Porous fiber liquid absorption core with carbon nano tubes grown on surface in situ and preparation method

A carbon nanotube and porous fiber technology is applied in the field of porous fiber absorbent core and preparation, which can solve the problems of large backflow resistance and small capillary force, and achieve the effects of preventing local overheating, simple manufacturing process and uniform temperature distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with specific embodiments.

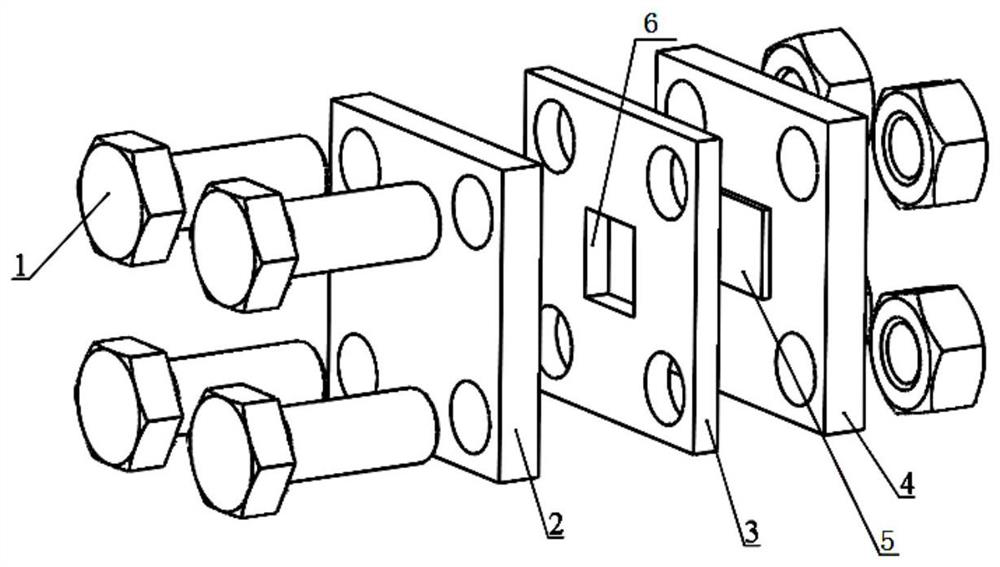

[0025] The preparation process of the porous fiber liquid-absorbent core with in-situ growth of carbon nanotubes on the surface of the present invention is as follows:

