Aluminum alloy thick plate multi-layer laser-TIG hybrid welding device and method

A hybrid welding and welding method technology, applied in laser welding equipment, welding equipment, welding/welding/cutting items, etc., can solve the problems of low filling and cover welding efficiency, poor laser gap adaptability, and poor welding stability, etc. It is not easy to weld spatter, prolong the solidification time, and stabilize the welding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

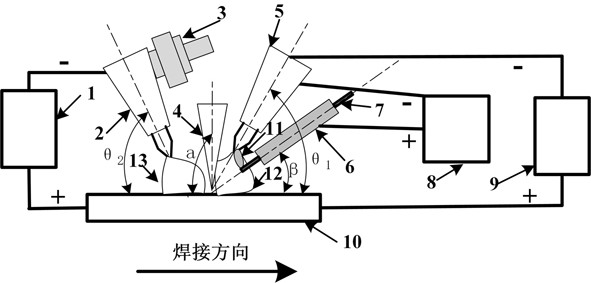

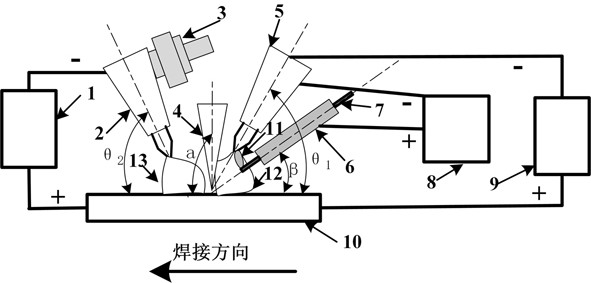

[0031] Such as figure 1 with 2 As shown, a multilayer laser-TIG composite welding device for aluminum alloy thick plates includes a first TIG power supply 9, a second TIG power supply 1 and a hot wire power supply 8, wherein the negative pole and positive pole of the first TIG power supply 9 are respectively connected to the first TIG power supply 9 A TIG torch 5 is connected to the aluminum alloy thick plate 10 to be welded, thereby forming a molten pool arc 12 between the first TIG welding torch 5 and the aluminum alloy thick plate 10 to be welded; A TIG welding torch 5 is connected to the welding wire 7, thereby forming a fuse arc 11 between the first TIG welding torch 5 and the bottom end of the welding wire 7; The welding aluminum alloy thick plate 10 is connected, thereby forms heating arc 13 between the second TIG welding torch 2 and the aluminum alloy thick plate 10 to be welded, and between the first TIG welding torch 5 and the second TIG welding torch 2 there is a d...

Embodiment 2

[0041] This embodiment is an improvement made on the basis of Embodiment 1. Its main structure is the same as that of Embodiment 1. The improvement is that the first TIG welding torch 5 is controlled by an ultrasonic horn 3 during the welding process. , reciprocating vibration along the welding direction.

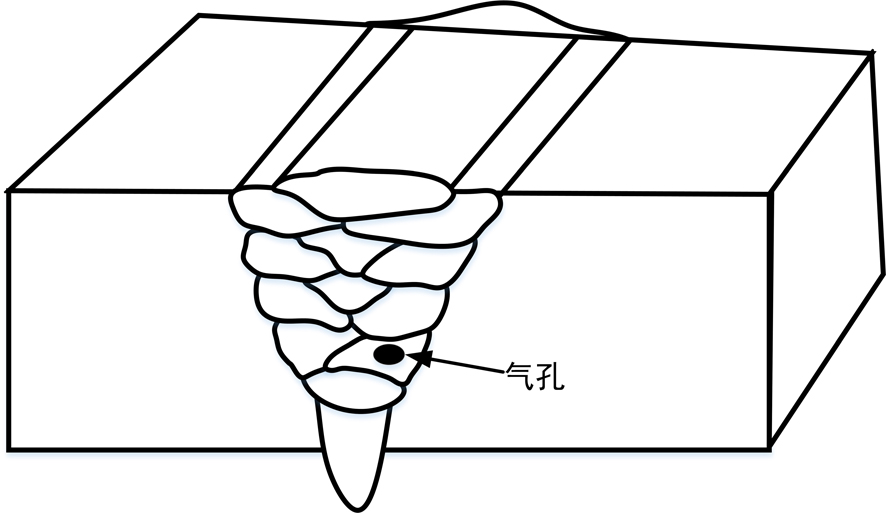

[0042] In this embodiment, by adding the ultrasonic horn 3, the ultrasonic vibration generated can stir the molten pool, and at the same time prolong the solidification time of the molten pool, which is conducive to the escape of welding bubbles from the molten pool and reduces the weld porosity of the backing welding .

[0043] The ultrasonic vibration frequency of the ultrasonic horn 3 is preferably 5-900 kHz, and the vibration amplitude is preferably 1-10 um.

Embodiment 3

[0045] This embodiment is another improvement made on the basis of embodiment 1. Its main structure is the same as that of embodiment 1. The improvement is that before performing the bottom welding, it is necessary to weld the aluminum alloy thick plate 10 Process a Y-shaped or U-shaped groove, and at the same time, carry out surface treatment on the welded workpiece. Surface treatment refers to removing impurities on the surface of the welded workpiece, and then connect the welded workpiece to the groove of the aluminum alloy thick plate 10 to be welded and fix it with a welding fixture .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com