Gamma-ray-resistant anti-aging transparent polypropylene composite material and preparation method thereof

A transparent polypropylene and composite material technology, applied in the field of polypropylene materials, can solve the problems of limiting the application of PP materials, deterioration of physical and mechanical properties, loss of use performance, etc., to achieve weakened post-irradiation effects, excellent transparency, and enhanced dispersion sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

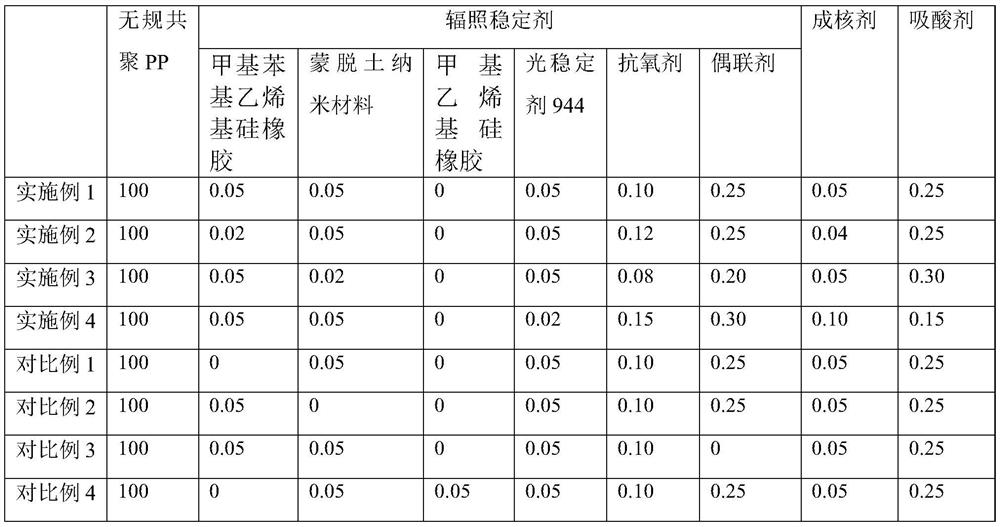

Embodiment 1-4 and comparative example 1-4

[0053] Weigh each raw material component according to the parts by weight shown in Table 1 below, add it to a high-speed mixer and stir for 10 minutes to mix evenly, then add it to a twin-screw extruder for melt extrusion, and the temperature of the extruder is set as: feeding to The temperature of the die section is 120°C-180°C, the temperature of the head and the die is 185-200°C, and the screw speed of the main engine is 300-500r / min. After melt extrusion, the final product polypropylene composite material can be obtained after pelletizing and drying.

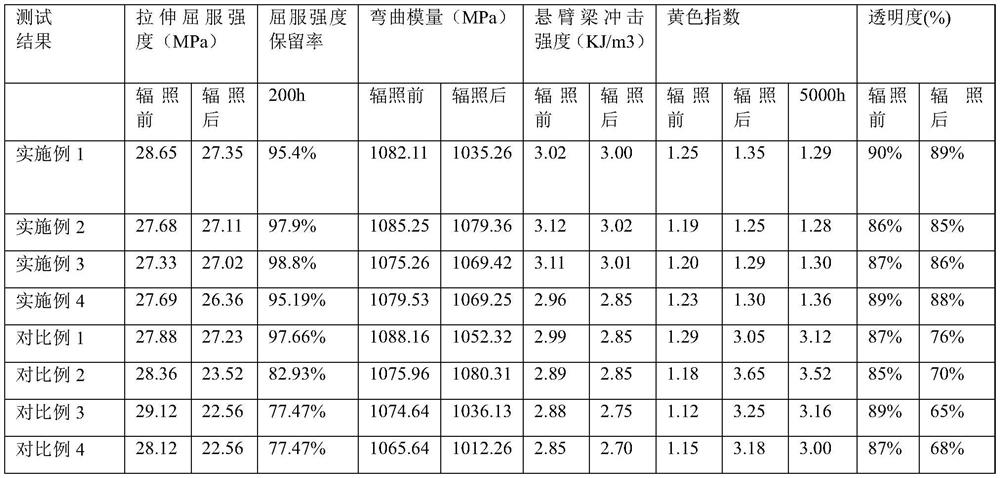

[0054] Samples were prepared for the prepared polypropylene composite material and various properties were tested before and after irradiation (irradiation dose was 50KGy), and the results were recorded in Table 2 below.

[0055] The random copolymerized polypropylene in the examples is the random copolymerized polypropylene PPR7227 produced by Total.

[0056] The acid absorbing agent uses calcium stearate.

[0057] As the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com