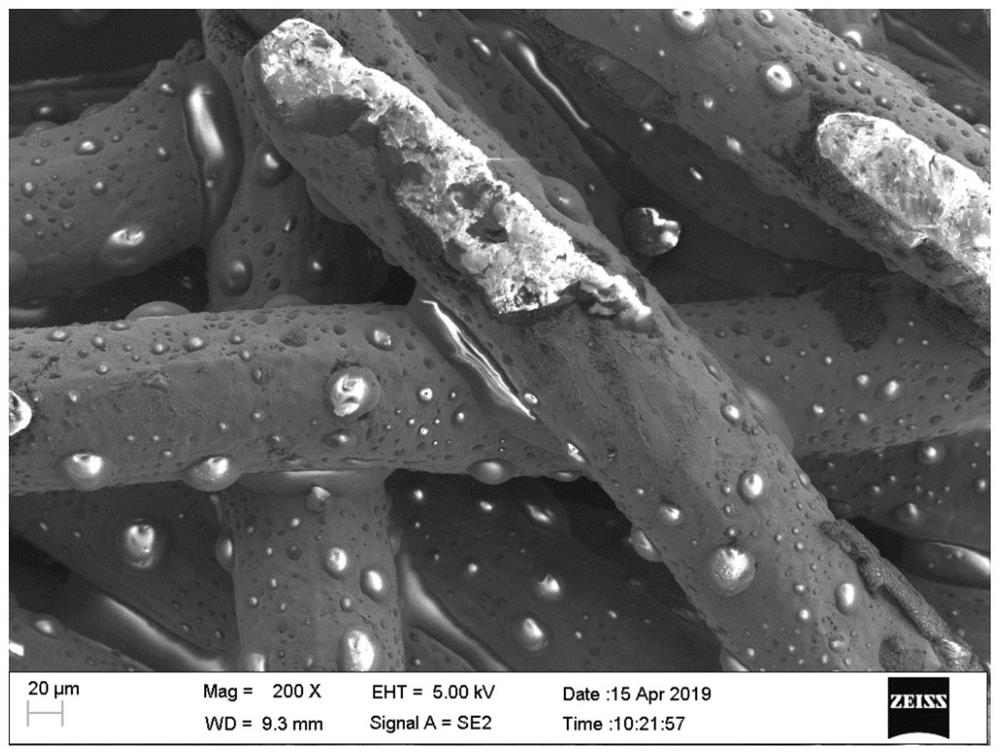

[0026] Stainless steel fibers prepared by turning method. First, use alkaline degreaser to clean the stainless steel bar, and then cut and remove the surface scale after clamping it on the lathe. Then replace it with a multi-tooth cutter with a large blade inclination angle, and cut stainless steel fibers on a lathe. The knives are machined from ultra-hard high-speed steel.

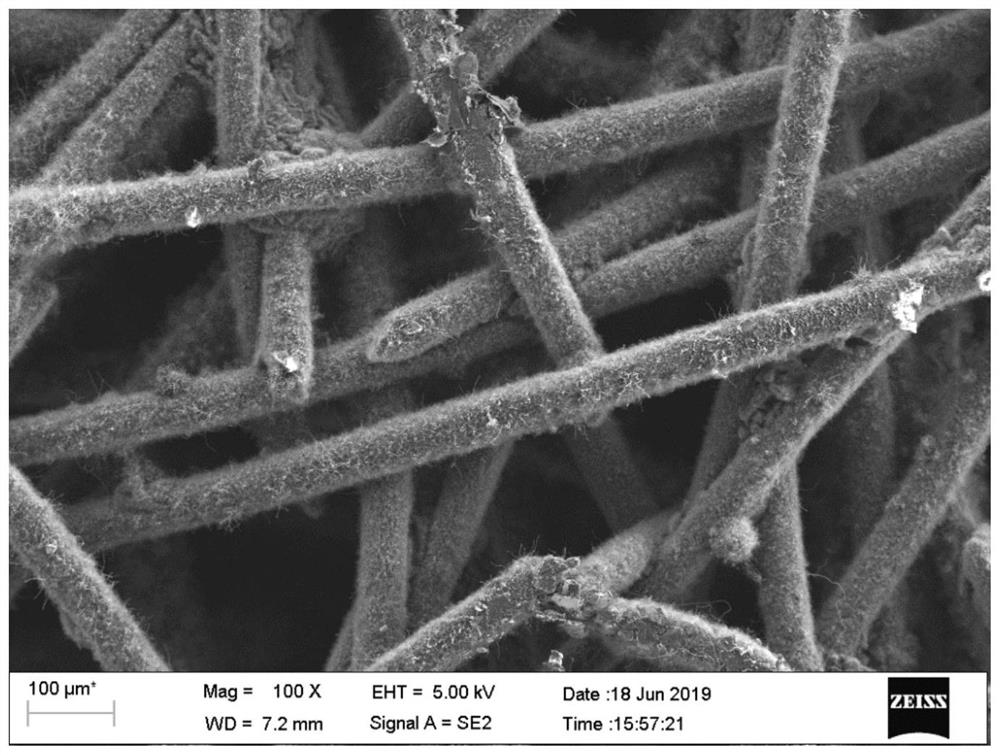

[0027] Cut the stainless steel fibers with a diameter of about 70-150 μm to a length of about 10mm; wash the short stainless steel fibers with a NaOH solution with a mass concentration of 5%-10% for 5-10min, and then wash them with deionized water and place them in a volume concentration 5-10% dilute HC 1 Soak in the solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com