Preparation method and application of expanded perlite loaded gold nanoparticle catalyst

A technology of expanded perlite and nano-gold particles, used in catalyst activation/preparation, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc. High price, large waste of gold and other problems, to achieve the effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

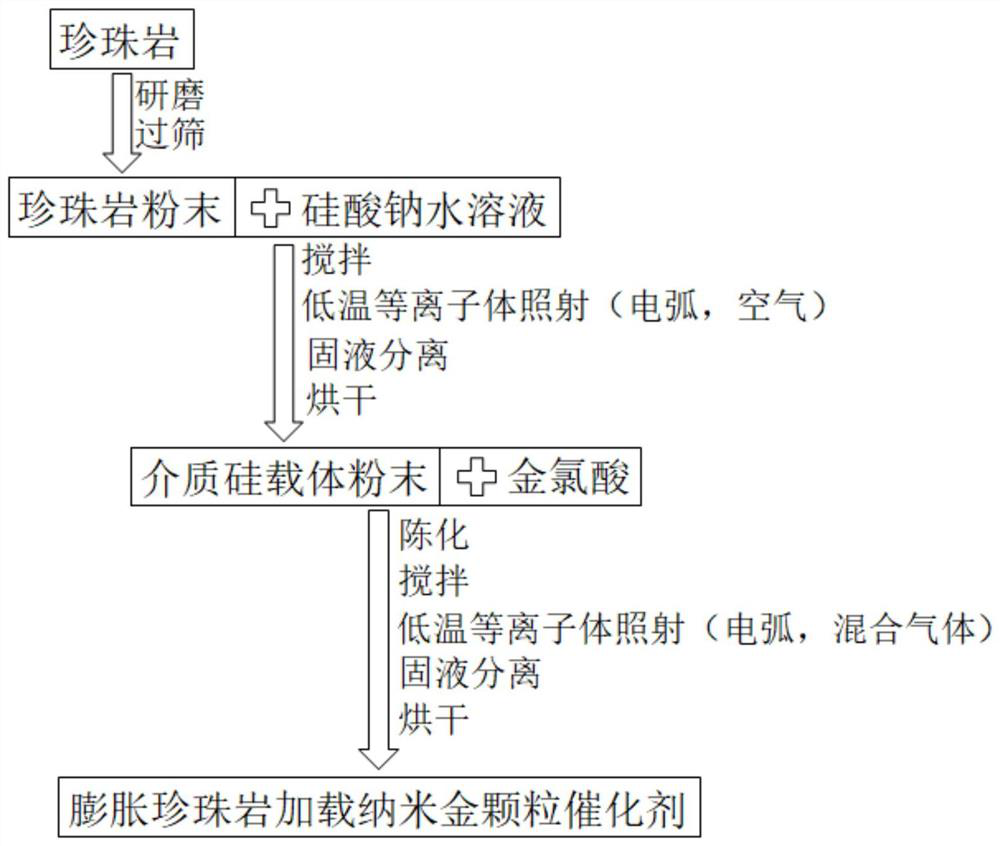

Method used

Image

Examples

Embodiment 1

[0023] Example 1 Effect of solid content of sodium silicate on the catalytic performance of the prepared expanded perlite-loaded nano-gold particle catalyst

[0024] The expanded perlite is ground and passed through a 200-mesh sieve to obtain expanded perlite powder. According to the solid-liquid ratio of 0.3mg / mL, mix the expanded perlite powder into the sodium silicate aqueous solution with a solid content of 10%, 15%, 18%, 20%, 30%, 40%, 42%, 45%, and 50%. In the process, stirring at 60rpm, low-temperature plasma irradiation for 0.5 hours at the same time, solid-liquid separation, and drying at 50°C, nine groups of dielectric silicon carrier powders were obtained. The low-temperature plasma irradiation voltage was 10kV, and the irradiation method was arc Discharge, low temperature plasma aeration atmosphere is air. According to the solid-liquid ratio of 0.6 mg / mL, the nine groups of medium silicon carrier powders were mixed into the chloric acid, aged for 12 hours, then st...

