Large-scale 2-series aluminum alloy ingot for civil aircraft and preparation method thereof

An aluminum alloy ingot, large-scale technology, which is applied in the field of 2-series aluminum alloy preparation for civil aircraft, can solve the problem of inability to meet the control requirements of aluminum alloy ingots for civil aircraft, low Fe and Si content ingot cracking, aviation aluminum The problem of high alloy content of alloy materials can solve the problem of composition segregation control, reduce hydrogen content and improve quality indicators.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

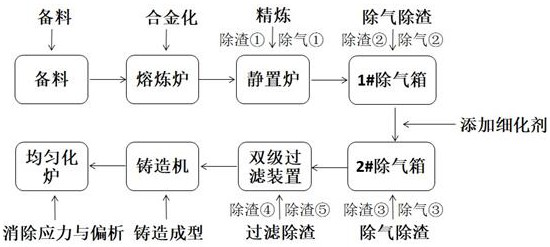

Method used

Image

Examples

Embodiment 1

[0046] Step 1: According to the mass percentage of each substance in the aluminum alloy ingot, and taking into account the burning loss during the alloy smelting process and the alloy composition and content in the scrap, according to the amount of feeding, calculate the aluminum ingot, copper plate, magnesium ingot, and aluminum manganese. Alloy, aluminum-chromium master alloy, aluminum-titanium master alloy, aluminum-zirconium master alloy, and according to the calculation results, weigh various raw materials, including copper plate, magnesium ingot, aluminum-manganese master alloy, aluminum-chromium master alloy, aluminum-titanium master alloy , Aluminum-zirconium master alloy needs to be divided into small pieces in advance and then weighed.

[0047] Step 2: Put the fully dried aluminum ingots into the melting furnace, and control the furnace temperature to 950°C during the melting process; after the aluminum ingots are completely melted, use electromagnetic stirring equipm...

Embodiment 2

[0055] Step 1: According to the mass percentage of each substance in the aluminum alloy ingot, and taking into account the burning loss in the alloy smelting process and the alloy composition and content in the scrap, according to the amount of feeding, calculate the aluminum ingot, copper plate, magnesium ingot, and aluminum manganese. Alloy, aluminum-chromium master alloy, aluminum-titanium master alloy, aluminum-zirconium master alloy, and according to the calculation results, weigh various raw materials, including copper plate, magnesium ingot, aluminum-manganese master alloy, aluminum-chromium master alloy, aluminum-titanium master alloy , Aluminum-zirconium master alloy needs to be divided into small pieces in advance and then weighed.

[0056] Step 2: put the fully dried aluminum ingots into the melting furnace, and control the furnace temperature to 950°C during the melting process; after the aluminum ingots are completely melted, stir for 30 minutes with an electromagn...

Embodiment 3

[0064] Step 1: According to the mass percentage of each substance in the aluminum alloy ingot, and taking into account the burning loss in the alloy smelting process and the alloy composition and content in the scrap, according to the amount of feeding, calculate the aluminum ingot, copper plate, magnesium ingot, and aluminum manganese. Alloy, aluminum-chromium master alloy, aluminum-titanium master alloy, aluminum-zirconium master alloy, and according to the calculated results, weigh various raw materials, including copper plate, magnesium ingot, aluminum-manganese master alloy, aluminum-chromium master alloy, aluminum-titanium master alloy Alloys and aluminum-zirconium master alloys need to be divided into small pieces in advance before weighing;

[0065] Step 2: Put the fully dried aluminum ingots into the melting furnace, and control the furnace temperature to 1000°C during the melting process; after the aluminum ingots are completely melted, stir for 20 minutes with an ele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com