112:8 : 0.5:0.04:100 mixed, placed in a swelling reactor and stirred, heated to 93°C and kept warm for 55min to obtain a pre-swelling liquid;

[0040] (2) Modification solution preparation

[0041] Fumed silica, single-walled carbon nanotubes, microcrystalline cellulose, crospovidone, maleic anhydride, n-butanol, dodecyl ethoxy sulfobetaine, nano-silver antibacterial agent and triacetic acid Glycerides are mixed a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com