Embodiment 2

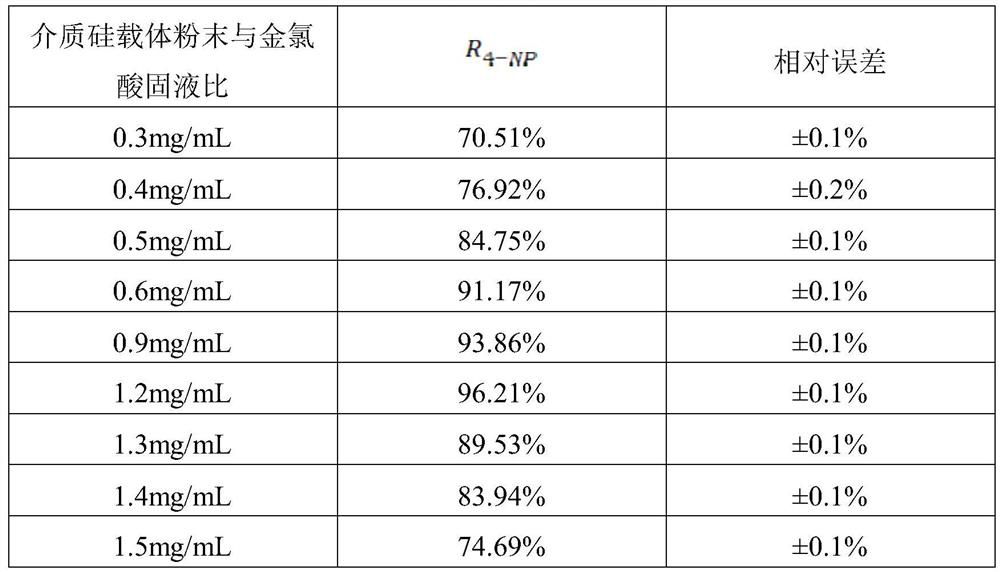

[0031] Example 2 The effect of the solid-liquid ratio of medium silicon carrier powder and auric acid on the catalytic performance of the prepared expanded perlite-loaded nano-gold particle catalyst

[0032]The expanded perlite is ground and passed through a 300-mesh sieve to obtain expanded perlite powder. According to the solid-liquid ratio of 0.75mg / mL, the expanded perlite powder was mixed into the sodium silicate aqueous solution with a solid content of 40%, stirred at a rate of 210rpm, and low-temperature plasma was irradiated for 1 hour at the same time, and the solid-liquid separation was carried out at 100°C. The dielectric silicon carrier powder is obtained by drying under the lower pressure, wherein the low-temperature plasma irradiation voltage is 20kV, the irradiation method is arc discharge, and the low-temperature plasma aeration atmosphere is air. According to the solid-liquid ratio of 0.3mg / mL, 0.4mg / mL, 0.5mg / mL, 0.6mg / mL, 0.9mg / mL, 1.2mg / mL, 1.3mg / mL, 1.4mg / ...

Embodiment 3

[0037] Example 3 Effect of Hydrogen Content in Mixed Gas on the Catalytic Performance of the Prepared Expanded Perlite-loaded Nano-gold Particle Catalyst

[0038] The expanded perlite is ground and passed through a 200-mesh sieve to obtain expanded perlite powder. According to the solid-liquid ratio of 1.2mg / mL, the expanded perlite powder was mixed into the sodium silicate aqueous solution with a solid content of 40%, stirred at a rate of 360rpm, and irradiated with low-temperature plasma for 1.5 hours at the same time, separated from solid and liquid, at 150°C The dielectric silicon carrier powder is obtained by drying under a lower temperature, wherein the low-temperature plasma irradiation voltage is 30kV, the irradiation method is arc discharge, and the low-temperature plasma aeration atmosphere is air. According to the solid-liquid ratio of 1.2 mg / mL, the dielectric silicon carrier powder was mixed into the hydrochloric acid, aged for 24 hours, then stirred at a rate of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com