A kind of environment-friendly flame-retardant colored cake and preparation method thereof

An environmentally friendly, color cake technology, applied in the field of polymer chemistry, can solve problems such as non-compliance, and achieve the effects of improving uniformity, enhancing dispersion performance, improving stability and dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

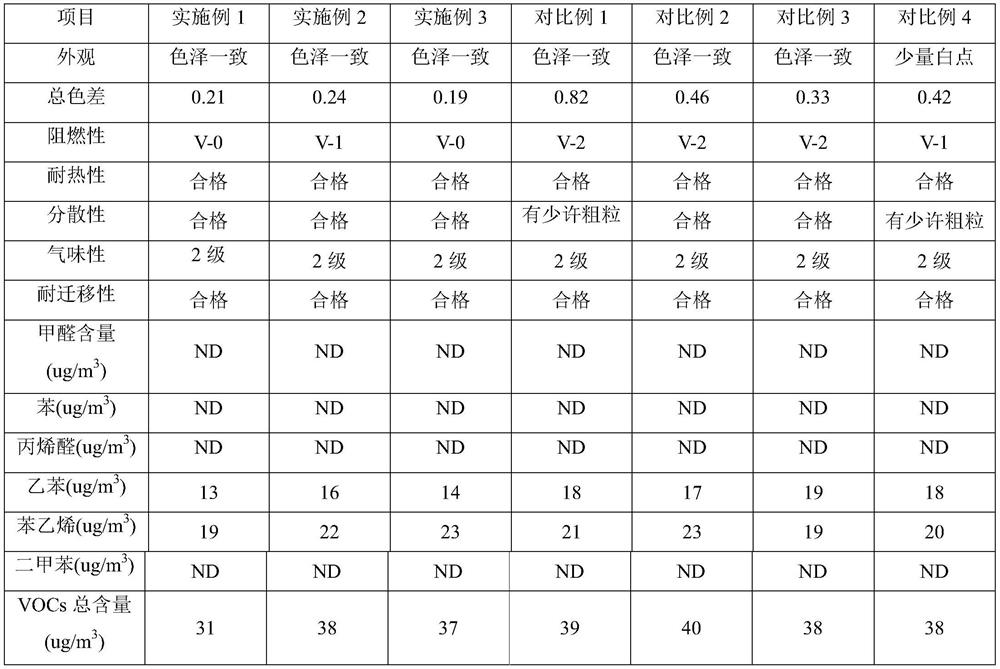

Examples

Embodiment 1

[0058] The preparation method of modified nano calcium carbonate:

[0059] Weigh the nano-calcium carbonate powder, add the weighed nano-calcium carbonate powder into the ethanol solution of γ-aminopropyltriethoxysilane, wherein the content ratio of γ-aminopropyltriethoxysilane to absolute ethanol is 0.1 g: 100mL, keep the temperature at 65°C, and ultrasonically react for 50 minutes; cool down, centrifuge, discard the supernatant, and dry to obtain the modified nano-calcium carbonate dispersant.

[0060] A flame retardant and environmentally friendly color cake formula:

[0061] The flame-retardant and environmentally friendly color cake of Example 1 of the present invention is made of the following components in parts by weight, wherein, polyvinyl chloride: 8 parts, antimony trioxide and magnesium hydroxide combined flame retardant: 65 parts, of which The weight ratio of antimony and magnesium hydroxide is 15:1, the composition of epoxy soybean oil and TOTM: 0.5 part, wherei...

Embodiment 2

[0064] The preparation method of modified nano calcium carbonate:

[0065] Weigh nano-calcium carbonate powder, add the weighed nano-calcium carbonate powder into N-β-aminoethyl-γ-aminopropyltriethoxysilane ethanol solution, wherein N-β-aminoethyl-γ-ammonia The content ratio of propyltriethoxysilane to absolute ethanol is 0.8g:100mL, keep the temperature at 75°C, and ultrasonically react for 30 minutes; cool down, centrifuge, discard the supernatant, and dry to obtain modified nano-calcium carbonate Dispersant.

[0066] A flame retardant and environmentally friendly color cake formula:

[0067] The flame-retardant and environmentally friendly color cake of Example 2 of the present invention is made of the following components in parts by weight, wherein 15 parts of polyethylene, antimony trioxide and aluminum hydroxide combined flame retardant: 85 parts, of which antimony trioxide The weight ratio of epoxy soybean oil and 911P is 15:0.5, the composition of epoxy soybean oil ...

Embodiment 3

[0070] The preparation method of modified nano calcium carbonate:

[0071] Weigh nano calcium carbonate powder, add the weighed nano calcium carbonate powder into N-β-aminoethyl-aminopropylmethyldimethoxysilane ethanol solution, wherein N-β-aminoethyl-aminopropyl The content ratio of methyldimethoxysilane to absolute ethanol is 0.2g:100mL, keep the temperature at 70°C, and ultrasonically react for 35min; cool down, centrifuge, discard the supernatant, and dry to obtain modified nano-calcium carbonate Dispersant.

[0072] A flame retardant and environmentally friendly color cake formula:

[0073] The flame-retardant and environmentally friendly color cake of Example 3 of the present invention is made of the following components in parts by weight, wherein, polyvinyl chloride: 10 parts, antimony trioxide, aluminum hydroxide, magnesium hydroxide combined flame retardant: 80 parts , wherein the weight ratio of antimony trioxide, aluminum hydroxide and magnesium hydroxide is 15:0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com